There is a growing need for accurate vibration isolation with scanning probe microscopy (SPM) and nearfield scanning optical microscopy (NSOM) systems and is becoming highly critical as resolutions bridge from micro to nano. SPM and NSOM systems are highly susceptible to environmental vibrations whether used in commercial facilities or in academic labs.

It is essential to establish a stable surface for the instrument while measuring displacements of very few nanometers or angstroms. Any vibration coupled with the instrument’s mechanical structure will cause vertical and/or horizontal noise and thus reduce the system's ability to measure high resolution features. And while the vertical axis is the most sensitive for SPMs, they can also be quite sensitive in the horizontal axis.

Traditional Isolation

Conventionally, high performance air tables and bungee cords have been the vibration isolators most used for SPM and NSOM work. The ubiquitous passive-system air tables, adequate until around 10 years back are being challenged seriously by the need for more refined imaging. Benchtop air systems offer limited vertical and horizontal isolation.

Air tables that have been used liberally for optics applications, are not ideal for these nanoscale resolution systems due to their inability to effectively isolate vibrations below 20 Hz.

However, negative-stiffness mechanism (NSM) vibration isolators are becoming the preferred choice for SPM and NSOM systems.

AFM with Micro-Raman

Combining AFM and Micro-Raman permits a sizable improvement in data correlation between the two techniques and expanded Raman measurement and resolution capabilities.

Micro-Raman is a spectroscopic NSOM technique, which is used in condensed-matter physics and chemistry to study rotational, vibrational, and other low-frequency modes in a system. It depends on monochromatic light scattering normally from a laser in the near-infrared, visible, or near ultraviolet range. The laser light and phonons or other excitations in the system interact with each other, resulting in the energy of the laser photons being shifted up or down. The energy shift offers information about the phonon modes in the system.

There are several problems while scanning samples in a micro-Raman system. It is difficult to keep the lens-to-sample distance constant even when a flat sample is scanned. As one moves from pixel to pixel under a Raman lens, a mixture of sample and air is sampled in the voxel (volumetric picture element) that is illuminated.

This results in artifactual intensity variations in the Raman that are not related to the sample’s chemical composition. Also the point-spread function is broader where there are contributions from the out-of-focus light, and this reduces resolution.

The AFM is a very high-resolution scanning probe microscope demonstrating resolution of a fraction of a nanometer making it the foremost tools for imaging, measuring, and manipulating matter at the nanoscale.

The AFM includes a microscale cantilever with a sharp tip (probe) at its end that is used to scan the specimen surface. The cantilever is silicon nitride or silicon with a tip radius of curvature on the order of nanometers. When the tip is brought close to the sample surface, forces between the tip and the sample result in deflection of the cantilever.

Resultant characteristics, such as mechanical, electrostatic, magnetic, chemical and other forces are then determined using the AFM, typically, a laser spot reflected from the top surface of the cantilever into an array of photodiodes.

Most systems that make use of AFM along with Raman perform separately, executing either an AFM scan or a Raman scan independently. The recently developed direct integration of Raman spectroscopy with AFM technique, however, has opened the door to significantly improved techniques and sample analyses.

Micro-Raman is a microtechnique, however the addition of AFM makes it a nano technique. The AFM structural data is recorded online and the resolution of the Raman information when the nanometric feedback of the system is adjusted is improved with unprecedented precision, the position of each pixel of the sample relative to the lens.

Also the tiny movements of the AFM stage enable over sampling, which is a well-known technique for resolution improvement.

Integrated AFM-Raman System

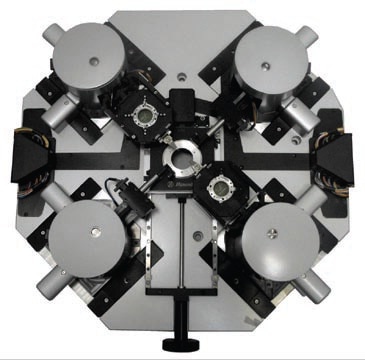

An integrated AFM-Raman system developed by Nanonics Imaging along with major Raman manufacturers such as Renishaw plc, Horiba JY and others offer simultaneous and, very importantly, on-line data from both modalities as shown in Figure 1.

Figure 1. The MicroView4000 platform from Nanonics Imaging is the basis for AFM-Raman integration.

This benefit addresses critical issues in Raman that include intensity and resolution comparisons in Raman images while permitting on-line functional characterization such as thermal conductivity, elasticity and adhesion, electrical and other properties.

It also enables new areas of improved resolution including AFM functioning without optical obstruction, parallel recording with Raman in a wide variety of scanned probe imaging modalities enabling direct and simultaneous image comparison and analysis, and high-resolution Raman mapping.

The Nanonics platform can be used for structural and photonic characterization, as well as the structural and chemical characterization that is available with AFM and Raman integration. For these applications, Nanonics Imaging is the innovator of AFM and NSOM systems, including dual tip/sample scanning AFM systems, the industry's first NSOM-AFM cryogenic systems, integrated Raman-AFM systems, multiprobe AFM and SEM-AFM systems.

The Nanonics MultiView AFM-NSOM microscope, with its free optical axis on a standard micro-Raman, helps in combining the separate worlds of Raman and AFM/NSOM nanocharacterization, which has led to a new era in high-resolution Raman spectroscopy.

NSVI Enables Integration

Negative-stiffness vibration isolation is the underlying technology of this pioneering integration of AFM with micro-Raman. The negative-stiffness isolators offer improved transmissibility that is the vibrations transmit through the isolator relative to the input floor vibrations. Transmissibility with negative-stiffness is considerably improved over air systems and over active isolation systems.

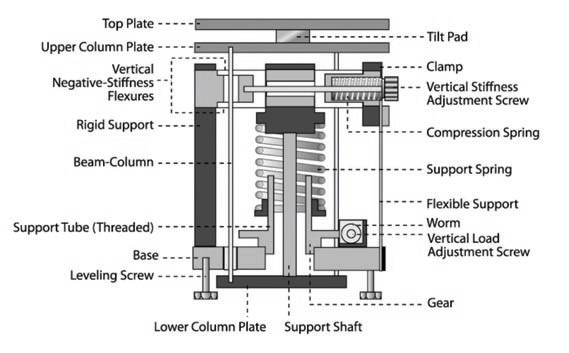

Negative stiffness isolators use a completely mechanical, unique concept for low-frequency vibration isolation. A stiff spring supporting a weight load combined with a negative stiffness mechanism offers vertical motion isolation as shown in Figure 2. The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring.

Figure 2. The negative-stiffness isolator concept developed by Minus K Technology makes it possible for a heavy AFM-Raman system to be immune to shocks that would make nanoprecision impossible.

The beam column effect reduces the horizontal stiffness of the beam columns. The result is a compact passive isolator that have very low vertical and horizontal natural frequencies and very high internal structural frequencies. The isolators (adjusted to 1/2 Hz) achieve 93% isolation efficiency at 2 Hz; 99% at 5 Hz; and 99.7% at 10 Hz.

About Minus K Technology

Minus K® Technology, Inc. was founded in 1993 to develop, manufacture and market state-of-the-art vibration isolation products based on patented negative-stiffness technology. Minus K® is based in the Los Angeles area.

The Minus K® products, formerly sold under the trade name Nano-K®, represent an important enabling technology. By reducing building and floor vibrations to unprecedented levels these systems enable vibration sensitive instruments and equipment to perform at unprecedented levels.

They are used in a broad spectrum of applications including nanotechnology, biological sciences, semiconductors, materials research, zero-g simulation of spacecraft, and high-end audio. Minus K® is an OEM supplier to leading manufactures of scanning probe microscopes, micro-hardness testers and other vibration-sensitive instruments and equipment. Minus K® customers include private companies and more than 200 leading universities and government laboratories in 41 countries.

Dr. David L. Platus is President and Founder and is the principal inventor of the technology. He earned a B.S. and a Ph.D. in Engineering from UCLA, and a diploma from the Oak Ridge School of (Nuclear) Reactor Technology. Prior to founding Minus K® Technology he worked in the nuclear, aerospace and defense industries conducting and directing analysis and design projects in structural-mechanical systems. He became an independent consultant in 1988. Dr. Platus holds over 20 patents related to shock and vibration isolation.

This information has been sourced, reviewed and adapted from materials provided by Minus K Technology.

For more information on this source, please visit Minus K Technology.