Photosensitive polymer films are commonly utilized as a dielectric layer in microelectronics packaging.

The performance of the organic film is determined by the adhesion quality between the polymer and the underlying passivation layer, which is influenced by the high temperatures and humidity that devices are exposed to on a daily basis.

Nanoindentation-based adhesion testing has historically been performed after simulated environmental exposure (ex-situ) to simulate the effects of realistic settings. However, there are substantial advantages to performing in-situ nano-indentation-based adhesion testing, which captures both reversible and permanent impacts in real time.

This article employs a Hysitron TI 980 TriboIndenter® with the xSol® Humidity module to provide direct, in-situ mechanical characterization of a nitride/polymer interface at controlled temperatures and relative humidity. Relying solely on ex-situ tests after aging can result in an overestimation of interface reliability.

Environment-Driven Adhesion Degradation

Photosensitive polymeric dielectrics of micrometric thickness are widely used in microelectronic devices with non-hermetic packaging.

These organic films are typically placed between traditional inorganic passivation layers and the exterior encapsulating material (for example, epoxy molding compound) to provide mechanical protection, electrical insulation, and an extra barrier against moisture entry into the active device.

As a result, the organic insulator's performance is significantly dependent on the polymer's adhesion to the underlying inorganic passivation. These interfaces frequently encounter adverse environmental conditions, such as high temperatures and humidity, which can reduce adhesion and jeopardize device reliability.

Traditional adhesion testing methods use ex-situ nanoindentation following environmental aging treatments. However, this method may not adequately reflect the interface's real-time mechanical behavior under operational conditions, as post-aging recovery events may obscure the true level of degradation.

This article compares in-situ nanoindentation-based adhesion testing to standard ex-situ testing for a photosensitive polybenzoxazole (PBO) layer produced on silicon nitride (SiN).

Experimental Setup

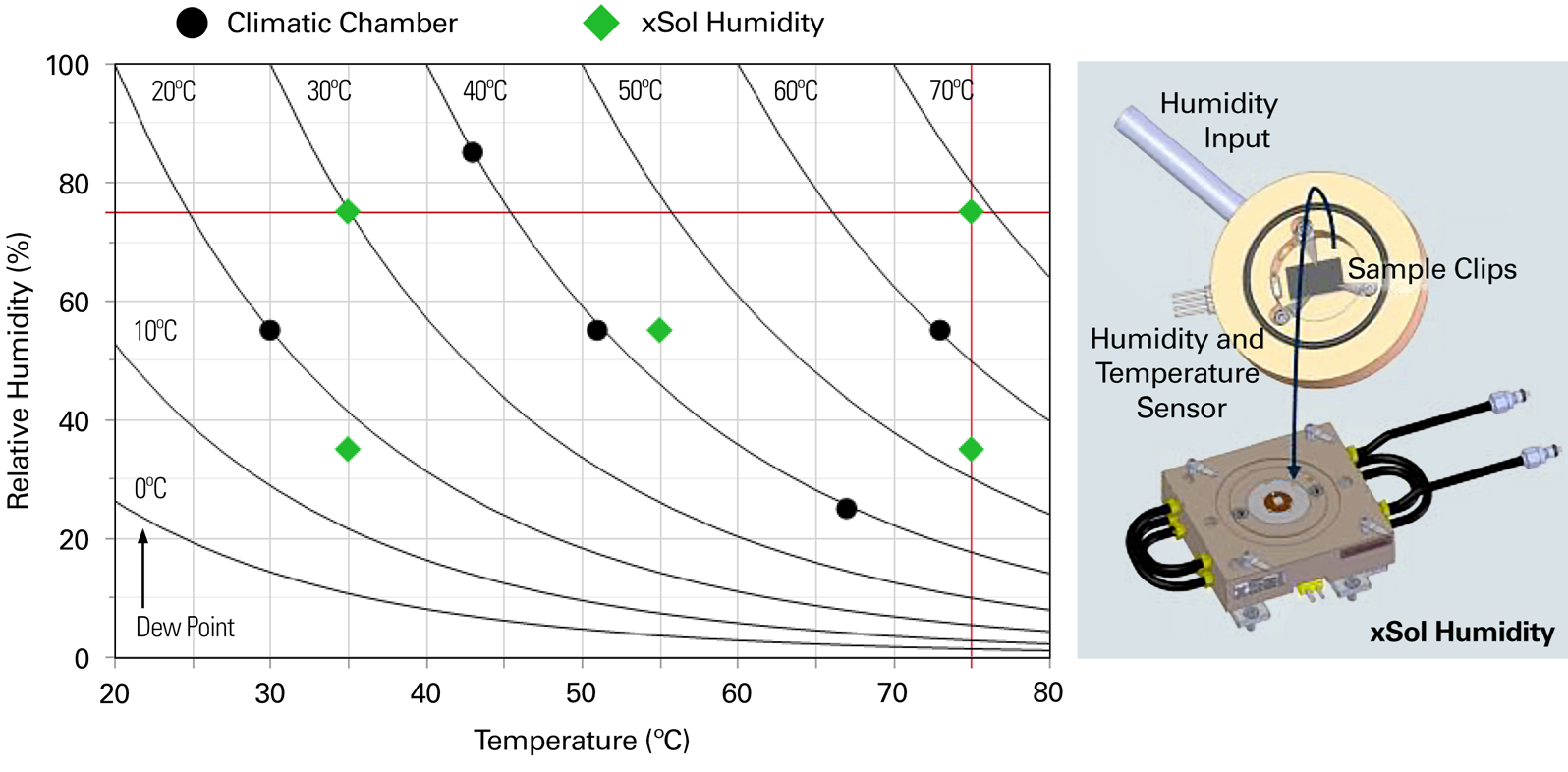

Two types of SiN substrates were studied: normal stoichiometric SiN (Si/N 0.8 at%) and Si-rich SiN (Si/N 1.1 at%). Both were covered with a 9 μm PBO film deposited using electrospinning. The samples were submitted to ex-situ and in-situ adhesion testing using nanoindentation under various environmental conditions, as shown in Figure 1.

Figure 1. T-RH plot showing the lines of constant dew point and the points characterized in this study by the climatic chamber or the xSol Humidity module. Red lines indicate the operational limit of the humidity module. Image Credit: Bruker Nano Surfaces and Metrology

In-Situ Testing Results

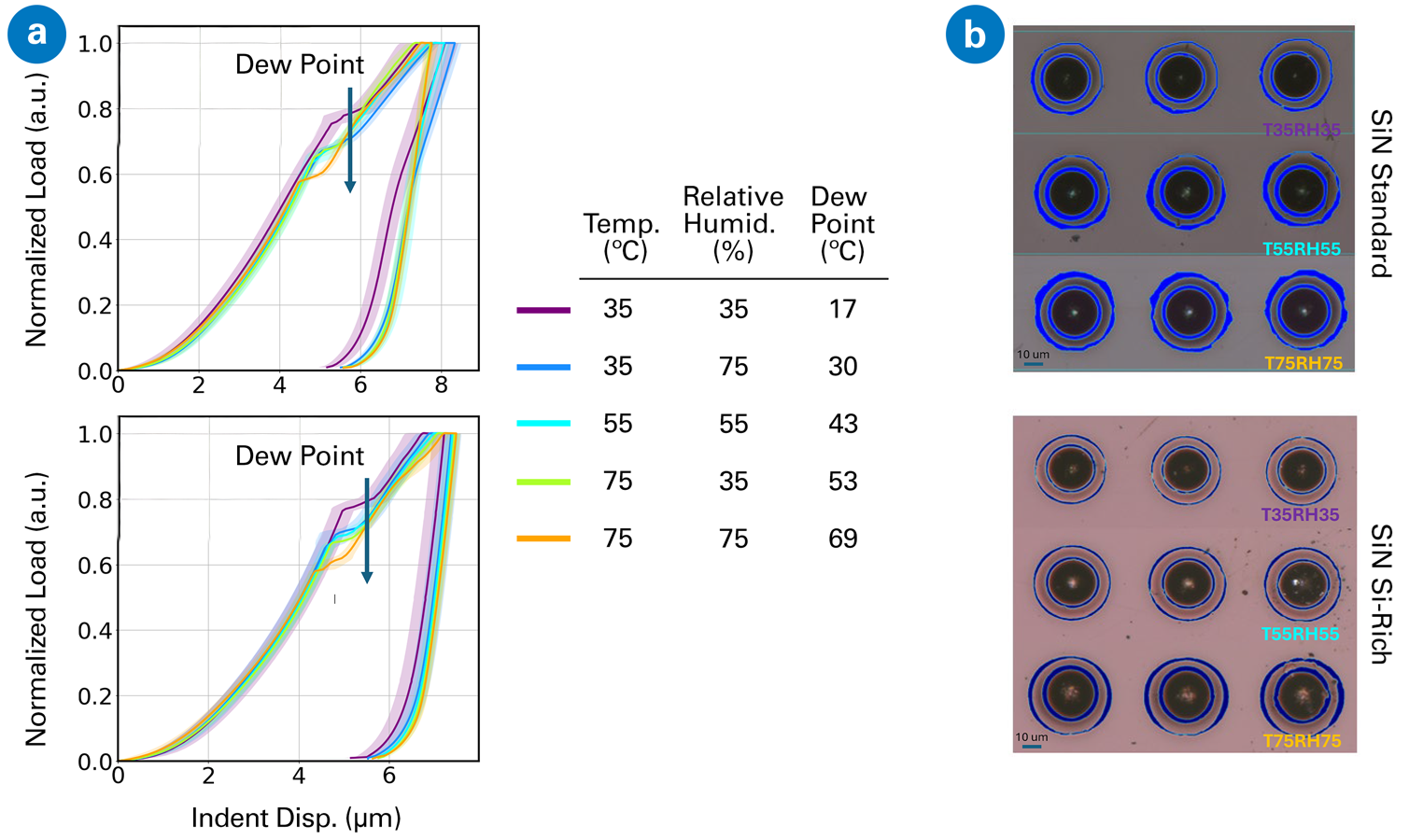

In-situ nanoindentation experiments with the xSol Humidity module demonstrated a noticeable drop in adhesion strength with rising dew point, as shown in Figure 2.

The critical delamination load, as measured by a discernible local slope decay in the load-displacement curve, decreased consistently as the dew point increased for both standard and silicon-rich SiN substrates (Figure 2a).

The delaminated area increased with the ambient dew point, as shown by optical micrographs of residual indents (Figure 2b). Brightness thresholding was used to segment the outer ring of delamination, which appears as a zone with higher contrast.

These findings indicate that moisture uptake by the PBO coating, as well as the resulting swelling and interfacial weakening, is strongly proportional to the ambient moisture dew point.

Figure 2. (a) Load-displacement curves for the two samples subjected to five different environments. A decay event is indicated by a sudden change in the slope of the curve. (b) Post-indentation footprints in three selected environments. The dependence of PBO adhesion on the dew point of the environment can be seen from the decrease in the critical delamination loads and the increase in the delaminated area. Image Credit: Bruker Nano Surfaces and Metrology

The mechanical compliance of the PBO remained rather consistent across all tested settings, indicating that the observed changes in critical load were mostly due to variations in interfacial adhesion rather than bulk polymer characteristics.

Notably, despite differences in SiN stoichiometry, PBO and both samples showed identical adhesion degradation vs dew point profiles, indicating that environmental circumstances are the most important factor driving adhesion loss.

Comparison with Ex-Situ Testing

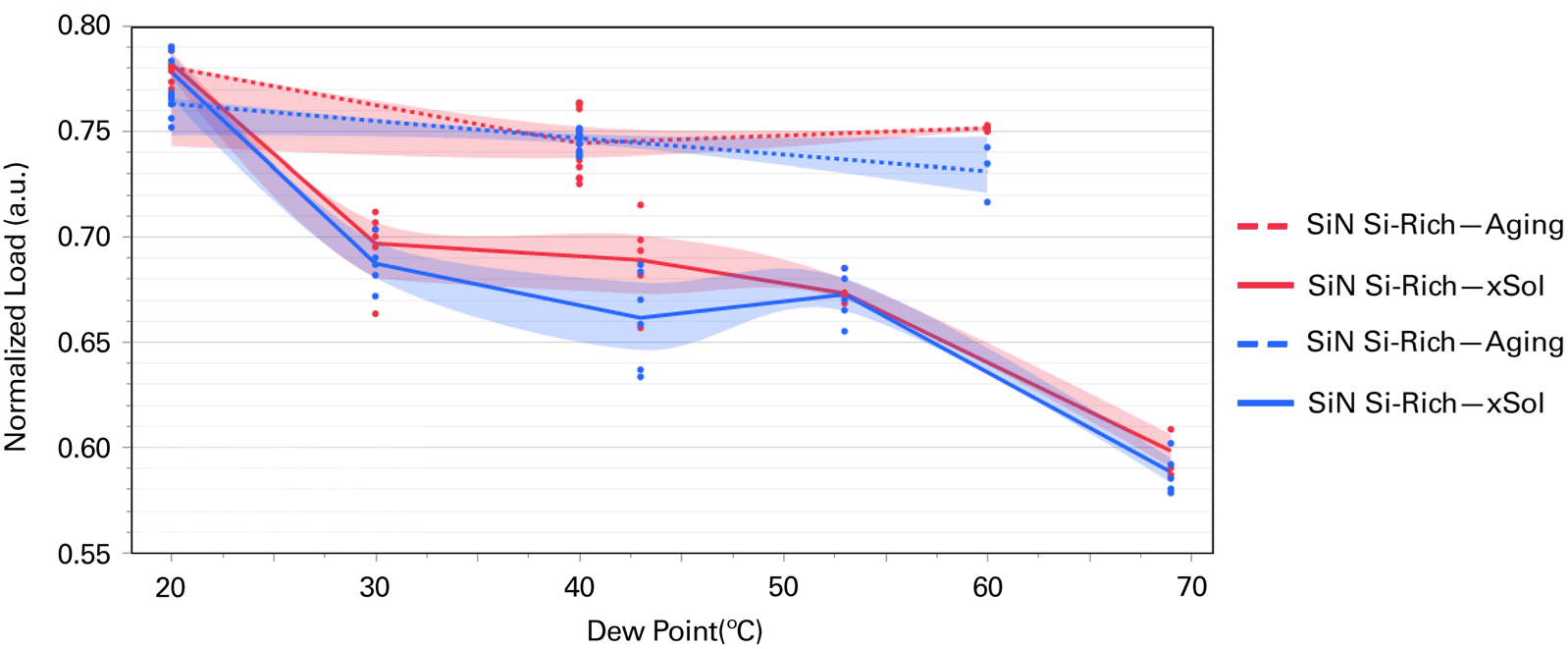

Complementary ex-situ tests were performed on identical materials after aging in a climatic chamber at increased temperatures and humidity for two and seven days. After aging, the samples were removed and examined in an ambient laboratory environment.

Figure 3 shows that the adhesion behavior differed significantly from that seen in-situ. After two days of aging (not reported), the critical delamination load values had mostly recovered to levels similar to the initial ambient readings.

Even after seven days of aging (Figure 3, dashed lines), only a minor permanent adhesion loss was seen, with no evident relationship to the severity of the aging environment.

Figure 3. The critical load of delamination, and thus PBO adhesion, decreases as the dew point increases. This trend is hardly visible in the samples subjected to aging, due to probable recovery of PBO`s adhesive properties, while in-situ tests show a more distinct trend. Image Credit: Bruker Nano Surfaces and Metrology

When compared to in-situ data (Figure 3, solid lines), ex-situ testing underestimates the level of adhesion breakdown that occurs following exposure to extreme circumstances.

This shows that aging (defined as a permanent change in physical attributes) is not the main source of adhesion loss and that the current moisture level significantly impacts decreasing (reversibly) interfacial strength, which can rebound. The regained strength is most likely due to moisture's quick desorption upon return to ambient conditions.

xSol Humidity Enables Realistic Evaluations of Adhesion Performance

Bruker's xSol Humidity module allows for real-time measurements under regulated temperature and humidity, indicating that current exposure to a particular moisture level causes greater SiN/PBO adhesion degradation than aging in comparable severe conditions.

Rapid moisture desorption may cause PBO adhesion to recover partially or completely. When only ex-situ tests after aging are used, the interface dependability may be overestimated.

The comparison of in-situ and ex-situ adhesion tests demonstrates the importance of recovery time in appropriately determining the interfacial dependability of photosensitive insulators at passivation layer interfaces.

In-situ nanoindentation with environmental control offers a more realistic and thorough assessment of adhesion performance, accounting for reversible and permanent impacts caused by key conditions. This method is critical for creating and validating strong polymer/inorganic interfaces in microelectronic devices.

Acknowledgments

This article has been produced using materials written by Eric Hintsala, Ph.D., NI Applications Development Manager, Bruker; Filippo Sabatini, Ph.D. candidate, Politecnico di Milano and STMicroelectronics; Emanuele Cattarinuzzi, Ph.D., Characterization and Modeling Engineer, STMicroelectronics; Vincent Coutellier, Characterization and Modeling Engineer, STMicroelectronics

This information has been sourced, reviewed and adapted from materials provided by Bruker Nano Surfaces and Metrology.

For more information on this source, please visit Bruker Nano Surfaces and Metrology.