From MicrotracReviewed by Emily MageeJun 25 2025

In this interview, AZoNano speaks with Serife Korkmaz, Turbiscan Product Manager at Microtrac, about optimizing lithium-ion battery slurry stability using Turbiscan technology.

Can you please introduce yourself and your role at Microtrac?

My name is Serife Korkmaz, and I work as the Turbiscan Product Manager at Microtrac. I'm based in our Toulouse facility in France, where I am responsible for the strategy, roadmap, and feature definition of the TURBISCAN range.

My role involves coordinating across teams to deliver valuable products that meet customer and industry needs, including battery slurry optimization. With a background in chemistry and formulation science, I ensure users gain meaningful, accurate insights from their stability measurements.

What are the key challenges in lithium-ion battery slurry stability?

Due to their complex formulations, lithium-ion battery slurries present several challenges. It is crucial to achieve high performance while maintaining environmental friendliness, cost-effectiveness, and compatibility with existing processes.

The slurry's stability is influenced by factors such as binder solubility, viscosity, and the tendency of components like carbon black to agglomerate. Instabilities like sedimentation or aggregation can lead to non-homogeneous electrode films, negatively impacting battery performance.

Image Credit: tomeqs/Shutterstock.com

How does Turbiscan technology address these challenges?

Turbiscan utilizes Static Multiple Light Scattering (SMLS) to monitor stability without altering the sample. By scanning from the bottom to the top of a sample vial, it detects changes in transmitted and backscattered light, indicating particle migration or aggregation. This allows for the identification of destabilization phenomena like sedimentation or creaming much faster than visual observation, providing objective and quantitative data on slurry stability.

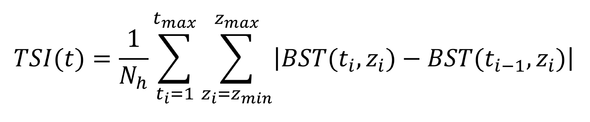

Can you explain the Turbiscan Stability Index (TSI) and its relevance?

The Turbiscan Stability Index (TSI) is an algorithm that quantifies the overall stability of a sample by summing all variations detected in backscattering profiles over time. A higher TSI indicates greater instability. This single, user-independent parameter enables formulators to rank and compare the stability of different formulations quickly, facilitating faster decision-making in the development process.

Image Credit: Microtrac

Could you share a case study where Turbiscan improved slurry formulation?

Certainly. In one study, we compared cathode slurries formulated with two different carbon blacks from separate suppliers. Turbiscan measurements revealed that the slurry with carbon black from supplier one exhibited higher sedimentation, as indicated by a higher TSI value, compared to supplier two. This insight allowed the formulation team to select the more stable carbon black, optimizing the slurry's performance.

How does Turbiscan assist in process optimization beyond formulation?

Turbiscan can monitor batch-to-batch variations and the effects of storage or mixing processes on slurry stability. For instance, by analyzing slurries from different batches, we observed that some exhibited higher sedimentation intensity shortly after preparation, indicating instability. This information helps in adjusting mixing protocols or storage conditions to ensure consistent slurry quality before electrode fabrication.

What role does Turbiscan play in developing greener battery formulations?

In efforts to replace harmful solvents like NMP with greener alternatives, Turbiscan can be combined with the Hansen solubility approach. By measuring the stability of slurries in various solvents, we can construct a Hansen solubility sphere to identify suitable green solvents that maintain or improve slurry stability. This method accelerates the screening process for environmentally friendly solvent options.

What are the sample requirements and measurement conditions for Turbiscan?

Turbiscan requires a minimum sample volume of 15 to 20 milliliters. It can analyze samples with concentrations up to 95 % in volume fraction, accommodating highly concentrated slurries. The instrument operates at temperatures up to 80 degrees Celsius, allowing for accelerated stability studies or the simulation of processing conditions.

How does Turbiscan compare to traditional stability assessment methods?

Traditional methods often rely on visual observation, which can be subjective and time-consuming. Turbiscan provides objective, quantitative data on stability much faster, detecting early signs of destabilization that might be missed visually. Its ability to analyze samples without dilution preserves the native state of the slurry, leading to more accurate assessments.

About Serife Korkmaz

Serife Korkmaz is the Turbiscan Product Manager at Microtrac, specializing in particle characterization technologies. Based in Toulouse, France, she defines the strategy, roadmap, and new features development for the Turbiscan range. Serife has an engineering degree in chemical formulation from the École Nationale Supérieure de Chimie de Lille (ENSCL) and a master's degree in polymer systems engineering from the University of Lille.

Her professional experience includes roles in research and development at Bollig & Kemper France and Sika, focusing on industrial coatings and adhesive formulations, as well as quality control experience at Çaglayan Kimya in Turkey. Her expertise lies in colloidal and physical stability, with a strong chemistry background that aids in analyzing how particle size, zeta potential, and stability interrelate to optimize formulations and product development.

This information has been sourced, reviewed and adapted from materials provided by Microtrac.

For more information on this source, please visit Microtrac.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.