Physik Instrumente’s Parallel photonics alignment technology comprises a suite of advanced firmware-level algorithms integrated into the company’s highest-performance motion controllers for 6DOF hexapods and nanopositioning multi-axis scanners.

These algorithms optimize fast optical coupling between photonic and other optical components and assemblies across multiple degrees of freedom, inputs, outputs, elements, and channels. Many of these optimizations can run concurrently, even when the parameters interact.

The result is a significant reduction in process time in applications such as testing and assembly of LiDAR sensors, smartphone camera modules, and advanced silicon photonics devices.

Serial Versus Parallel Alignment Strategies

In silicon photonics (SiP) devices, short waveguides' input and output couplings are often interdependent; adjusting one side can perturb the other, necessitating re-optimization.

Traditionally, achieving optimal coupling required an iterative, serial alignment process: repeated adjustments of the input and output channels in alternating sequence until a global alignment “consensus” was reached. A similar issue arises when optimizing angular alignment, where any improvement in pitch, yaw, or roll affects the transverse position, triggering yet another optimization loop. These nested, serial iterations result in extended process times and reduced throughput.

PI’s Fast Multi-Channel Photonics Alignment (FMPA) technology eliminates this bottleneck by enabling concurrent, parallel optimization of all interacting degrees of freedom. The system can simultaneously adjust input, output, angular, and lateral parameters, rapidly converging toward a true global optimum.

This approach allows global consensus alignment to be established in a single step. Moreover, FMPA can maintain active tracking and continuous correction during production, compensating for drift, curing stresses, and other dynamic effects.

The outcome is a substantial increase in manufacturing throughput and process stability, along with a measurable reduction in cost per device. As photonic components grow more complex and alignment tolerances tighten, the benefits of true parallel optimization become increasingly critical to competitive process economics.

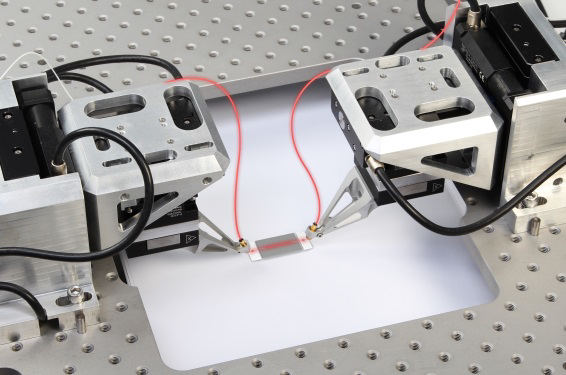

Fig 1. Aligning the inputs and outputs of waveguide devices at an industrial pace requires parallel optimization and nanoscale accuracy. Image Credit: PI (Physik Instrumente) LP

Look for the Loops

To fully utilize this capacity for maximum overall cost reductions, some different thinking may be required than what is typical of classical alignment hardware.

Generally, one looks for sequential alignment loops that can be replaced with simultaneous improvements. This article examines a few sample applications and addresses implementation challenges to demonstrate how this astonishing new capability may boost productivity in testing and packaging.

Background of FMPA Operation

The device alignment should be divided into discrete alignment operations. For example, probing a waveguide with one input and one output using a lensed fiber usually requires four alignment processes:

- Transverse optimization routine, input

- Transverse optimization routine, output

- Z optimization routine, input (beam waist seek)

- Z optimization routine, output (beam waist seek)

If the device has one or more extra inputs or outputs, add as follows:

- Theta-Z optimization routine, input

- Theta-Z optimization routine, output

If the device needs optimization in theta-X and theta-Y, include:

- Gimbaling optimization routine, input

- Gimbaling optimization routine, output

Breaking down the overall alignment task into subprocesses is essential for identifying which steps can run simultaneously.

With FMPA, users start by listing their alignment routines and defining them directly in the controller. This setup only needs to occur once - though you can update or modify it anytime. Once a routine is defined, it becomes repeatable. Better yet, multiple routines can run simultaneously, and this is where parallelism comes in.

Defining a process involves telling the controller which axes are involved, specifying which analog input reflects the quantity to be optimized (such as optical power or MTF), and selecting various process options. Users should name each process.

Users can run routines using the Fast Routine Start (FRS) command. For example, FRS 1 starts the transverse optimization on the input, FRS 2 starts the transverse optimization on the output, and FRS 1 2 runs both simultaneously.

Types of Alignment Routines

Independent alignment engine hardware is required on each side of the device. Any number of alignment engines can be employed; the most frequent configurations use one or two, but three or more will become more popular as SiP technology advances.

Typically, each alignment engine consists of a multi-axis long-travel assembly and a shorter-travel, high-speed, high-resolution piezoelectric multi-axis nanopositioning stage.

The technique's modularity is a significant advantage. Some applications do not require the lengthy trip mechanism or the nanopositioning stage's speed, precision, or continuous tracking capability.

In each event, regardless of the type of motion system used, all FMPA algorithms and processes are nearly the same; the only difference is the capability.

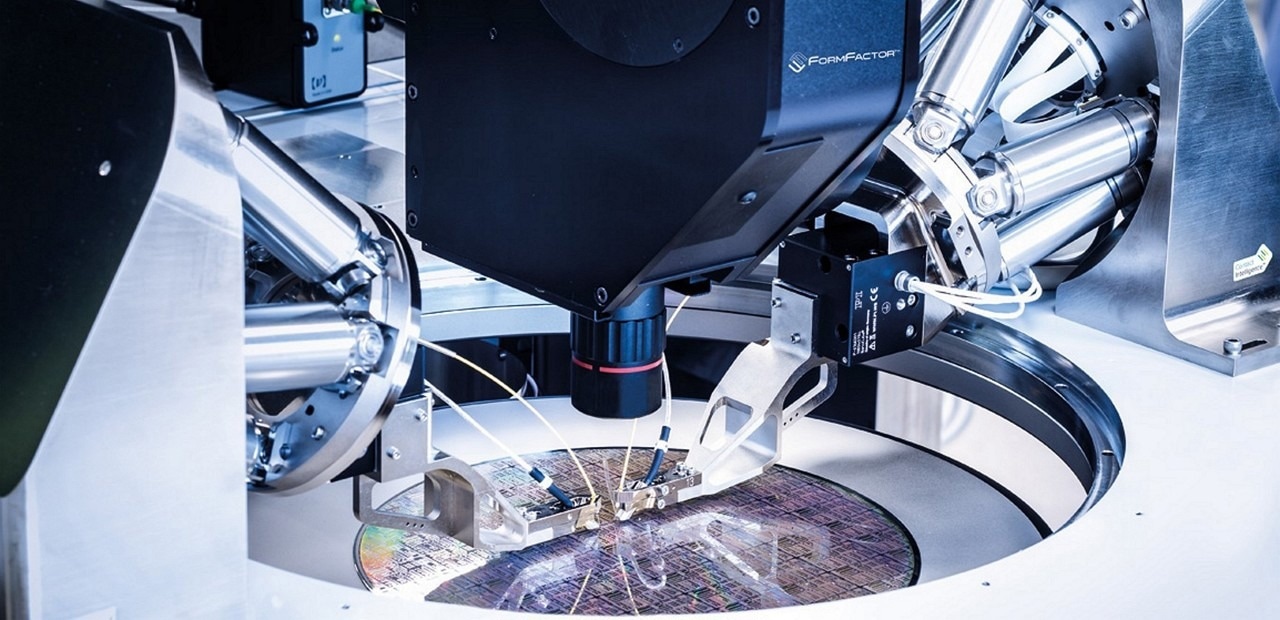

Fig 2. F-712.HA2, dual hexapod alignment system mounted on a FormFactor silicon photonics wafer prober. Image Credit: FormFactor

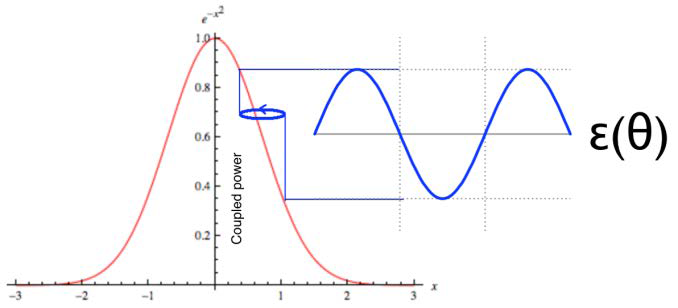

Fig 3. Video explaining parallel alignment: Dividing a task like waveguide I/O coupling into sub-tasks like “1” and “2”, as shown, will illuminate opportunities for parallel execution. Here, the two processes can proceed in parallel even though they interact, especially in the case of short waveguides where inputs and outputs steer each other. Similarly, processes related geometrically (such as a transverse and Z optimization in situations such as those shown with an angled beam) can be performed in parallel. Image Credit: PI (Physik Instrumente) LP

Fig 4. NanoCube®, piezo-based, high dynamic, 3-axis scanner with 100 μm travel range. Besides its nanoscale resolution and blazing speeds, this flexure-based subsystem can perform continuous tracking without wear. Image Credit: PI (Physik Instrumente) LP

Long Travel Options

A stack of linear stages is sufficient for scenarios without angular optimizations or array alignment.

A hexapod is required otherwise, not only in situations requiring full six-degree-of-freedom positioning and optimization, but also in simpler situations, because the hexapod allows the rotational center point of even a single angular optimization to be placed on the optical axis, at the beam waist, and so on.

This is critical for eliminating parasitic geometric errors, which are another key to increasing overall productivity.

Sometimes, very long travel in one or two axes is required for loading operations, in which case the hexapod can be installed on a long-travel motorized stage. The hexapod controller can accommodate two extra DC servomotor axes. Alternatively, force sensor components can be included.

Fig 5. Single-sided fiber alignment system. Image Credit: PI (Physik Instrumente) LP

The Alignment Processes

There are two sorts of processes: areal scans, which aim to pinpoint a peak within a specific region, and gradient searches, which aim to efficiently improve coupling (and optionally follow it to reduce drift processes, disturbances, and so on).

Gradient Searches

Gradient searches cause a slight circular dither motion of one device versus the other, modulating the coupling. The amount of modulation of the figure-of-merit being optimized (for example, optical power or MTF) represents the local gradient of the coupling. At optimal, the modulation is zero (Fig. 6).

Fig 6. Graphical depiction of gradient determination via a circular dither, which modulates the coupled power (or other quantity) observed. The phase of the modulation with respect to the dither indicates the direction towards maximum, while its amplitude falls to 0 at optimum. Image Credit: PI (Physik Instrumente) LP

|ε(θ)|=∇I=(Imin-Imax)/Imin

Equation 1. The observed gradient serves as a measure of alignment error.

The local gradient can be quantitatively deduced from the observed modulation using a simple computation, such as Equation 1. At optimal, the gradient ∇I equals zero. Any axes in an FMPA system can accomplish any of these alignments (according to their physical limitations, of course).

As a result, areal scans can be performed using motorized stage axes, which can be quite useful for detecting first light.

Gradient searches are most commonly associated with transverse optimization, although they can also be performed (for example) in a single linear axis, which is perfect for localizing the beam waist in a lensed coupling, or in a gimbaling fashion to optimize an angle.

Numerous possibilities exist. These are extremely versatile algorithms that can be used for a wide range of optimization tasks, including bulk optic, cavity, and pinhole alignments.

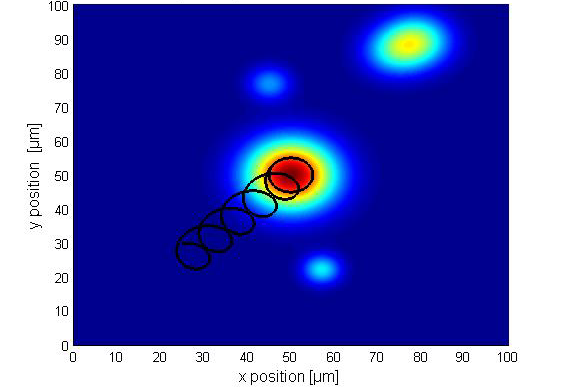

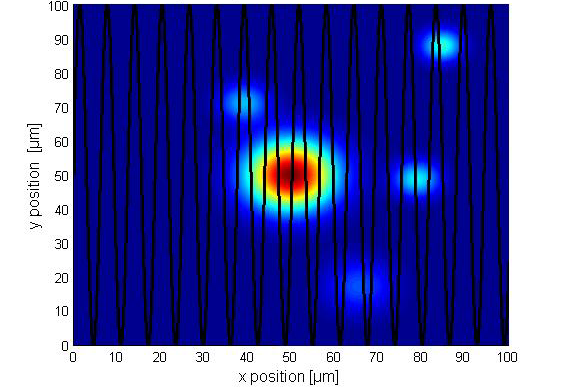

Fig 7. Optical power distribution. Image Credit: PI (Physik Instrumente) LP

FMPA is distinguished by the ability to run several gradient searches simultaneously. Transverse optimizations are typically the most delicate and impacted by other alignments. As a result, transverse routines are usually restricted to high-speed, high-resolution piezoelectric stages like PI's P-616 nanoCube.

The NanoCube's fast speed and continuous tracking capacity maintain transverse optimization during Z and angular optimizations, which would otherwise necessitate a time-consuming, looping sequential approach.

Areal Scans

Scanning an area to discover the approximate location of the highest coupling peak is beneficial for a variety of purposes:

- Seeking the first light

- Profiling a coupling to determine its dimensions. This could be a critical process control step.

- Localizing the principal mode of a coupling for optimization via gradient search. This hybrid technique is particularly effective in preventing locking-on to a local maximum.

In addition to reducing the areal scan to a single command, FMPA controllers provide automatic curve-fitting capabilities and a data recorder that can capture the profile on the fly for subsequent retrieval, analysis, or databasing.

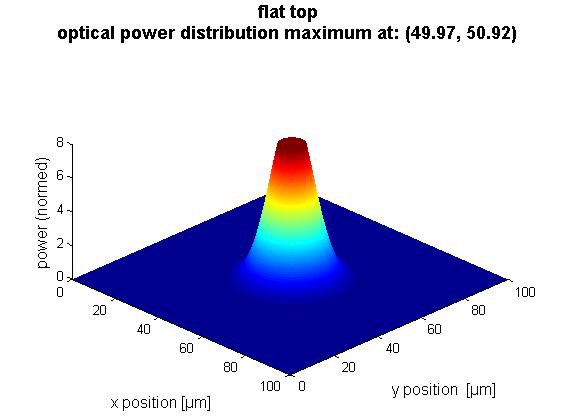

FMPA areal scans are very quick, taking about 300 msec for common NanoCube applications and loads. The curve-fitting capacity can fit a Gaussian to a relatively sparse scan (i.e., a quick scan), allowing for good localization of the optimal coupling point without spending a long time to do a very fine scan.

Another capacity is determining the centroid of a flat-top ("top-hat") coupling, such as when probing a deposited photodetector with a single-mode fiber. This permits the scan to end with the fiber at the geometric center of a flat or inclined top-hat coupling.

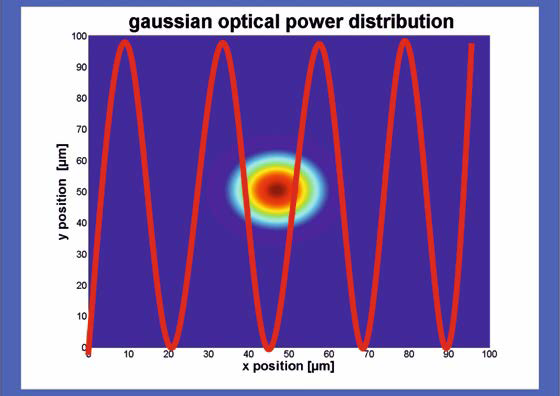

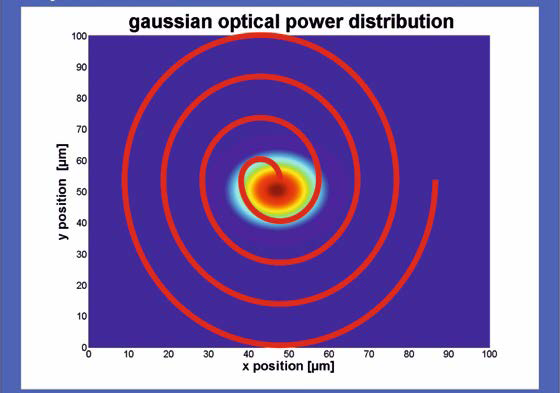

Fig 8. Optical power distribution. Image Credit: PI (Physik Instrumente) LP

FMPA offers unique areal scan possibilities, including single-frequency sinusoid and spiral scans. These are far faster than typical raster or serpentine scans because they are really continuous, eliminating the settling requirements of traditional scans' stop-and-start motions. The frequency can be adjusted to prevent triggering structural resonances.

A constant-velocity spiral scan may also be chosen, allowing data to be collected with a consistent density over the spiral.

Fig 9. Sinusoidal area scan. Image Credit: PI (Physik Instrumente) LP

Fig 10. Spiral area scan. Image Credit: PI (Physik Instrumente) LP

Fig 11. Uniquely, PI FMPA controllers can perform a fast areal scan and automatically calculate and align robustly to the centroid position of upright and tilted top-hat couplings. Image Credit: PI (Physik Instrumente) LP

Wafer Probing of Angle-Insensitive Devices

Even in the most basic scenario of a short waveguide device with only one input and output, the steering interaction described above can be a bothersome process bottleneck. Add the additional alignments required for angle-sensitive couplings and array devices, and the issue soon becomes complex and time-consuming.

Parallelism mitigates all of this and speeds up the process. For this example, consider a planar waveguide with a single input and output, both of which can be probed using diffractive couplers. Many thousands of such devices are typically manufactured on big wafers, so throughput is critical.

The diffractive couplers typically project the waveguide's input and output out of the wafer at an angle of 10-25° from vertical. Lensed probe fibers are frequently employed, resulting in a clear optimal separation along the optical axis.

High-quality wafer probers have lower placement accuracies than the NanoCube's 100 µm × 100 µm × 100 µm field of vision, eliminating the requirement for first light seeks per device in probing applications. Note that the optical Z axis is at an angle to the mechanical Z axis for conventional stage stack placement.

To minimize collisions, the mechanical XY plane should stay parallel to the wafer, so tilting the motion assembly to accommodate the tilted optical beam is typically not ideal. As a result, optimization motions in mechanical Z must be followed by compensating motions in X and Y to maintain alignment.

This is a perfect example of parallelism. The first four alignment routines in the generic list compiled above apply:

- Transverse optimization routine, input

- Transverse optimization routine, output

- Z optimization routine, input (beam waist seek)

- Z optimization routine, output (beam waist seek)

Using non-parallel alignment technology, the normal approach would be:

1. To accommodate  , loop:

, loop:

- To accommodate steering effects, loop:

-

- Align one side to maximize throughput

- Align the other side to maximize throughput

- Move in Z and evaluate if the move direction improved coupling

2. Repeat the above loops until optimized.

The total time required is often many tens of seconds! FMPA makes the procedure significantly easier and can be two or more orders of magnitude faster. Fundamentally, one defines gradient searches 1-4 from the list (again, this only needs to be done once, but any process may be tweaked or re-defined arbitrarily), and then for each device:

- Issue the Fast Routine Start command: FRS 1 2 3 4

Execution is normally completed in a few hundred milliseconds. A single E-712 controller can support up to four P-616 NanoCubes, which can be put on various workstations and do not have to process the same device.

Fig 12. E-712 digital piezo controller. Image Credit: PI (Physik Instrumente) LP

Tracking and the Completion Criterion

The gradient search has the unique advantage of optimizing and tracking its optimum. If you run many gradient searches on a device, they might all track simultaneously.

Alternatively, you may want to align first, then stop and hold in the optimal position for your application. This criterion - whether to align and stop or continue tracking - is an example of a parameter you may change in the process description to fine-tune the process's behavior to fit your application's requirements; there are other such alternatives.

Because the process is dependent on the instantaneous gradient of the coupling, it is logical to describe its endpoint in terms of the gradient.

This is called the Minimum Level, or ML. Setting the process's ML parameter to 0 indicates that it should never be satisfied and should continue to track until instructed to quit. This is important for handling drift processes, such as elevated temperature testing.

Setting ML to a small but non-zero value causes the gradient search to end at the observed optimal point. Due to the possibility of mechanical wear, ML=0 tracking should only be used with flexure-guided systems.

This information has been sourced, reviewed and adapted from materials provided by Physik Instrumente.

For more information on this source, please visit Physik Instrumente.