Sponsored by InovensoReviewed by Louis CastelJan 18 2023

Flame retardants (FR) are a series of chemical compounds that are added to products and mixtures in order to inhibit or, as the name suggests, retard the ignition/burning of plastic. In the manufacture and development of such inhibitors, it becomes mandatory to design a thermally stable polymeric structure with a reduced probability of decomposing into combustible gases under heat – and, therefore, which can prevent or inhibit combustion.1

In the last decade, there has been an increasing and urgent need for researchers to investigate and develop enhanced ways to produce flame-retardant materials due to the significant increase in fires across many countries around the world.

Though fires have always existed, in recent years, outbreaks of fires have become more frequent - in part due to climate change. Fires hazards have become life-threatening events that can cause disfiguring burns and high rates of fatalities.

In 2018 alone, the National Fire Protection Association reported that there were 1.3 million recorded fire outbreaks in the US, which led to 3,120 civilian deaths, 15,200 civilian injuries, and approximately $11.6 billion in property damage. These numbers are still increasing and are becoming unacceptable. In order to tackle this challenge, key researchers within the field have used nanotechnology to create innovative and advanced flame-retardant solutions to fire risk.2

These investigations into new fire-retardant solutions have allowed researchers to make the most of existing material properties and discover new properties that can assist in the fight against fire, expanding the scope of application.

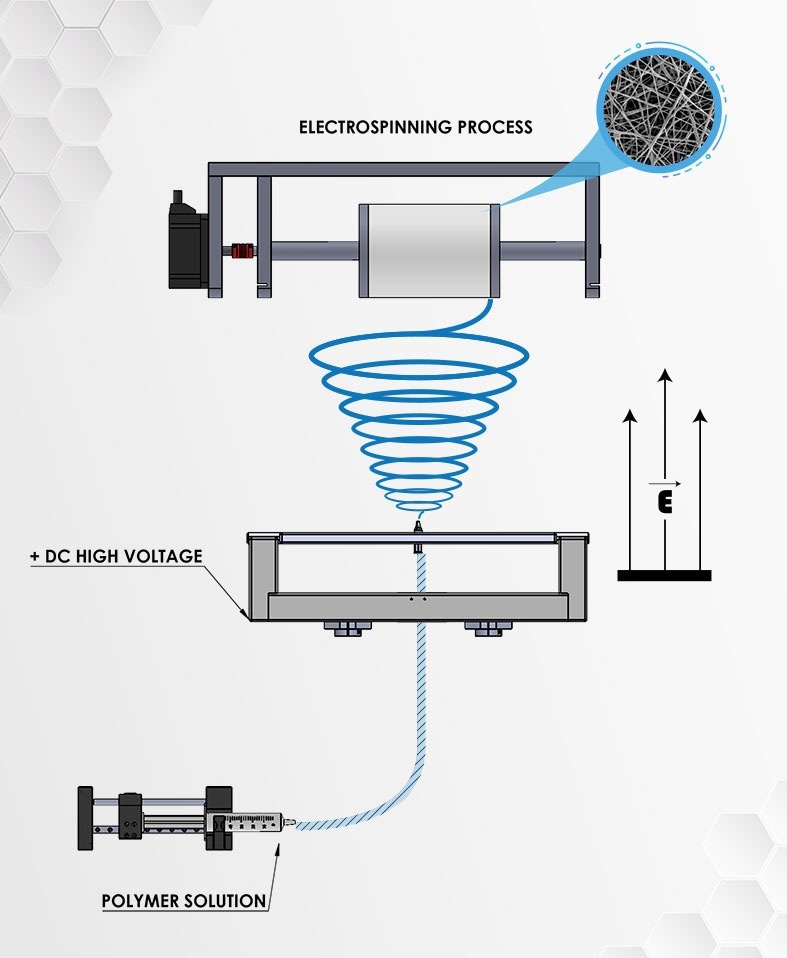

In contrast, micro-sized fibers (nanofibers that are obtained via electrospinning) are widely used thanks to their unique characteristics like selective permeability, large specific surface area, and strong surface adsorption properties.

These properties - and the fact that such nanofibers are lightweight - mean that they are in high demand around the world for various applications, including biomedical applications, packaging, energy, the automotive and food industries, and filtration.3

Despite this, the nanofibers’ thermal properties must be improved to maximize their use as fire retardant solutions. The most significant weakness of these nanofibers is that they do not have a strong resistance to heat and fire: at high temperatures, the mechanical properties of nanofibers may degenerate and release harmful substances during the combustion process, which naturally limits their use in such applications.

To overcome these obstacles, researchers have been exploring a number of options to generate flame-retardant nanofibers. Several recent studies have confirmed that electrospinning is an ideal and simple method when it comes to fabricating flame-retardant (FR) nanofibers.

To create FR nanofibers, researchers are able to incorporate FR additives, including chlorine, boric acid, bromine, phosphorus, and more, by adding them into the thermoplastic and thermoset polymeric solution.4-5

Image Credit: Inovenso

For instance, a recent study by Kim et al. explored the development of a multifunctional composite nanofiber: by incorporating tannin and reduced graphene oxide to polyurethane (PU), Kim et al. were able to improve the mechanical properties and flame retardancy of PU whilst showcasing their excellent antibacterial and electrospinning properties.

A new composite nanofiber was successfully generated and developed as a result of this improvement, highlighting various functionalities encompassed in a single material. The nanofibers identified and obtained by this process have potential applications as flame retardants, which can be used both within biomedical fields and protective clothing.6

Wu et al., 7 in a similar study, were able to manufacture an FR composite using polyamide 6 (PA6)/nanoclay/intumescent nanocomposite fibers through electrospinning.

The researchers claimed that high percentages of nano clay particles improved the electro-spinnability of the pristine nanofibers, and pristine nylon-6 samples have a higher degradation temperature than nanocomposite fibers. In addition, FR additives reduced the flammability of the nanofibers.

In another study, Xiao et al. developed polymer nanofibers with improved flame retardancy via coaxial electrospinning using graphene nanoplatelets hybridized with next-generation red phosphorus (NG-RP) and polyamide 66 (PA 66). The incorporation of NG-RP into PA66 improved the nanofibers’ flame retardancy and mechanical properties and maintained the brilliance and color of the produced nanofibers.8

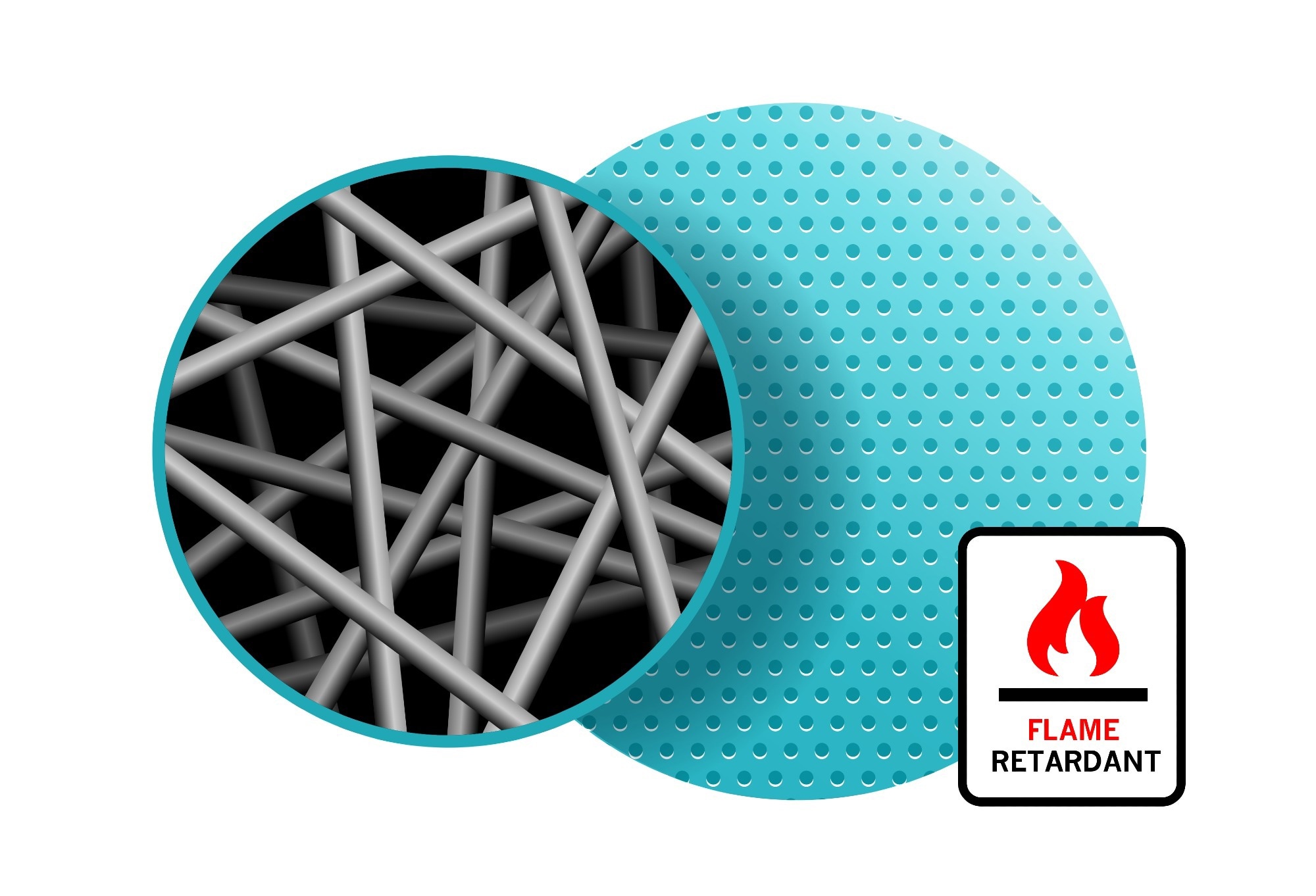

Image Credit: Inovenso

Yin et al. produced another example of FR nanofibers9. The team used electrospinning – specifically using multi-walled carbon nanotubes (MWCN), nanoclay particles, and FR additives – to develop nanofibers with enhanced FR characteristics.

Lower heat release and flame-retardant properties were boasted by the prepared FR/PA6 nanofibers. These properties can be attributed to the char residue, which acts as a protective thermal barrier.

In a similar study, Baddam et al. focused on generating novel superhydrophobic and flame-retardant nanofibers. These nanofibers were created through the process of electrospinning a polymeric solution made up of silicon dioxide (SiO2), boric acid (BA), and recycled expanded polystyrene (EPS).

The research team concluded that the best results were obtained by the incorporation of both SiO2 and BA inclusions in EPS: a total burning time of 25 seconds in the flammability test and a water contact angle of 156.98◦.

Therefore, the nanofibers obtained in this study hold the most potential for being used as a protective layer within the packaging and electronics industries.10

It is therefore demonstrated by the results above that the majority of these nanoparticles and FR additives can improve the flame-retardant properties and thermal stability of the textile polymers. The two main mechanisms behind these features are forming a protective barrier layer, which is joined with char promotion, and free radical trapping.11

It is important to note that some common FRs generate toxic compounds. Furthermore, there are a range of potential environmental and health concerns associated with the use of nanoparticles, which have received significant attention in recent years.

If such nanoparticles are to reach their full potential and become essential to flame-retardant solutions, a more detailed assessment of their possible environmental and health impacts is certainly needed. Researchers have used electrospinning to investigate non-toxic FR nanofibers, but this field still needs more attention.

The future applications of FR nanofibers include protective clothing, food packaging, householding and energy applications.

Although the industrial-scale production of FR nanofibers is still classed as a relatively new field, electrospinning has huge potential, especially considering that this technique has repeatedly proven its ability to be upscaled to larger production rates.

Image Credit: Inovenso

References

- Yan et al. Synthesis of organophosphate-functionalized graphene oxide for enhancing the flame retardancy and smoke suppression properties of transparent fire-retardant coatings, Polym. Degrad. Stab. (2020)

- “Fire Loss in the United States During 2018” – The National Fire Protection Association

- Satilmis et al. Development of superhydrophobic electrospun fibrous membrane of polymers of intrinsic microporosity (PIM-2) Eur. Polym. J. (2019).

- F.Z. Brahmia et al. Comparative study on fire retardancy of various wood species treated with PEG 400, phosphorus, and boron compounds for use in cement-bonded wood-based products, Surfaces and Interfaces (2020).

- S. Zhang et al. An inherently flame-retardant polyamide 6 containing a phosphorus group prepared by transesterification polymerization Polymer (Guildf) (2020)

- Kim et al. flame retardant, antimicrobial, and mechanical properties of multifunctional polyurethane nanofibers containing tannic acid-coated reduced graphene oxide, Polymer Testing, 2021

- Wu et al. Flame-retardant polyamide 6/nanoclay/intumescent nanocomposite fibers through electrospinning, Text. Res. J. (2014).

- Xiao, et al., Core-shell structured polyamide 66 nanofibers with enhanced flame retardancy, ACS Omega (2017).

- Yin et al. Flame-retardant polyamide 6/carbon nanotube nanofibers: Processing and characterization, J. Eng. Fiber. Fabr. (2015).

- Baddam et al. Fabrication of flame-retardant and superhydrophobic electrospun nanofibers, Surf. Interf. 2021

- Norouzi et al. Nanoparticles as Effective Flame Retardants for Natural and Synthetic Textile Polymers: Application, Mechanism, and Optimization, Polym. Rev. 2015

- www.inovenso.com

This information has been sourced, reviewed and adapted from materials provided by Inovenso.

For more information on this source, please visit Inovenso.