NTA provides information on particle size distribution of samples in liquid suspension using the properties of both Brownian motion and light scattering.

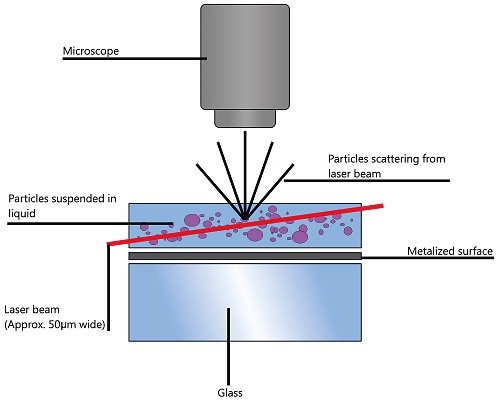

When particles in suspension are exposed to a laser beam traversing the sample chamber, they scatter the light, which makes them visible through a 20x magnification microscope. The camera mounted on this microscope captures the particles’ Brownian motion within its field of view (FOV) of roughly 100µm x 80µm x 10µm as a video file (Figure 1).

Figure 1. Schematic of the optical configuration used in NTA.

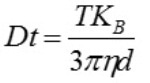

The center of the particles is identified by the proprietary NTA software to determine the average distance traveled by each particle in the x and y directions. From this value, the particle diffusion coefficient (Dt) can be calculated. When the solvent viscosity (η) and sample temperature (T) values are known, the sphere-equivalent hydrodynamic diameter (d) of the particles can be determined with the help of the Stokes-Einstein equation:

Where, KB = Boltzmann's constant.

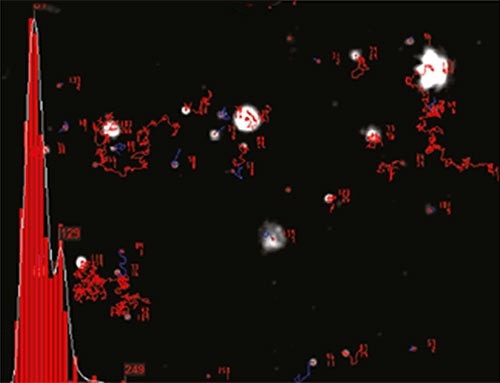

NTA sizes each particle one at a time regardless of the other particles. Figure 2 illustrates the size distribution profile generated by NTA. Since the particles’ motion is tracked within a fixed FOV (roughly 100 µm by 80 µm) irradiated by a laser beam of roughly 10 µm in depth, the sample’s scattering volume can be calculated. The particle concentration within this FOV is measured and extrapolated to a larger volume to estimate the concentration in particles per mL for an overall total or any given size class.

Figure 2. An example of the size distribution profile generated by NTA. The modal size for this sample is found to be approximately 70 nm, with larger sized particles also present.

Nanoparticle Production

As materials on the nanoscale exhibit exotic properties when compared to its bulk counterpart, nanparticles and engineered nanoparticles (ENPs) are gaining traction in a myriad of industries. As a result, it is necessary to obtain accurate size, concentration and size distribution measurements on these nanoparticles. However, existing techniques such as light scattering and electron microscopy are time intensive and provide results that are complex to interpret, especially for heterogeneous samples with varying particle sizes (polydisperse).

NTA in the Design and Production of Nanoparticles

A study used NTA for particle size distribution measurement for the analysis of the impact of ball milling time on the production and consolidation of nanostructured WC-Co composites. The results revealed the increase in the count of nanoparticles below 0.2 µm with milling time. Another study used NTA to explore the impact of milling temperature on the production and consolidation of nanocomposite WC-10Co powders.

While characterizing the particle size distribution of sub-micron particles in liquid suspension, a research group found that the presence of aggregates did not influence the NTA results when compared to other techniques. In another study, Researchers concluded the importance of selecting appropriate surfactant molecules to obtain effective fuel cell catalyst using NTA.

A group of researchers has evaluated the role of polymeric nanocapsules in nanomedicines and nanocomposites using different techniques, including EM and NTA. The application of NTA in the nanoparticle production analyzes by means of both laser ablation and laser pyrolysis had also been demonstrated. NTA was also used to monitor the aggregation process in order to demonstrate the use of strongly coordinated inorganic anions in precursor-directed assembly of complex oxide nanobeads.

In a study, different techniques including NTA, were used to observe the aggregation of α-amino acids into clusters of a size range of 100-200nm suspended in an aqueous solution. Another study with an aim of tuning mechanical properties of liquid crystalline nanoparticles determined the hydrodynamic diameters of the nanoparticles in liquid suspension using NTA. The stoichiometry of alloy nanoparticles from laser ablation of PtIr in acetone as well as their electrophoretic deposition on PtIr electrodes was determined using a modified NTA system.

Nano-Silica

Mesoporous silica is an exotic nanomaterial being studied for its potential applications in imaging, drug delivery, and catalysis. Its refractive index is low and therefore visualizing the smallest size of this nanomaterial (< 40 nm) is a challenge. NTA has been proven as a valuable tool to detect, analyze and characterize these mesoporous nanoparticles.

Nano-Silver

NTA was used in a study to validate the aggregation behavior of silver nanoparticles in order to develop an innovative procedure of continuous fabrication of aqueous dispersions of silver nanoparticles by means of cellulose fibers. In another study, silver nanoparticles were analyzed using a NTA system to explore the influence of pH on zeta potential of the nanosilver powders treated with acetone and IPA.

NTA was also used to explore the anti-microbial effect of silver nanoparticles obtained from Murraya koenigii-mediated synthesis on three human pathogenic bacteria by determining their number concentration and particle size distribution during the synthesis. In a study, biomass-derived stabilizing agents for colloidal silver nanoparticles were evaluated using NTA and the results revealed that NTA is a valuable, easy-to-use, and robust characterization tool for discerning between capping efficiencies of different biomass-derived stabilizing agents in aqueous colloidal silver suspensions.

Gold

The dispersion stability of gold nanoparticles is crucial in drug delivery and other medical applications as it affects their final performances. NTA is useful to assess this important characteristic of gold nanoparticles. NTA was used to determine the concentration, zeta potential, and hydrodynamic radius of plasmon resonant gold nanostars in their application of photothermal ablation and in vivo particle tracking.

NTA was also proven as a simple yet rapid analytical instrument to explore bioconjugation and to analyze protein-protein interactions. In an assessment study of NTA, Researchers concluded its effectiveness to be used as an analytical instrument in the characterization of AuNP bioconjugates, exploring the bonding between proteins and determining the low levels of antigen in a bioassay.

Iron Oxide

NTA was used to study iron oxide (magnetic) nanoparticle synthesis by means of a filtrate of Phoma glomerata (a plant pathogen), revealing that the average size of the polydisperse nanoparticles was to be 56 nm.

In a study aimed at the development of efficient water oxidation catalysts using iron coordination complexes, Researchers used NTA and DLS to analyze the potential of nanoparticle formation in solution. However, the detection limit of DLS was higher than the concentration range of catalytic reactions of nanoparticles in solution (typically below 0.1ppm), making it difficult to provide a reliable size distribution measurement when compared to NTA.

Another study observed aggregation behavior using NTA to demonstrate the improvement in spermiotoxicity due to the stabilization of engineered zero-valent nanoiron with Na-acrylic copolymer. NTA was also used to explore the impact of four common polymers on the sedimentation behavior, colloidal stability, surface chemistry and size of zero valent iron nanoparticles.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information please visit Malvern Panalytical.