In this interview, industry experts Derek Nowak and Beihang Yu discuss the use of PiFM for nanoscale chemical imaging and its role in advancing analysis of thin films and other complex material surfaces.

Could you provide an overview of PiFM and how it differs from traditional techniques such as FTIR or Raman spectroscopy?

Derek Nowak: PiFM is a scanning probe-based technique that allows us to chemically image materials at the nanoscale, down to 5 nm spatial resolution. Unlike traditional optical techniques such as FTIR or Raman, which rely on detecting photons, PiFM measures the force generated when a material absorbs light at a specific wavelength. This is done using an atomic force microscopy (AFM) probe, where a tunable laser illuminates the sample, and we detect the resulting light-induced force on the tip.

Traditional FTIR and Raman are limited in resolution, typically in the micrometer range, and often cannot resolve fine spatial features or thin layers. TOF-SIMS can achieve high spatial resolution but is destructive. PiFM is non-destructive, surface-sensitive, and capable of chemically identifying monolayers with high fidelity. In short, it fills a significant surface characterization gap by providing chemical and topographical information at the nanometer scale.

What are some examples of PiFM’s strengths in analyzing complex surfaces or thin films?

Derek Nowak: PiFM’s biggest strengths are its surface sensitivity and ability to resolve chemical features in heterogeneous materials. For example, we have studied blended polymers like PCL and ascorbic acid, where PiFM identified both materials and revealed nanoscale variations in their spectra—variations tied to molecular orientation or crystal structure. Bulk techniques like FTIR cannot capture that because they average over large areas.

Another great example is our work with silicon wafers. Even on surfaces that appear atomically smooth and clean, PiFM has revealed unexpected contaminants like perfluorinated polyethers—often from vacuum pump oil residues—or hydrocarbon layers from ambient exposure post-cleaning. In one case, we traced contamination back to a CVD vacuum chamber. These insights are critical for clients troubleshooting low yields or process variability in their fabrication workflows.

Can PiFM also distinguish molecular orientation or crystallinity within a sample? How does that work?

Derek Nowak: Yes, and that is one of its more advanced capabilities. Because PiFM relies on measuring the directionally sensitive force between a polarized sample and the AFM tip, it is especially sensitive to how molecules are oriented, particularly in crystalline materials.

For instance, in the case of ascorbic acid crystals, we observed differences in peak intensities and actual changes in peak ratios at different points on the sample. This reflects varying molecular orientation within the crystal lattice. Since the PiFM signal is dominated by forces normal to the surface, it is highly sensitive to anisotropic absorption. We can use PiFM to identify what molecules are present and how they are arranged, providing valuable insight into material morphology and function.

Shifting to the collaboration aspect—Dr. Yu, can you tell us about your research and what challenges led you to use PiFM?

Beihang Yu: I am a postdoc at Lawrence Berkeley National Lab, and my work focuses on engineering semiconductor-bio interfaces using sequence-defined polymer brushes—specifically, polypeptides. We graft these ultra-thin materials onto substrates to enable precise surface functionalization, crucial for selective biomolecule binding in biosensing and nanoelectronics.

The challenge was confirming whether our grafting strategy—particularly using carboxylic acid or hydroxyl functional groups—was actually working at the monolayer level. Traditional characterization techniques, such as water contact angle or ellipsometry, gave inconclusive results, especially because we are working with ~1 nm thick films. We needed a technique that could chemically map these materials with nanometer resolution and monolayer sensitivity, and PiFM was exactly what we needed.

What did PiFM reveal about your initial attempts at grafting polypeptoid brushes to silicon surfaces?

Beihang Yu: Initially, we tried grafting polypeptoids with a carboxylic acid (COOH) group, which we thought would react well with the silicon surface. We saw a water contact angle change, which suggested something had happened, but when we sent the samples to Molecular Vista, PiFM revealed that we had only sparsely grafted fragments—nowhere near the full monolayer we expected.

In contrast, when we switched to hydroxyl (OH) functional groups and followed the same process, PiFM showed significantly higher surface coverage. Not only did the IR spectra match what we expected from polypeptoids, but the images showed a relatively uniform and smooth distribution. We could not confirm this with any other method, and it changed how we approached surface preparation and functional group selection.

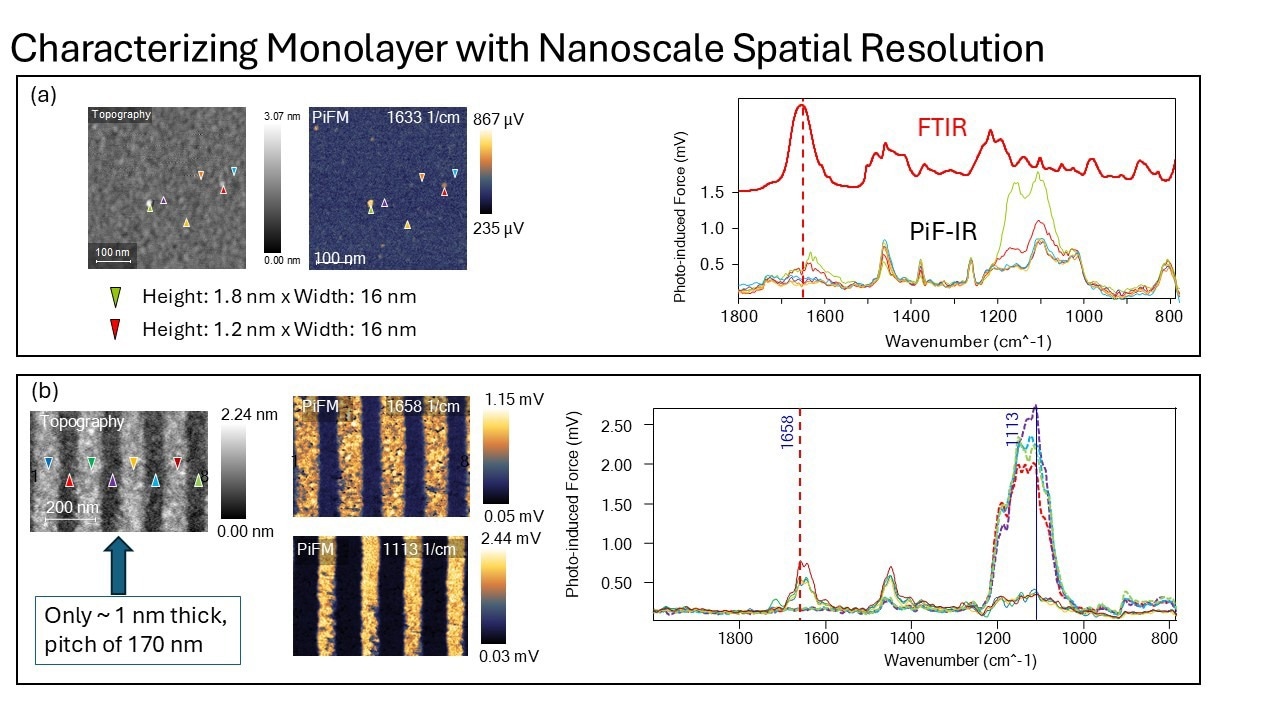

Panel (a) shows what was thought to be a monolayer. However, the spectra taken on flat surface show no sign of the amide peak at 1658 cm-1. Nevertheless, the spectra taken on particles of 1.8 nm and 1.2 nm (the height is the accurate measurement of the particle size since the metal-coated tip has a tip radius of curvature of ~ 20 nm, which will make the particle look bigger) show the amide peak. This allowed us to determine that the monolayer was not formed. The PiFM image at 1633 cm-1, shows that are a few clusters of peptoid molecules on the surface.

Panel (b) shows the grafting chemistry was changed after the failed attempt. With the hydrosyl (OH) functional group, the monolayer could be formed reliably. The monolayer is only ~ 1 nm thick, but it could be reliably patterned via e-beam lithography. The PiF-IR spectra taken on the raise portion (dark blue, green, gold, and dark red) show the amide peak clearly whereas the spectra taken on the substrate (red, purple, blue, and lime green) show no sign of amide and very strong silicon oxide peak. The PiFM image at 1658 and 1113 cm-1 clearly highlight the peptoid and silicon substrate regions. Image Credit: Molecular Vista

Once you optimized the grafting, were you able to integrate the polypeptoids into lithographic workflows?

Beihang Yu: Yes, and that was a major milestone for us. We used electron beam lithography to pattern the grafted monolayers, and then went back to PiFM to see if the chemical integrity of the polypeptoids was preserved. The results were extremely encouraging.

When we imaged the patterned surfaces at 1658 cm-¹, which corresponds to the amide carbonyl stretch, PiFM clearly highlighted the polypeptoid lines while the trenches remained dark. We also compared the spectra from patterned and unpatterned regions, and they were nearly identical. That confirmed that the polypeptoids remained chemically intact through lithography and that we could use them in nanofabrication processes with confidence.

Were there any surprising findings that PiFM uncovered or things you did not expect from your standard workflows?

Beihang Yu: One big surprise was how misleading water contact angle measurements can be. In some cases, we observed similar contact angles for the carboxylic and hydroxyl polypeptoids, even though PiFM later showed that only the hydroxyl variant had formed a complete monolayer. That highlighted the need for nanoscale chemical characterization.

PiFM also helped us understand the effects of contamination from air exposure or storage materials like siloxanes. We saw unexpected chemical signatures on some substrates, forcing us to improve our sample handling and storage protocols. These kinds of subtle, process-level insights are hard to gain without a technique as sensitive and spatially resolved as PiFM.

Want to know learn more about PiFM? Click here for an exclusive webinar

Beyond materials science, are there broader implications for using PiFM in biological or hybrid applications?

Beihang Yu: Absolutely. One of our initial motivations for developing this platform was to selectively bind biomolecules to patterned surfaces for biosensing and protein studies. With PiFM, we can confirm that our functional layers are present and chemically active, down to the monolayer.

We are already starting user collaborations for applications like single-molecule dynamics and protein structural studies. PiFM could also be incredibly useful in studying soft matter or enzyme interactions on modified substrates. It is a game changer for anyone needing spatial resolution and chemical specificity, especially at bio-interfaces or in nanoengineered systems.

Looking ahead, what do you see as the future of PiFM in research and industry?

Derek Nowak: We are only scratching the surface of what PiFM can do. In research, I see it being increasingly adopted for materials discovery, polymer science, and nanoscale catalysis. It is already proving invaluable for process diagnostics in industry, especially in semiconductor fabrication, where surface chemistry is critical. One specific application that we are targeting is automated review of defects on wafers found by wafer inspection tools. This automated review is typically performed on review SEM/EDX systems. However, EDX on organic defects are not of much help in their identification and even prone to be contaminating and potentially destructive on ultra-small defects (sub-20 nm). Automated defect review based on PiFM would provide valuable 3D topographic data along with chemical speciation of both organic and inorganic defects non-destructively, which would prove to be invaluable.

Because PiFM combines spectroscopy with nanometer resolution, it is uniquely positioned to address questions that no other tool can answer as comprehensively. We continue developing new capabilities—like faster acquisition, expanded spectral range, and improved user interfaces—to make it even more accessible. Whether you are a scientist working on thin films or an engineer debugging a manufacturing line, PiFM has the potential to become a go-to diagnostic tool.

References and Further Reading

Yu, B., Chang, B.S., Loo, W.S., Dhuey, S., O’Reilly, P., Ashby, P.D., Connolly, M.D., Tikhomirov, G., Zuckermann, R.N. and Ruiz, R., 2024. Nanopatterned monolayers of bioinspired, sequence-defined polypeptoid brushes for semiconductor/bio interfaces. ACS Nano, 18(10), pp.7411–7423. https://doi.org/10.1021/acsnano.3c10204

About Derek Nowak

Derek Nowak holds a Ph.D. and M.S. in Physics from Portland State University, and a B.S. in Physics and Astronomy from Northern Arizona University. At Molecular Vista, he has been instrumental for over a decade, progressing from Staff Scientist to Vice President of Technical Operations, where he leads development in advanced scanning probe microscopy technologies.

About Beihang Yu

Beihang Yu holds a PhD in Chemical Engineering from UC Santa Barbara and a dual bachelor's degrees in Polymer Materials Engineering and English from Tsinghua University. Currently a Postdoctoral Scholar at Lawrence Berkeley National Laboratory, she works on advanced polymer systems for semiconductor and biointerface applications.

This information has been sourced, reviewed and adapted from materials provided by Molecular Vista.

For more information on this source, please visit Molecular Vista.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.