An international team of researchers from Stockholm University, the University of Illinois Chicago, and several partner institutions recently revealed a new class of materials in a study published in Science that could transform technologies that operate in harsh environments, such as the crushing pressure deep underground or the heat of a jet engine.

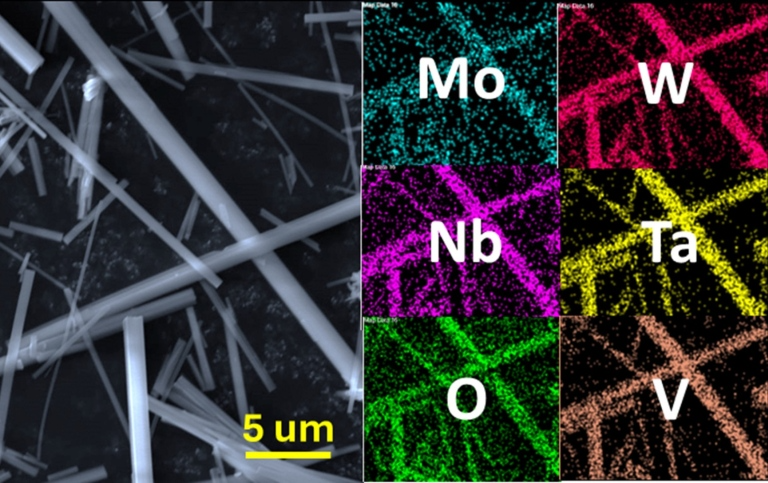

The 1D-HEO material (MoWNbTaV)O3. Image Credit: Hessam Shahbazi, University of Illinois Chicago.

The 1D-HEO material (MoWNbTaV)O3. Image Credit: Hessam Shahbazi, University of Illinois Chicago.

The new material discovered by the researchers is a one-dimensional high-entropy oxide nanoribbon (1D-HEO), which is made up of a complicated mixture of five metal elements that are bound together with oxygen: molybdenum, tungsten, niobium, tantalum, and vanadium.

This is a high-entropy material, not your typical ceramic or alloy, created by combining numerous elements in nearly equal proportions to use structural chaos as a stabilizing factor rather than a defect.

Shock-Resistant Coatings for Space Missions

According to Zhehao Huang, the shape and structure of the material are what distinguish it, rather than its content. He is the primary researcher for this project at Stockholm University's Department of Chemistry.

Remarkably resistant to heat (up to 1000 °C), pressure (up to 30 gigapascals), and chemical corrosion (surviving strong acids and bases for a week), the nanoribbons are thousands of times thinner than a human hair. Most remarkably, they are superior to all existing aerospace alloys in their ability to absorb mechanical energy, making them perfect for shock-resistant coatings or space mission structural components.

“Cutting-Edge Electron Microscopy Techniques”

Behind our results lie cutting-edge electron microscopy techniques, particularly Transmission Electron Microscopy, TEM, and Three-Dimensional Electron Diffraction, 3DED, which have become indispensable tools in modern materials science.

Zhehao Huang, Department of Chemistry, Stockholm University

Ultra-high-resolution images obtained using TEM confirmed the nanoribbons’ smooth, defect-free surfaces and consistent interior structure. These atomic-level images were critical in determining whether the material remained intact even after exposure to severe temperatures and corrosive conditions.

Three-Dimensional Atomic Structure of Nanoribbons

Even more important was the application of 3DED, which allowed for the reconstruction of these nanoribbons' entire three-dimensional atomic structure.

Huang added, “With 3DED, we can determine the atomic arrangement from crystals that are only tens of nanometers in size–something traditional X-ray diffraction simply can’t handle.”

This approach revealed the structure's precise arrangement of metal and oxygen atoms.

“It allowed us to detect subtle features like oxygen vacancies and the presence of mixed metal coordination environments, which are crucial for understanding the material’s remarkable stability under extreme conditions,” added Zheho Huang.

These findings were more than just confirmed; they were fundamental. Without them, the nanoribbons' amazing tenacity would have remained a mystery, stated Zhehao Huang.

Possible to Design Resilient Materials

The potential uses of these findings are enormous, according to the researchers, ranging from electronics that can tolerate Venus-like heat to spaceship materials that can withstand vacuum and vibration. Furthermore, the study provides a roadmap for developing low-dimensional, resilient materials by using entropy as a stabilizing feature rather than as a challenge.

“Beyond the material itself, the research sets a benchmark for how nanostructures are studied. By combining TEM and 3DED, scientists can now uncover the atomic details of materials that are too small or too complex for traditional techniques. It’s a powerful reminder that in science, how we observe can be just as critical as what we observe,” concluded Zhehao Huang.

Journal Reference:

Shahbazi, H., et al. (2025) Resiliency, morphology, and entropic transformations in high-entropy oxide nanoribbons. Science. doi.org/10.1126/science.adr5604