A New Decade of Innovation

Ten years is ample time for market disruption and adaptation in the Atomic Force Microscope (AFM) industry. Park Systems Corp. (Park) typically delivers a major new platform every decade.

The capabilities and features of the preceding products foretell the product and business strategy for the coming decade. Building upon the crosstalk elimination design benefits of the XE-series AFMs, Park integrated industrial automation technology and capitalized on these strengths to move into the hard disk market.

With the lower noise design of the NX-series AFM, precise measurement data on large samples became a reality, and Park then moved successfully into the semiconductor industry.

Park Systems' current goal in pioneering the user interface for AFM automation is to ensure that the FX product line will facilitate the next generation of AFM solutions for applications that have traditionally been supported by long-established microscopy industries such as electron and optical. As with the XE-series and the NX-series that preceded it, the FX-series has ambitious goals to make the Park AFM the technology of choice for applications previously dominated by other measurement technologies.

Figure 1. From XE to FX: Park Systems AFM product line has undergone a major renewal every decade. Image Credit: Park Systems

Is AFM Easy to Use?

The primary objective of AFM is to simultaneously measure three dimensional surface topography and other physical properties, both reliably and repeatably, with sub-nanometer resolution. Sample preparation is nominal, if required at all, and the cost of ownership is much lower than related techniques.

Therefore, AFMs are now considered indispensable tools in industrial and research applications. Large-scale acceptance of AFM, however, was initially restrained by complex operational knowledge that was often required of new users before they were comfortable with operating the AFM and trusted the data they obtained.

Although commercial AFMs have improved over time, AFM is still hard to learn and operate for many new users with no previous experience.

Historically, sometimes tedious researcher setup and manual input were required for AFM operation. Before acquiring any AFM data, a user must choose an appropriate probe, mount it (often using tweezers), and then manually align the optical detection system and viewing optics.

Following these steps, a sample must be loaded, typically with one or more areas selected for imaging and analysis. The user must then select an imaging mode, tune the system, and carefully bring the tip into feedback before proceeding to image the sample surface.

To acquire valid surface information, the user must make several adjustments to ensure that the AFM properly tracks the sample surface. These potentially complex procedures have inhibited AFM from going mainstream as it usually requires someone with great experience to obtain good, reproducible data.

Improved user convenience and better or enhanced performance are two differentiating factors targeted to separate the new FX-series from other systems. Improved user convenience is achieved by making primary operational steps motorized and automated. Better performance, on the other hand, indicates improved specifications and additional (or new) capabilities a tool may posess that provides a justifiable benefit to the user.

While AFM manufacturers are competing on scan speed, resolution, or even lattice imaging, Park finds automation to be the request coming from the AFM community that has the greatest potential to disrupt and expand the market.

Figure 2. How Park will contribute to market needs of the AFM industry. Automation is a major central theme in Park’s R&D efforts, followed by system performance or resolution. Other agenda items such as lattice imaging and scan speed are considered for specific sample and measurement needs. Image Credit: Park Systems

FX: "The Dream Machine Project"

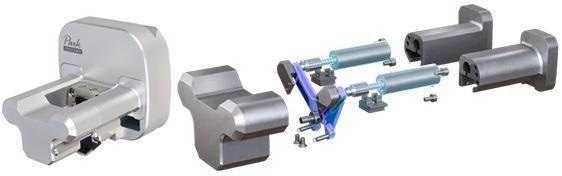

The Park FX40 AFM was the dream machine project with the objective of designing and producing an AFM that optimizes user convenience while introducing new features and enhancing performance.

From the initial stage of product design, user convenience enhancements were to include the full automation of probe exchange, beam alignment, and sample positioning. Performance-wise; system noise floor, servo performance, and optical vision were to be improved upon from the previous generation system.

The development of the Park FX40 built upon the experience acquired using crosstalk elimination technology on the previous generations of Park AFMs.1 The Park Systems' trademark is the use of two dedicated, completely independent flexure scanners, one for sample (XY) and the other for probe (Z) movement. By implementing this scanner design, the raw out-of-plane-motion (OPM) prior to image correction is less than 2nm over an 80µm scan range, facilitating precise measurements from raw sample data and negating the need for software levelling corrections that render measurements less reliable.

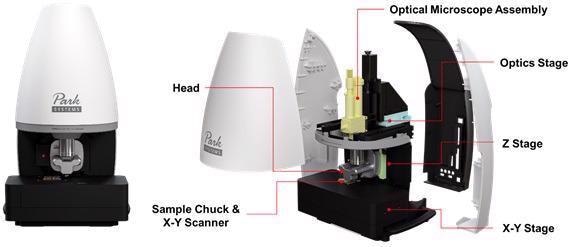

The FX-series' general design is based on the robust, mechanical design that proved successful in both the NX- and XE-series. The Optical Microscope Assembly of the Park FX40 is fixed in the system’s center. The AFM head is located along the center axis of the Optical Microscope Assembly and moves with the Z stage. The sample chuck and the XY scanner on the XY stage are located directly beneath the AFM head.

Figure 3. Front view of the Park FX40. The view on the right reveals some major components normally hidden by the microscope housing. Image Credit: Park Systems

The Optical Microscope Assembly is fixed to the focus stage and can move vertically. In contrast to the existing NX-series AFM system, the focus stage is not fixed to the Z stage but separately rides on an optics stage. Such an arrangement limits the weight on the Z stage, making the system more stable and immune to external vibrations.

Combined with a more robust Z stage, built on a high stiffness cross-roller guide and two bearing blocks, the Park FX40 accomplishes a lower mechanical noise floor than the previous NX-series and XE-series AFM systems.

Furthermore, the optics stage moves the optical microscope assembly in the XY plane, a design consideration crucial for AFM automation.

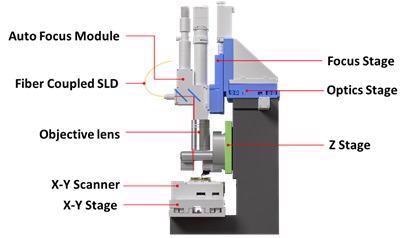

Figure 4. The Optical Microscope Assembly is decoupled from the moving plate of the Z stage, reducing the total Z-stage mass. A fiber coupled SLD is attached to the Optical Microscope Assembly. The SLD beam is focused through the objective lens and always fixed at the center of the optical view. Image Credit: Park Systems

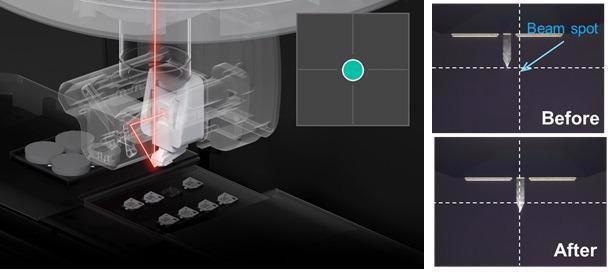

The main elements of the Optical Microscope Assembly are equivalent to prior XE- and NX- generations and include an objective lens, tube lens, camera, and LED light source for optical vision. The main difference is a fiber-coupled super-luminescent diode (SLD) is located on the side port of the FX- Optical Microscope Assembly.

The objective lens focuses the SLD beam onto the AFM cantilever and fixes its position at the center of the optical view. The objective lens allows the FX40 to create an extremely small target beam spot size, facilitating the use of a broad range of cantilever sizes and applications.

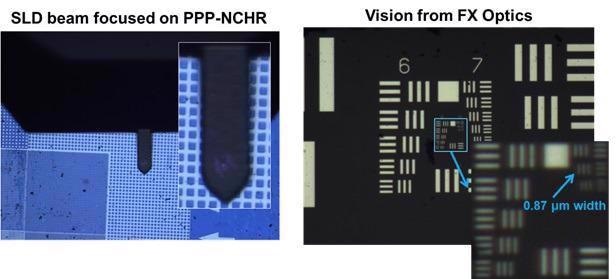

Figure 5. Focusing the SLD beam through an objective lens results in a small beam spot on the back of the cantilever for improved performance. The updated FX optics can resolve 0.87 µm linewidth. Image Credit: Park Systems

Optical vision quality, a crucial component of industrial automation, was significantly enhanced compared to the NX-series AFMs.

In the FX AFM head design, all elements of obstruction, such as a beam splitter, present in earlier designs were eliminated to optimize the optical beam path. The optical vision of the Park FX40 can resolve line pairs with a width of less than 1 µm.

New FX Features

The Park FX40 has the most sophisticated AFM design and interface with the goal of maximizing user convenience. State-of-the-art automation, which includes automatic probe exchange and SLD beam alignment with the click of a button and utilizing pattern recognition, is the primary design feature that facilitates system operation.

Inside the FX40 are three camera modules:

- A primary view camera located at the system center

- A sample view camera located on the left side of the system

- A QR code reader located on the right side

The automatic tip exchanger (ATX) module is situated on the right side of the XY stage, and it can hold up to eight AFM probes. A sliding protective cover stops foreign objects from falling into the ATX module when it is not in use.

Figure 6. The main components of the FX40 system include the ATX module (shown on the right) and three camera modules: a primary tip/sample view , a wide-angle sample view, and a QR code reader. Image Credit: Park Systems

Probe Loading

Probe loading is the biggest obstacle for novice AFM users. The NX- and XE-series AFM systems addressed such challenges by utilizing pre-mounted probes.2 In the Park FX40, new probes can be automatically exchanged safely and easily from an 8-probe cassette.

Once the probe cassette is placed onto the ATX module, the probes may be exchanged automatically onto the AFM head. The user also has the ability to manually replace individual probes and mount them onto a probe hand, just like with the XE and NX series systems.

Figure 7. Probe cassette exchange entails placing an 8-probe cassette atop the ATX module and unscrewing the locking knob to open the cassette cover. Image Credit: Park Systems

Probe Exchange

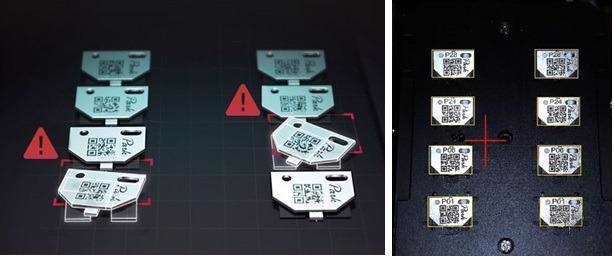

Much like the automatic probe exchange on Park’s industrial inline AFMs, probes are collected by a magnetic force control mechanism.3 The QR code reader identifies the probe ID and the status of ATX slots.

A vision recognition-based machine learning algorithm automatically tracks whether or not probes are loaded onto their assigned positions in the ATX cassette and produces a status report if an error is detected during probe loading. The machine learning algorithm analyzes and tracks a number of factors, such as the shape of Park’s patented chip carrier and the loading position, in order to monitor and control successful or unsuccessful routines. This generates improved loading success rates over time.

Figure 8. Automatic detection of probe loading position. Smart vision recognition with a machine learning algorithm locates the position of a loaded probe. Image Credit: Park Systems

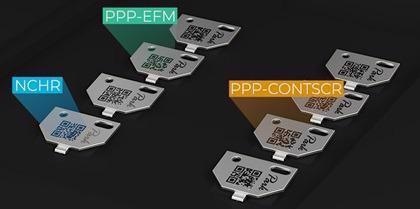

The QR code imprinted on the chip carrier of each probe includes information for probe identification, including the serial number and probe type.

With this information, the physical probe properties, such as cantilever geometry, drive percentages, quality factor, resonant frequency, spring constant, and tip geometry, can be accessed from a database

Once identification of the probes has been conducted, the operator can choose an appropriate probe to use and the Park FX40 selects a probe automatically from the cassette. Subsequently, the FX40 finds and mounts the cantilever and the super-luminescent diode (SLD) and photodetector are automatically aligned.

Figure 9. The QR code reader identifies the probe type by reading the QR codes on the chip carriers in the probe cassette. Image Credit: Park Systems

Beam Alignment

With Park’s new automated beam alignment, the SLD beam position is automatically aligned for precise, optimal positioning onto a cantilever. The SLD is fixed to the optical microscope assembly and the SLD beam is permanently fixed at the center of the optical microscope. Utilizing the XY motor adjustments of the optics stage, the cantilever can be positioned at the center of the optical view, and the SLD beam will be automatically positioned onto the back of the cantilever. Based on the machine learning of a probe pattern, the position of the probe is detected by vision recognition.

Figure 10. Due to the fixed position of the SLD, centering the cantilever in the middle of the optics immediately aligns the SLD. Image Credit: Park Systems

The SLD beam that emerges from the objective lens is automatically positioned onto the cantilever and reflected onto a position-sensitive photo-detector (PSPD) using a steering mirror.

To complete the alignment of the beam-bounce, two motors within the FX AFM head modify the angle of the SLD beam steering mirror to point the SLD beam onto the optimal location on the position-sensitive photodetector (PSPD).

This level of automation completely eliminates user error during the complex beam alignment process and guarantees faultless, precise alignment.

Figure 11. The new motorized FX AFM head optimizes the SLD beam spot position on the PSPD both vertically and laterally for optimal operation. Image Credit: Park Systems

Sample Navigation

The FX40 system is equipped with a Multi Snap-in Sample Chuck. Users can populate the sample chuck by taking advantage of four kinematically mounted sample plates. In both X and Y, the positioning repeatability of the sample disks is 5 μm.

Utilizing four sample plates with repeatable positioning facilitates easy comparison between reference and target samples for measurements that may include, KPFM (kelvin probe) work function, PinPointTM nanomechanical, SCM (scanning capicitance) dopant concentration or SThM thermal.

Figure 12. The Multi Snap-in Sample Chuck is the default sample chuck for Park FX40. The discs are kinematically mounted to ensure mounting repeatability. Image Credit: Park Systems

The FX40 system utilizes a low-magnification sample view camera to assist the operator in navigating to the imaging location desired. As the user selects positions on the optical view screen, the clicked position of the XY stage coordinate is recognized, and the XY stage moves to locate the required measurement position directly beneath the probe tip.

Figure 13. Sample navigation is simplified with the default off-axis sample view camera and fast moving XY stage. The picture on the left indicates the physical location of the camera while the right picture depicts an actual screen shot of the sample stage. Image Credit: Park Systems

For precise navigation on an individual sample, it is possible to use the high-resolution optical view from the on-axis main view camera. Once sample navigation is completed, the cantilever then approaches the selected sample location automatically.

For rapid engagement to sample surface, the sample height is measured by an innovative auto focus module. The tip approach is assisted by monitoring the effect of air damping while the probe approaches the sample surface.

The vibration amplitude of the cantilever decreases monotonically and then linearly until the interatomic force draws the tip to the surface at a threshold distance. This air damping effect can be utilized for an automatic tip approach to guarantee a rapid and gentle tip-sample approach.

Imaging

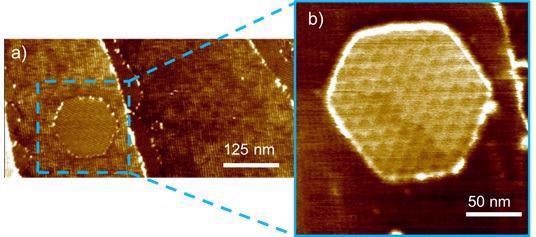

SmartScanTM is a user-friendly interface that facilitates the automation of the entire imaging process and can assist in the selection of imaging parameters based on objective boundary conditions and settings. It carries out all the necessary imaging operations and intelligently selects parameters that will result in the best image quality for a given scan speed.4 This guarantees consistent data quality which is independent of the experience level of the operator. Processes such as the cantilever frequency sweep, gain adjustment, setpoint selection, and scan speed setting are part of the automization routine.5 Automating these processes significantly reduces the time normally taken for manual user inputs and trial and error adjustments. The images in Figure 15, which clearly reveal Moiré patterns of graphene on h-BN, typify the high resolution results that may be obtained on the FX, independent of user experience level.

Figure 14. Moiré pattern observed on graphene on h-BN. a) Topography scan of graphene on h-BN, vertical scale 0 to 6 nm. b) Zoom in: Moiré pattern clearly visible, vertical scale 0 to 6 nm. Image Credit: Park Systems

After the data acquisition process is complete, the software secures the system by moving the Z stage upwards, away from the sample, and switching the SLD off. The probe is then returned to the ATX cassette if the operator has no plans to use it immediately.

Other FX Features

There are additional groundbreaking features of the Park FX40 that enhance operating safety and servicing of the AFM.

Multiple built-in sensors measure critical environmental conditions such as humidity, temperature, light, acoustical noise, leveling, and vibration near the system. The environmental conditions measured are displayed in SmartScanTM and saved with the image data file, facilitating the comparison of scanned images with various environmental conditions. Having access to these environmental indicators at any point in time may be useful to users as well as customer service engineers.

Figure 15. Various sensors monitor environmental conditions of the AFM measurement including temperature, humidity, and vibration. Image Credit: Park Systems

Lastly, a new head crash prevention system, which uses a software interlock and hardware switch, has been developed to protect the probe and the AFM scanner from damage. A dedicated circuit monitors the SLD beam deflection and Z-detector signals in real-time, and safety intervention by an algorithmically programmed circuit ensures that the Z stage will not descend beyond the limit of a tip collision with the sample surface. This gives peace of mind to any user that their AFM system and sample are always safe from damage.

Summary

Park refreshes its product line every 10 years with a new platform, and the features and performance of the previous product forecast the product, targeted solutions, and business strategy of the coming decade.

AFM is often cited as being challenging to learn and to operate by many engineers and scientists. To overcome this reputation, Park Systems has introducedThe Park FX40, a next-generation, research-grade, automated AFM platform with fully automated probe exchange and beam alignment, that utilizes machine-learning technology to overcome these challenges.

With simplified sample navigation and an intelligent scan algorithm, the Park FX40 makes enhanced performance and productivity accessible to everyone; new and experienced users alike.

With the Park FX40, meaningful, high-definition data is just a few clicks away.

Acknowledgment

Based on materials originally authored by Ryan Yoo from Park Systems

Mr Yoo wants to thank Dr. Stefan Kaemmer and Dr. Gilbert Min of Park Systems Americas for proofreading and editing the article, Rachel Bang for preparing the list of patents and publication, Kenneth Kang for the figures and schematics, and lastly Dr. Sang-il Park, founder and CEO of Park Systems Corp., for his technology vision and generous comments and feedback during product development and launch preparation of Park FX40.

References

- Joonhyung Kwon, Jaewan Hong, Yong-Seok Kim, Dong-Youn Lee, Kyumin Lee, Sang-min Lee, and Sang-il Park, “Atomic force microscope with improved scan accuracy, scan speed, and optical vision”, Rev. Sci. Instrum. 74, 4378 (2003).

- US 6,945,100 B2 – Scanning probe microscope with improved probe tip mount – Sep.20,2005

- US 8,099,793 B2 – Scanning probe microscope with automatic probe replacement function – Jan.17,2012

- US 9,645,169 B2 – Measurement apparatus and method with adaptive scan rate – May.9,2017

- US 10,133,052 – Image acquiring method and image acquiring apparatus using the sample – Nov.20,2018

This information has been sourced, reviewed and adapted from materials provided by Park Systems.

For more information on this source, please visit Park Systems.