Process Monitoring with Spatially Resolved DLS

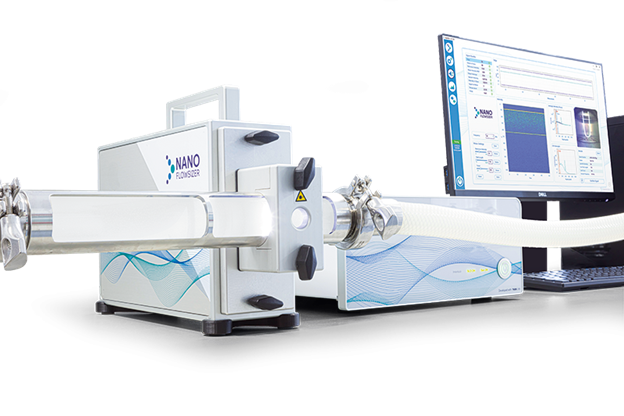

The NanoFlowSizer is a groundbreaking Process Analytical Tool (PAT) designed for non-invasive, real-time characterization of nanoparticles. Using our proprietary Spatially Resolved Dynamic Light Scattering (SR-DLS) technology, the NanoFlowSizer provides accurate particle size distribution analysis across a wide range of sample turbidity levels. Whether in R&D, pilot, or full-scale manufacturing, this modular system seamlessly integrates inline, online, at-line, or offline to optimize your process efficiency.

Key Features

✅ Continuous real-time measurement of nanoparticles during processing

✅ Inline, online, at-line, and offline adaptability

✅ Hydrodynamic diameter & size distribution (D10, D50, D90, PDI)

✅ Compatible with highly turbid materials

✅ Non-invasive measurement in any container (e.g., syringes, vials, and flow cells)

✅ GMP-compliant software (XsperGo) with OPC-UA compatibility

✅ Fully customizable for lab, pilot, and manufacturing scales

Why Choose the NanoFlowSizer?

- Next-level process monitoring

- Unique Process Analytical Technology (PAT) solution

- Ultra-fast measurement (<5 sec per data point)

- Efficient data management

- Reduced risk of batch failures

- Cost-effective real-time monitoring

Technical Specifications

| Parameter |

Specifications |

| Measurement Principle |

Spatially Resolved DLS (SR-DLS) |

| Particle Size Range |

15 nm - 5000 nm |

| Turbidity Compatibility |

Low to very high |

| Measurement Modes |

Inline, online, at-line, offline |

| Flow Rate |

Up to 250L/hr |

| Data Collection |

Real-time, <5 sec per data point |

| Supported Particles |

LNPs, (in)organic particles, Milled API, protein, mAb, pAb, ADC |

| Software |

XsperGo (GMP features, PhaSR) |

| Probe Unit Dimensions |

25 x 35 x 10 cm |

Industry Applications

- Pharmaceuticals & Biotech – LNPs, proteins, antibodies, APIs

- Nanomaterials – Inorganic and organic nanoparticles

- Chemical & Food Industries – Emulsions, suspensions, dispersions

- Advanced Manufacturing – Continuous flow production

What InProcess' Users Say

"We were searching for an instrument that could perform non-invasive measurements, such as analysis directly within syringes. With the NanoFlowSizer, this is now a reality."