Ferritic-Martensitic low-carbon alloy steels exhibit advanced material properties at higher temperatures and as a result they are used in piping, pressure vessels, and nuclear reactors. Grade 91 or P91 alloy (9CrMo) steel (Table 1), has improved creep resistance at higher temperatures.

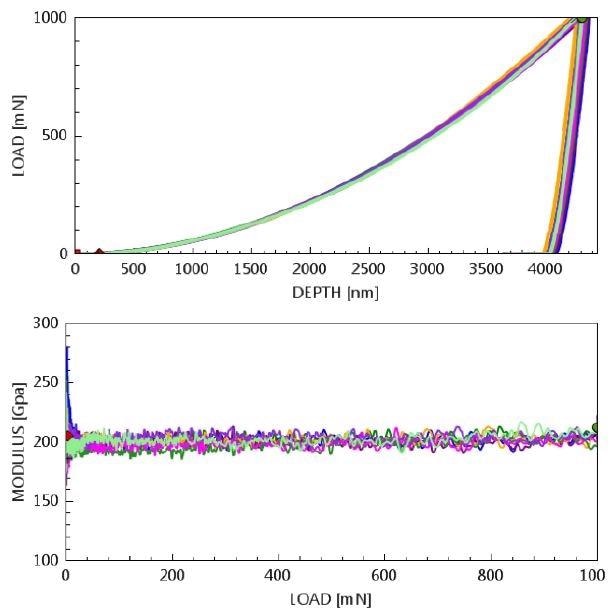

First, the electromagnetic actuation and dynamics of nanoindenters from KLA. are implemented to determine the elastic modulus of grade 91 steel as a function of indentation depth and load (Figure 1).

Figure 1. Nanoindentation testing results on Grade 91 steel using an iMicro nanoindenter. A load is applied and the resulting indentation depth is measured. Material properties, such as elastic modulus, are measured continuously during the load application. This results in a dataset that can be used to assess the mechanical behavior of surfaces.

Table 1. Mechanical Properties and Composition of Grade 91 Alloy Steel

| Typical Mechanical Properties |

Value |

| Ult. Tensile Strength |

585 - 760 MPa |

| Yield Strength |

415 MPa |

| Elongation at Break |

18% |

| Elastic Modulus |

200 GPa |

| Poisson’s Ratio |

0.29 |

| Element |

Weight % |

| Fe |

Balance |

| Cr |

8.00 - 9.50 |

| Mo |

0.85 - 1.05 |

| Mn |

0.30 - 0.60 |

| Si |

0.20 - 0.50 |

| V |

0.18 - 0.25 |

| C |

0.08 - 0.12 |

| Nb |

0.06 - 0.10 |

| N |

0.03 - 0.07 |

NanoBlitz 3D – Rapid Statistical Quantification

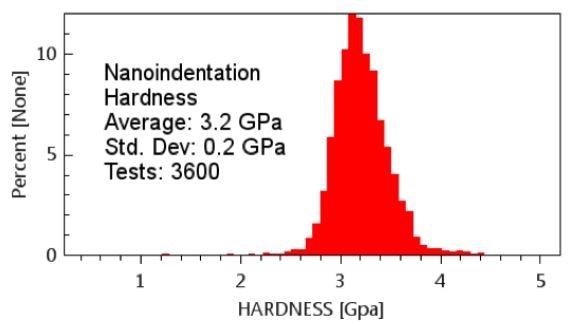

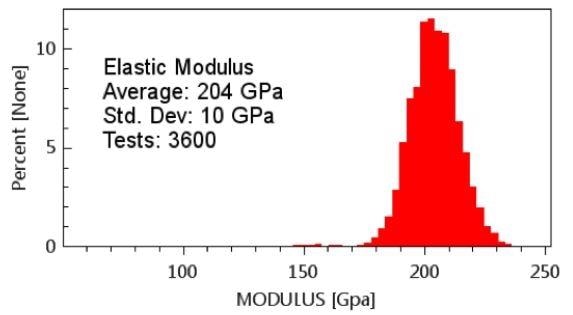

Additionally, the power of high-speed indentation as well as the generation of powerful statistical data with NanoBlitz 3D are also emphasized. A total of 3600 separate indentations were performed over an area of 100 μm x 100 μm using NanoBlitz 3D in an iMicro® system at an applied load of 2 mN. For all 3600 indentations, the total test time was 2800 seconds which resulted in a rapid but large dataset highlighting the NanoBlitz 3D’s statistical power and efficiency.

Figure 2. Probability distribution function of nanoindentation hardness from 3600 individual indents on Grade 91 steel.

Figure 3. Probability distribution function of elastic modulus from 3600 individual indents on Grade 91 steel.

This information has been sourced, reviewed and adapted from materials provided by Nanomechanics, Inc., a KLA-Tencor company.

For more information on this source, please visit KLA.