Jul 1 2016

The invention of the carbon nanobrush, which is a new nano carbon material, was announced by NEC Corporation on June 30, 2016. Carbon nanobrush is a fibrous aggregate of carbon nanohorns that are single-walled. NEC has globally become the first company to develop the carbon nanobrush.

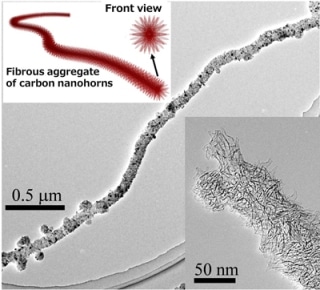

TEM images of the obtained samples (Credit: NEC Corporation)

TEM images of the obtained samples (Credit: NEC Corporation)

Carbon nanohorns are nano carbon structures that are horn-shaped and measuring 40-50nm in length and 2-5nm in diameter. Until now, these nanohorns have been developed as radial spherical aggregates. The carbon nanobrush is a material that has been shaped in a very unique manner. It is made up of fibrous aggregates containing radially-assembled graphene-based single-walled nanotubules, referred here as fibrous aggregates of single-walled carbon nanohorns with a structure that is similar to that of a round brush.

"The 'carbon nanobrush' is a new nano carbon material that, like existing carbon nanohorns, has high water and solvent dispersity, and high adsorptivity, including substance adsorption, but has more than 10 times the electrical conductivity than existing carbon nanohorns, an important characteristic for industrial applications," said Dr. Sumio Iijima, Senior Research Fellow, NEC Corporation.

With these characteristics, it is anticipated that the carbon nanobrush will help to improve the basic functionality of a range of devices, including increasing the speed of sensor and actuator responses, improving the output properties of batteries and capacitors, while increasing the electrical conductivity of rubber and plastic composite materials, as well as having application in a wide range of industries.

Dr. Sumio Iijima, Senior Research Fellow, NEC Corporation.

The carbon nanobrush includes the following features:

1. Structure

- Single-walled carbon nanohorns measuring 40-50nm in length and 2-5nm in diameter radially assemble and bond fibrously in numerous micrometers.

- The horn-shaped single-walled carbon nanohorn has a huge surface area and radially assembles and fibrously binds together in numerous micrometers. Hence, it has a huge surface area per unit mass (up to 1700㎡/g).

2. Characteristics

- Dispersity: The carbon nanobrush, just like carbon nanohorns, comprises high dispersibility, for example, dispersing in organic solvents and water. This highlights the fact that the carbon nanobrush is capable of easily blending with a wide range of materials, thus easily enhancing its characteristics as a base material.

- Adsorptivity: The carbon nanobrush, like the spherically-shaped carbon nanohorns, can contain a wide range of substances in the nano-sized spaces existing inside the tubular structure, hence it can be used as a high-performance adsorbent. The development of holes on the surface of the carbon nanohorns through oxidation treatments allows the usage of the inner space, majorly increases adsorptivity and expands the surface area by an approximate factor of five.

- Electrical conductivity: When compared to the existing spherically-shaped carbon nanohorn aggregates, the carbon nanobrush has more than ten times of electrical conductivity because it is a fibrous aggregate of carbon nanohorns that are radially-assembled. Thus, they play a vital role in effectively improving the sensor’s speed and the actuator responses. They also increase the output characteristics of capacitors and batteries, and further enhance the electrical conductivity of plastic composite materials and rubber.

3. Production process

Carbon nanobrush can be developed under atmospheric pressure and at room temperature through the laser ablation method in which an iron-containing carbon target (carbon mass) is illuminated by a high power density laser. The production process of the carbon nanobrush is simple, thus enabling efficient production in a cost-effective manner when compared to the cost various other nano carbon materials.

This technology was partially developed through a joint research with the National Institute of Advanced Industrial Science and Technology (AIST).

The latest research findings are published in the June 1, 2016 issue of Advanced Materials.