In this interview, Alistair Kean, founder of Nikalyte Ltd, talks to AZoNano about the nanotechnology tool the NL50.

Can you give us an introduction to the new product you just launched – the Nikalyte NL50?

The NL50 is focused on nanotechnology, including nanomaterials, nanosurfaces, and nanoparticles, which are of enormous interest to scientists researching in many different areas. Nanomaterials can affect many things, e.g., physical and chemical properties. Therefore, we wanted to design an instrument that addresses these areas.

Primarily, it is a research instrument. We realized that there is a market for a compact instrument that could generate nanomaterials, and more importantly, an instrument that anyone could use. Previously such equipment was used by highly qualified physicists who could operate complex equipment. However, we realized that one of our materials' biggest markets is life sciences, which requires operation on a routine push-button platform.

We decided to use our experience to simplify the technology to an extent where we can teach anyone how to use the instrument in just 10 minutes. Therefore, you do not have to be concerned about how you make the nanomaterials – we could even bring the production of nanomaterials to the masses.

What makes the NL50 the ideal multi-user tool?

We are using electrostatics, plasma, gases, all kinds of things to make these nanoparticles. However, it is a very straightforward tool to use.

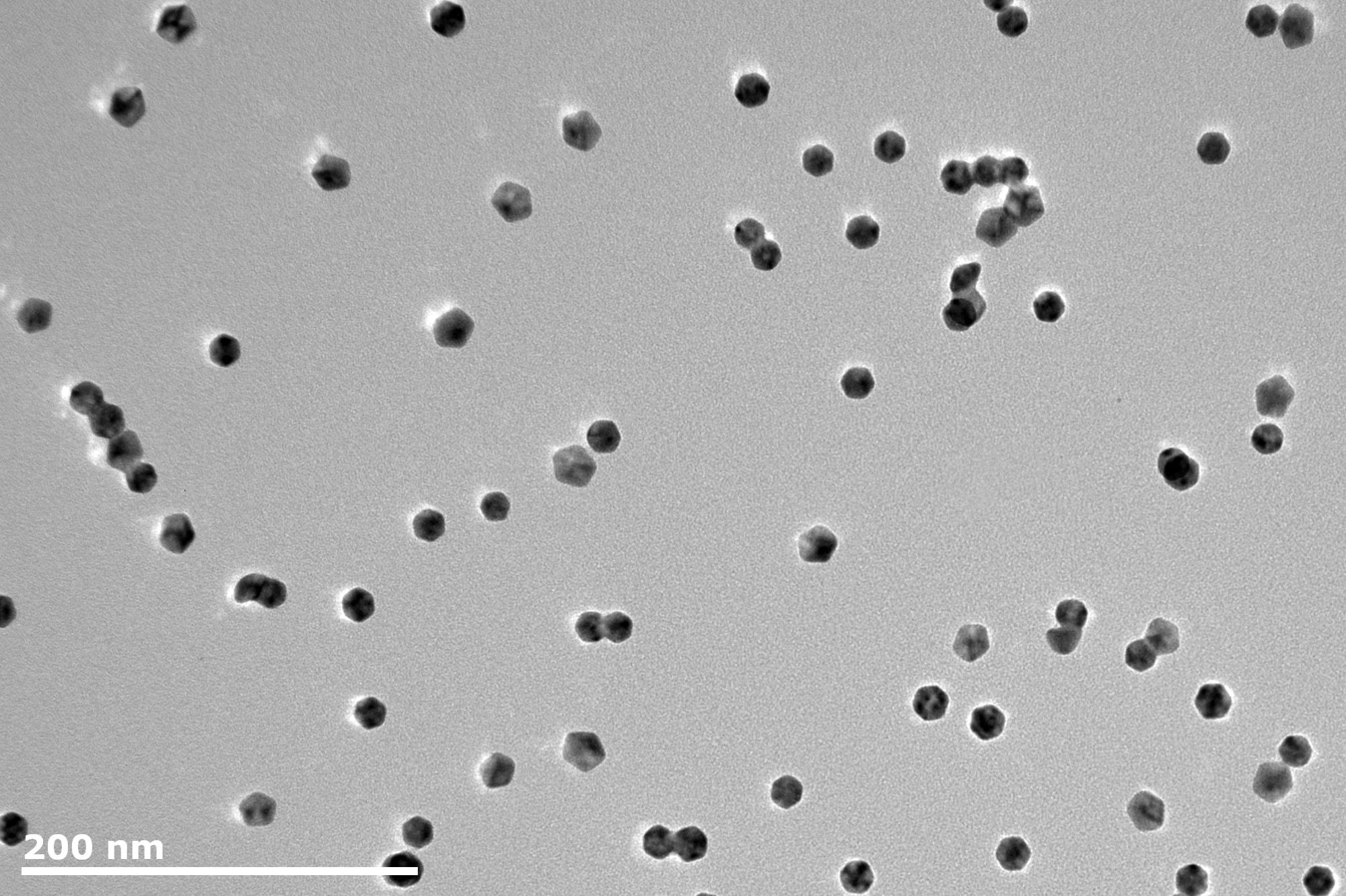

Image Credit: Nikalyte

If you want to deposit nanoparticles, all you do is open a door, put in your sample, close the door and press a few buttons, and you will have nanoparticles. I like to call it the ‘cup of coffee’ machine because you can put in your sample, go for a cup of coffee, and then come back, and your sample is ready!

We designed this instrument to be used by anyone in any research area. However, one of the things we were keen to accomplish was making it indestructible. It is hard to break anything on it, so it is ideal for teaching laboratories.

Can you imagine having a teaching laboratory where you could bring in doctoral students or postgraduate students? You could give them a project that included making a photonic sensor or a catalytic electrode. Could they make the whole thing just using our system? The NL50 makes this possible, and it is an excellent tool for anyone to use.

What are some of the NL50’s recommended applications?

We have almost 100 potential applications. In terms of nanostructured surfaces, they affect pretty much all areas of materials research. Anywhere you have an important surface, then we can have an impact. For example, you could combine graphene surfaces with nanoparticles where the nanoparticles act as a catalyst to perform chemistry that can then be processed by some graphene structure underneath that.

If you are looking at catalytic chemistry, you can form catalytic precious metal nanoparticles. One of the significant differences between a normal, plain electrode surface made out of platinum is if you coat that electrode with platinum nanoparticles, you can increase the surface area by about four orders of magnitude. For catalysts, it can make a big difference to the performance and cost.

Image Credit: Nikalyte

For a sensor such as an electrode, precisely the same thing applies. If you coat it with nanoparticles, you increase the surface area. With nanoparticles, when you get down to the nanoscale, you get all kinds of weird effects(i.e., quantum effects), which can be utilized. For instance, with optical spectroscopy, you can use the nanoscale ‘plasmonic’ effect to enhance spectroscopic signals by orders of magnitude.

We have also been doing a lot of work on antimicrobial and antiviral coatings. Nanoparticles can be very useful in terms of fighting microbes and viruses. Therefore, if you can disrupt those with nanoparticles, you can destroy the virus. Our materials have shown evidence that they are effective for those surfaces.

Can you tell us how you have managed to integrate over 20 years of experience into a compact instrument that is both simple to use and suited for researchers working in life sciences?

We are very familiar with the physics and mechanics behind the high-end nanomaterial production equipment since we designed it! We found where we have good windows of operation for lots of different materials, and we have locked down the parameters. As a result, we have made a simple system where we have left two or three simple parameters to vary, which will change the nanoparticles' properties, mainly the size of the nanoparticle that you can produce.

We have also simplified the mechanics to make it very easy to change the material you are looking at. We generate the material by the ‘magnetron sputtering’ process (a lump of metal that you put a plasma over, and the gas ions knock atoms from the metal). We then turn these into nanoparticles. Using a straightforward process to change the target, we can then quickly switch to generate nanoparticles from a different material.

In terms of the main drive behind the development of the NL50, can you tell us about your current role at the health sciences department at UHI?

I was lucky enough to be offered a role in Inverness, where we are building the Inverness Campus. We are building an elective care research hospital and a new university research building, which will be called the Life Sciences Innovation Centre.

There is an existing biomedical research department there, and I will set up a new medical nanotechnology group. I will be applying our techniques in making nanomaterials for life science applications.

One application uses nanostructured surfaces to determine how biological molecules bind to surfaces and how they behave. There are many unknowns in life sciences when you run the experiments, so we aim to bring certainty to some of the empirical aspects of life sciences research.

I will be looking at all kinds of things at Inverness, including making synthetic diamond surfaces, inorganic/ organic nanomaterials, and antimicrobial/antiviral surfaces. I will have a more complex version of the Nikalyte type system, and we will probably have a NL50 up in Inverness as well so that all the post-grads and post-docs can play around with NL50 system too.

The NL50 utilizes a technique called ‘gas terminated deposition.’ Can you expand on this and tell us more about this technique and the importance behind it?

We use a ‘Physical Vapor Deposition' (PVD) technique, which takes place in a vacuum. This is used throughout the world. Whenever anyone says to me, “It is fantastic what you are doing, but it can’t be scalable,” I always mention a packet of crisps – inside is a very thin film of aluminum, which has been coated by a PVD process. This shows that it is economical to do that.

Lifting the lid on the NL50

We are really at the cutting edge of PVD, and not many other people do this, which makes us quite unusual (e.g., using plasma to evaporate). Take aluminum: we would evaporate it and then hold the atoms in a chamber. Then, by controlling the pressure in that chamber and the throughput of gas through a little aperture at the end, we can essentially thermalize the atoms. When they have lost enough energy, they see another metal atom, and they start sticking together. Therefore, you begin to grow crystalline and 3D nanoparticles in real-time. It only takes about 1,000 nanoseconds to form a particle.

Our plasma sits at about 5,000 Kelvin, but by the time the nanoparticles hit a surface, they are thermalized, meaning no temperature is involved at the substrate.

Thus, we can coat a very sensitive substrate. However, a coating of atoms is extremely different from a coating of nanoparticles. For instance, a coating of gold done by PVD looks like gold. A coating of gold nanoparticles will either look grey or pink, depending on the nanoparticles' size and thickness, because you see nanoscale effects. You do not see bulk gold effects. It is an entirely different material.

How does the NL50 use this technique of gas terminated deposition differently to previous equipment? What sort of impact will this new development have on the industry and those that want to use this technique in particular?

In terms of what impact this will have on the industry, people in the research lab will really be able to investigate new materials and techniques that were probably unreachable previously.

One of the significant advantages we have is that you can go to one of the big chemical companies and buy nanoparticles, but they have been produced chemically and tend to come in a bottle in a solvent. There are some disadvantages there. One is that chemical nanoparticles tend to agglomerate together in the bottle, and on the surface, they are covered with various hydrocarbon impurities because of the chemical synthesis process.

One of our technique's advantages is that you can see completely separated, clean nanoparticles. That makes a massive difference in the reproducibility of your experiments. We will affect research groups in all kinds of industries, and the good thing is that if someone comes back to us and says, “We've had a big success, we really need to scale this up," then we have already been there. We know how to scale it up. We are working with companies who are producing nanomaterials at the ton scale. So, when the market is there, we know how to scale, and how we scale depends precisely on the product and the market that we are looking at.

During NL50’s development, what were some of the biggest obstacles you came across, and how were these overcome?

I have to say; I did not do all of the hard work developing this instrument. It was down to two of the guys, David, and Rao, who joined us and were doing all of the work. We had a meeting, and we sketched out the idea and what we might do. Then David and Rao translated that into a drawing for a prototype.

We had some engineering companies make the components, and we put it all together, and it worked. It was amazing. We were expecting several obstacles, but I got a phone call from Rao saying, "I switched to on," and he could see the nanoparticles depositing within a few seconds.

However, going from a prototype to our first demonstrator product was more challenging. This is because you must build all the electronics and the software, and there were some control issues there.

But, in terms of developing our first product, we have an NL50 on the shelf now ready to sell, and we are building up our next few products ready to sell, too. One of the significant obstacles we have now is that we believe one of the biggest markets for this instrument is in life sciences, and we are all physicists. We need to get into all the life science markets and conferences, which are virtual conferences these days, and that is an obstacle that we are looking at overcoming right now.

Looking towards the future, what would you say the potential of the NL50 is?

Looking to the future, what we will be doing is developing the instrument. We will be looking at more flexibility for different customers; we have had customers looking to coat powders or coat bigger substrates. Many people are looking to isolate nanoparticles, which we are immediately addressing. Still, the potential is great because I really would like to see this in teaching labs worldwide.

It gives students a direct way of generating nanosurfaces. If you look at nanosurfaces' potential in all different areas, it is fascinating for batteries, energy, or medicine. I took on the Inverness role because I have done a lot of work in physics and chemistry, but my next big challenge is medicine and life sciences. That is where I am excited about the potential for this.

We will be able to look at bio-applications such as the next generation of implants (i.e., how implants and bodies react together and how we get sensors onto implants). The main reason for us doing this is to make progress in this medical technology that can kill bugs and improve/save lives.

About Alistair Kean

Alistair is a Professor of Medical Nanotechnology at The University of the Highlands and Islands in Inverness, Scotland. He earned his Ph.D. in Physics at The University of St. Andrews in Scotland and was a Research Fellow at the Universities of Cambridge and Glasgow. He joined Sharp Laboratories of Europe in Oxford in 1992 before establishing an optoelectronics company, Kamelian Ltd, in 2000.

In 2004 he joined Mantis Deposition Ltd as Technical Director, where he developed an interest in nanotechnology. In 2013 he set up his own company, NikaWorks Ltd., which provides nanotechnology consultancy and contract coating services. He is also a consultant to Johnson Matthey PLC. In 2019 he co-founded Nikalyte Ltd., which produces a benchtop nanoparticle deposition system. Alistair also works with PolyCatUK Ltd and PinPoint Medical Ltd. on various healthcare projects. He was shortlisted as a cosmonaut in 1989 and likes to cook in his spare time.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.