What started as a seed of an idea discussed between two friends has this year borne fruit. Published in Advanced Functional Materials in the summer, the Greco team sat down with AZoNano to discuss their research.

The group has developed a way to turn waste material into a flexible, biodegradable sensor.

From hand-crushing almond shells with a hammer to a laser-induced graphene sensor, this interview is a behind-the-scenes look at the study.

Talk us through the ideas behind the study - how did you end up landing on almond shells, for instance?

We knew that lignin is a good precursor for Laser-Induced Graphene, and this has been known in the literature for some time. So, we considered that lignin-rich materials could be potentially useful for this purpose. But actually, the real and concrete inspiration to use almond shells came from outside the lab.

In fact, it came from a conversation between Francesco Greco (one of the authors and the head of the LAMPSE lab) and his best friend Giuseppe, who was working at the company Damiano Organic at the time.

Some years ago, while discussing his job at Damiano, Giuseppe complained to Francesco about the huge quantity of shells produced during nut processing and how this waste was more of a burden than a resource. Giuseppe’s words sparked the first idea of using almond shells. Sadly, Giuseppe died shortly after. This project is dedicated to his memory, and his fundamental contribution is acknowledged in the paper.

Read the details of the study here

Why is biodegradability important for electronic sensors?

In recent years, there has been a growing interest in developing sustainable and degradable materials for electronics, driven by the need to reduce environmental impact and create innovative technologies that can replace traditional, non-degradable materials.

Biodegradability is especially important for electronic sensors because of the increasing issue of electronic waste (e-waste), now considered one of the fastest-growing categories of waste worldwide.

Once used or broken, electronic devices are often replaced with new ones instead of being repaired. No longer useful, the old devices are discarded and end up in landfills, where recycling options are limited.

Electronics are typically made from materials that do not decompose naturally, so they can remain in soil or water for decades. Whilst buried amongst rubbish, these materials can pollute ecosystems, release toxic compounds, or break down into microplastics.

As a result, even sensors that were originally designed to protect and study the environment can ironically become a source of contamination themselves.

Biodegradable materials are one route to change; they reduce the burden of e-waste. Additionally, there is an increasing need for “transient” electronics and sensors: devices that have a limited lifetime (ranging from a few days to a few months), which can then degrade without leaving harmful residuals.

Such sensors can find applications in agriculture, environmental monitoring, or wearable electronics. These temporary devices can be programmed to function only as long as needed and then naturally degrade.

This reduces the costs of collection and disposal while minimizing the environmental footprint. This approach is crucial in the context of sustainable development, the circular economy, and broader efforts to mitigate pollution and reduce reliance on non-renewable sources.

Why have you focused on sustainable graphene?

The materials commonly used in electronics, such as metals and graphene, have a high environmental footprint and are usually obtained from energy-intensive methods.

Our collaboration with the Italian company Damiano Organics (a global leader in the production and transformation of organic dried fruit like almonds and hazelnuts, among others) gave us access to agricultural waste (almond shells).

This biomass is rich in lignin and cellulose, molecules that can be converted into graphene through a laser process, resulting in laser-induced graphene.

It is also important to say that the laser scribing process does not require the use of any chemicals and allows for localized carbonization, making it scalable and adaptable to a wide range of precursors.

This approach enabled us to upcycle biowaste into highly efficient precursors for LIG, addressing the e-waste problem and converting biowaste with no commercial value into a valuable resource.

Having developed this sustainable graphene, we are now working to create temporary, degradable electronic devices that will prevent the formation of microplastics and e-waste, reducing their impact on the environment.

How did you assess the biodegradability of the graphene to evaluate its environmental footprint?

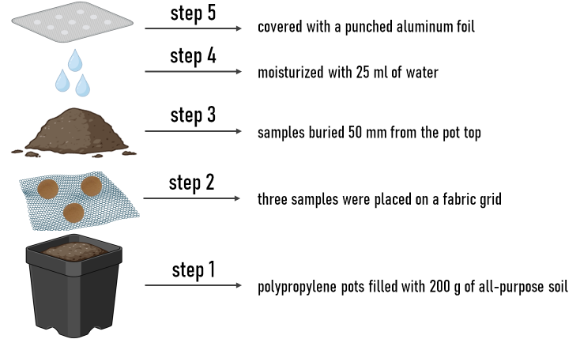

To assess the degradability of our samples, we monitored their mass change over time while immersed in soil. This approach is a simple yet effective way to assess material degradation under natural conditions.

In our method, we used five pots containing soil. Three 2 cm diameter samples were placed in each pot (to calculate the average mass loss and standard deviation for each pot). Samples were removed after varying periods of time: from the first pot, samples were removed and mass loss was measured after two days, then after eight days, 20 days, 40 days, and 90 days.

The initial mass loss was primarily due to the dissolution and breakdown of the chitosan matrix, which is more sensitive to moisture and environmental factors. As degradation progressed, the remaining structure became more rigid and brittle, eventually disintegrating into small fragments.

By monitoring these changes over 90 days, we observed a mass reduction of over 60 %, confirming the high degree of biodegradability of the composite in soil.

Image Credit: Yulia Steksova/LAMPSe

How do you envision your findings being applied outside of the lab?

There is a wide range of potential applications for the resulting materials, including wearable electronics or in agriculture and environmental monitoring, such as humidity sensors, air quality sensors, water content sensors, and potentially soil monitoring.

Because of their biodegradability, laser-induced graphene-based sensors don't need to be collected after their useful life, which makes them particularly appealing in these contexts.

It's worth noting that the almond shell-based composites themselves could be of interest to the eco-design and packaging industries; smart packaging is possible, since the composite is quite flexible.

Of course, I'm hoping for an integrative approach - combining it with other biodegradable materials and minimizing energy consumption during production (optimizing the synthesis and laser processing methods) to scale it up for commercial use. We also hope that this method will stimulate other researchers to focus on fully biobased and degradable materials.

Tell us something unexpected that came up whilst conducting the research. What did you find that you couldn't have predicted?

I think the most interesting and unexpected part of this study was identifying a strong dependence of graphene morphology and quality on the type of laser used for carbonization and on the laser scribing parameters employed.

A subsequent comprehensive study of the laser-induced graphene structure, conducted jointly with the Graz University of Technology (TU Graz) using MicroCT (a 3D imaging technique) and scanning electron microscopy, revealed significant differences in the morphology and quality of the laser-induced graphene.

About the Greco Group

Image Credit: Francesco Greco/LAMPSE

We investigate soft, stretchable, conformable, and conductive materials with primary applications as sensors/actuators in biomedicine and robotics. We process these materials and fabricate devices using several techniques, like ink-jet printing, screen printing, spin coating, and laser-induced pyrolysis. Our goal is to develop sustainable materials and processes for next-generation devices.

The co-authors of the study are: Yulia Steksova, PhD student; Anna Chiara Bressi and Marina Galliani, Postdoctoral Researchers; Hilda Gomez Bernal, Technician; and Francesco Greco, Associate Professor.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.