The iX05 is an operando nanoindenter. It is intended to test local mechanical characteristics in real-world settings such as high and low temperatures, high strain rates, and liquid environments.

Traditional nanoindenters are designed to test materials in laboratory settings. However, in real applications, materials are frequently exposed to severe conditions, which have a significant impact on their mechanical behavior. The iX05 is designed to evaluate materials in conditions similar to their intended use.

The iX05 combines MEMS-based technology's high resolution and speed with quick control electronics and environmental management, making it the ideal instrument for measuring and visualizing the mechanical characteristics of materials under various testing conditions.

Key Features

Operando Nanoindentation

Image Credit: Oxford Instruments

The iX05 operando nanoindentation device can test at high temperatures up to +800 °C and cryogenic temperatures down to -150 °C. It has a motorized chamber with environmental control for testing in an inert gas atmosphere or high vacuum, which reduces oxidation and contamination.

- Temperature range: –150 °C to +800 °C

- Operating pressure: down to 5⋅× 10–4 mBar

Ultra-Fast Nanoindentation

Image Credit: Oxford Instruments

The iX05 features ultra-fast nanoindentation capabilities, capable of up to 30 indentations per second. It provides unrivaled performance at high speeds by integrating the MEMS force sensors with ultra-fast electronics, resulting in a sampling rate of 2 MHz and a feedback frequency of 500 kHz.

- Temperature range: up to 2 N

- Force noise floor (at 10 Hz): down to 100 pn

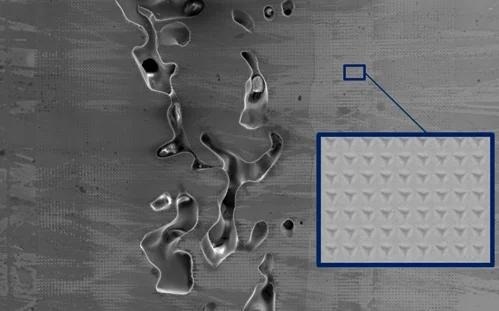

Ultra-High Resolution

Image Credit: Oxford Instruments

The iX05 has ultra-high resolution nanoindentation capabilities that can detect even the slightest differences in hardness and elastic modulus. It has displacement sensing with a noise level of less than 5 pm over a 20 μm range, spanning seven orders of magnitude.

The instrument also features interchangeable MEMS-based force sensors for SI-traceable force metrology, with a range of 100 pN (noise floor) to 2 N, or ten orders of magnitude. To ensure accuracy and precision, the iX05 features automated, high-precision calibration methods that enable smooth operation.

Accessories

High-Temperature Module

Image Credit: Oxford Instruments

The High Temperature Module can heat specimens to a maximum temperature of 800 °C.

When combined with the Microforce Sensing Probes with Active Tip Heating, it simplifies isothermal nanomechanical testing of samples at varied temperatures. By performing tests in high vacuum, the oxygen concentration can be reduced by a factor of one million compared to systems that employ inert gas to prevent unwanted oxidation.

Specifications

Source: Oxford Instruments

| |

Temperature range |

Oxidation prevention |

| High-Temperature Module |

800 °C |

Vacuum |

Cryogenic Testing Module

Image Credit: Oxford Instruments

The Cryogenic Temperature Module utilizes liquid nitrogen as a chilling agent to achieve temperatures as low as –150 °C, enabling experiments to be conducted at extremely low temperatures. The iX05 effectively minimizes condensation-related concerns by operating under high vacuum levels, enabling smooth and dependable cryogenic testing.

Specifications

Source: Oxford Instruments

| |

Temperature range |

Condensation prevention |

| Cryogenic Module |

-150 °C |

Vacuum |

Scratch Testing Module

Image Credit: Oxford Instruments

The combination of an exchangeable sample stage, a piezoscanner, and a 2-Axis Microforce Sensing Probe enables advanced techniques such as nano-scratch and nano-wear testing, as well as SPM imaging, by allowing the sample to move in-plane while applying a normal force.

Specifications

Source: Oxford Instruments

| |

Travel range |

Noise floor |

| Piezo-Scanner |

200 µm |

0.4 nm |

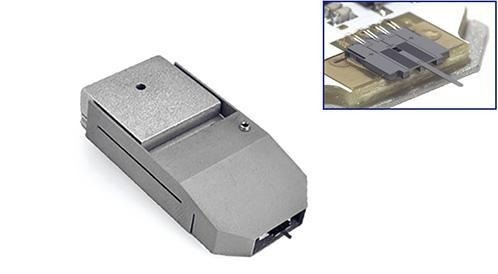

Ultra-Fast Mapping Module

Image Credit: Oxford Instruments

The ultra-fast mapping module increases indentation speed from 3 to 30 indents per second, enabling the creation of high-resolution maps with over 90,000 indents in under an hour. The unique sample stage is critical for fast acceleration, stopping, stabilization, measurement of nanoindentation, and then acceleration to the next indent point in under 33 milliseconds, all while preserving outstanding precision.

Specifications

Source: Oxford Instruments

| |

Indentation speed |

| Ultra-Fast Mapping Module |

30 Indents/s |

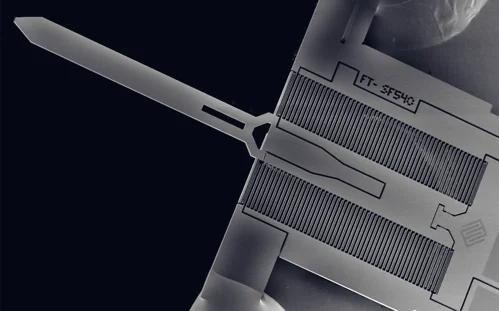

Microforce Sensing Probes

Image Credit: Oxford Instruments

The FT-X Microforce Sensing Probes are sensors that can measure forces ranging from sub-nanonewtons to two newtons along their probe axis. They are available in a broad range of tip materials and shapes, including diamond Berkovich, cube corner, flat punch, wedge, conical, and others.

Specifications

Source: Oxford Instruments

| |

Range |

Noise Floor (10 Hz) |

| S200 |

+/- 200 μN |

0.1 nN |

| S2’000 |

+/- 2’000 μN |

0.5 nN |

| S20’000 |

+/- 20’000 μN |

5 nN |

| S200’000 |

+/- 200’000 μN |

50 nN |

| S2’000’000 |

+/- 2’000’000 μN |

500 nN |

Two-Axis Microforce Sensing Probes

Image Credit: Oxford Instruments

Microforce Sensing Probes are multi-axis force sensors based on Micro-Electro Mechanical Systems (MEMS) that can measure forces in two in-plane directions at the same time. These sensors' principal applications include nano-scratch, nano-tribology, and nano-wear testing.

Specifications

Source: Oxford Instruments

| |

Range |

Noise Floor (10 Hz) |

| Normal |

+/- 20’000 μN |

10 nN |

| Tangential |

+/- 20’000 μN |

10 nN |

High-Temperature Microforce Sensing Probes

Image Credit: Oxford Instruments

High-Temperature Microforce Sensing Probes are MEMS-based sensors that can measure forces ranging from 200 mN to 2 µN. Furthermore, with the monolithically integrated tip heater, the temperature of the nanoindenter tip can be precisely matched to that of the sample, allowing for isothermal testing conditions.

Specifications

Source: Oxford Instruments

| |

Force range |

Force resolution (noise at 10 Hz) |

| FT-S200'000-HT |

+/- 200 mN |

100 nN |