The i04 Femto-Indenter represents a cutting-edge nanomechanical testing system that excels in precisely measuring the mechanical and tribological characteristics of materials at both micro- and nanoscale levels.

Being the first MEMS-based nanoindenter globally, the i04 employs FemtoTools' proprietary Micro-Electro-Mechanical System (MEMS) technology. Drawing on more than 20 years of advancements, this nanoindenter delivers unparalleled resolution, consistency, and dynamic stability.

The i04 Femto-Indenter has been specifically designed for the mechanical evaluation of metals, ceramics, thin films, and coatings, as well as more flexible microstructures such as metamaterials.

Typical applications encompass the measurement of hardness and elastic modulus, mapping of mechanical properties, and supplementary modules for scratch testing, SPM imaging, and high-temperature assessments.

Key Features

Unmatched Dynamic Range

Image Credit: Oxford Instruments Materials Science

Micro-Electro-Mechanical System (MEMS)-based force sensors exhibit an unparalleled dynamic range of up to 100 kHz, attributed to their remarkably small mobile mass and elevated stiffness. The precise fabrication tolerances of MEMS result in the lowest achievable noise floor, which can reach as low as 500 pN.

Resonance frequency: Up to 100 kHz

Force noise floor: Down to 500 pN

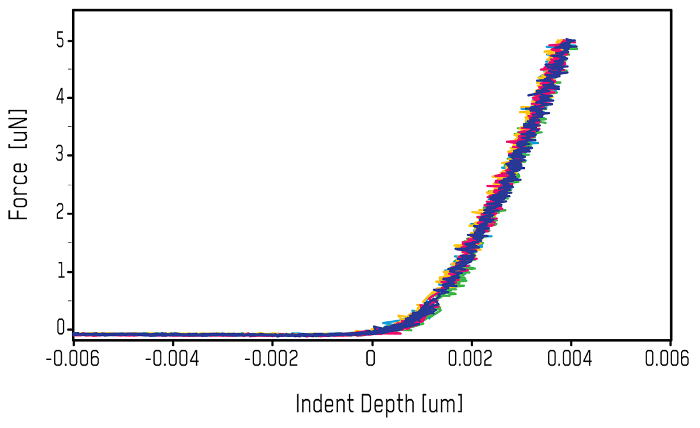

Highest Resolution

Image Credit: Oxford Instruments Materials Science

A crucial quality metric for a nanoindenter is its capacity to precisely measure indentation depth. This capability is constrained by the noise floor (resolution) of the displacement sensor. With an unparalleled noise floor of <50 pm, the i04 Femto-Indenter delivers outstanding results even at the most minimal depths, as demonstrated here with consistent indentation curves down to just 5 nm on quartz glass.

Displacement noise floor: <50 pm

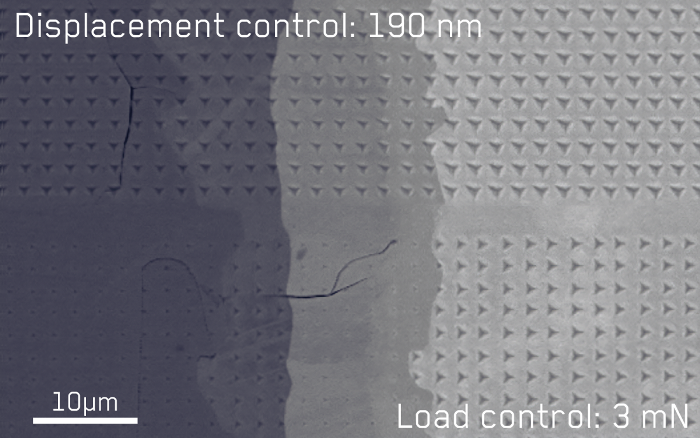

True Displacement Control

Image Credit: Oxford Instruments Materials Science

Displacement-controlled nanoindentation is crucial for assessing and contrasting mechanical properties at uniform indentation depths, guaranteeing the examination of comparable material volumes.

Control mode: Native displacement control

Accessories

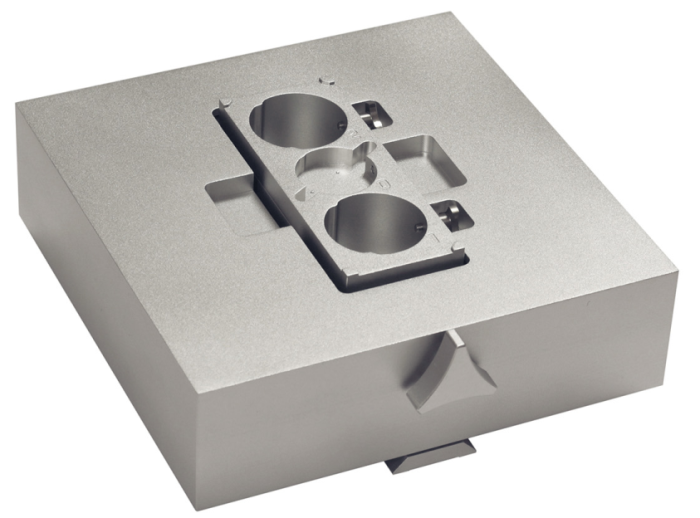

High-Temperature Module

Image Credit: Oxford Instruments Materials Science

The high-temperature module facilitates mechanical testing, including nanoindentation, at regulated temperatures reaching up to 400 °C within an inert gas environment. When paired with Oxford Instruments’ microforce sensing probes that include tip heating, it allows for controlled isotherm testing.

Specifications

Source: Oxford Instruments Materials Science

|

Temperature range |

Oxidation prevention |

| High-Temperature Module |

400 °C |

Inert gas flooding |

Scratch Testing Module

Image Credit: Oxford Instruments Materials Science

The integration of an exchangeable sample stage with a piezoscanner and a FemtoTools 2-Axis Microforce Sensing Probe enables the implementation of advanced methodologies, including nano-scratch and nano-wear testing, as well as SPM imaging, by allowing for in-plane movement of the sample while concurrently applying a normal force.

Specifications

Source: Oxford Instruments Materials Science

|

Travel range |

Noise floor |

| Piezo-Scanner |

250 µm |

0.4 nm |

Microforce Sensing Probes

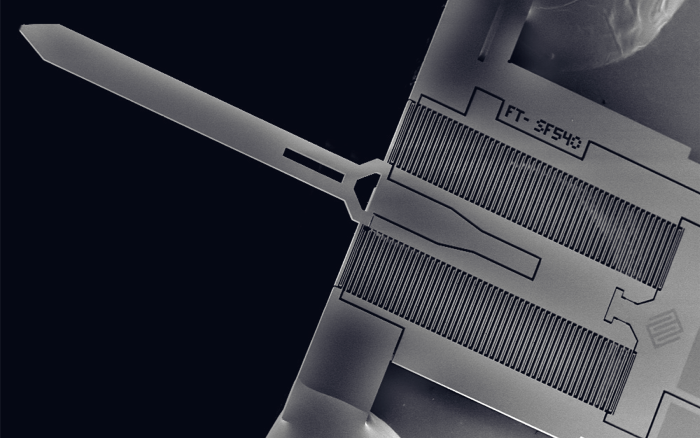

Image Credit: Oxford Instruments Materials Science

The FT-S Microforce Sensing Probes are advanced sensors designed to measure forces ranging from sub-nanonewton to two newtons along the axis of the sensor’s probe. They come in a diverse selection of tip materials and geometries, such as diamond Berkovich, cube corner, flat punch, wedge, conical, and additional options.

Specifications

Source: Oxford Instruments Materials Science

|

Force range |

Force resolution (noise at 10 Hz) |

| FT-S200 |

+/- 200 µN |

500 pN |

| FT-S2’000 |

+/- 2 mN |

5 nN |

| FT-S20’000 |

+/- 20 mN |

50 nN |

| FT-S200’000 |

+/- 200 mN |

500 nN |

| FT-S2’000’000 |

+/- 2 N |

5 µN |

Two-Axis Microforce Sensing Probe

Image Credit: Oxford Instruments Materials Science

The FT-S Two-Axis Microforce Sensing Probes are multi-axis microforce sensors based on Micro-Electro Mechanical Systems (MEMS) that can measure forces simultaneously in two in-plane directions. These sensors are primarily utilized for applications in nano-scratch, nano-tribology, and nano-wear testing.

Specifications

Source: Oxford Instruments Materials Science

|

Force range |

Force resolution (at 10 Hz) |

| Force Sensing |

+/- 20 mN |

100 nN |

| Tangential Force Sensing |

+/- 20 mN |

100 nN |

High-Temperature Microforce Sensing Probes

Image Credit: Oxford Instruments Materials Science

The High-Temperature Microforce Sensing Probes are microforce sensors based on Micro-Electro Mechanical Systems (MEMS) that can measure forces ranging from 200 mN to 2 µN. Additionally, the monolithically integrated tip heater allows for precise matching of the nanoindenter tip temperature to that of the sample, facilitating isothermal testing conditions.

Specifications

Source: Oxford Instruments Materials Science

|

Force range |

Force resolution (noise at 10 Hz) |

| FT-S200'000-HT |

+/- 200 mN |

1 µN |