From materials research to biological sciences, nanotechnology to semiconductor manufacturing, TEM is a critical tool for pushing the boundaries of scientific knowledge.

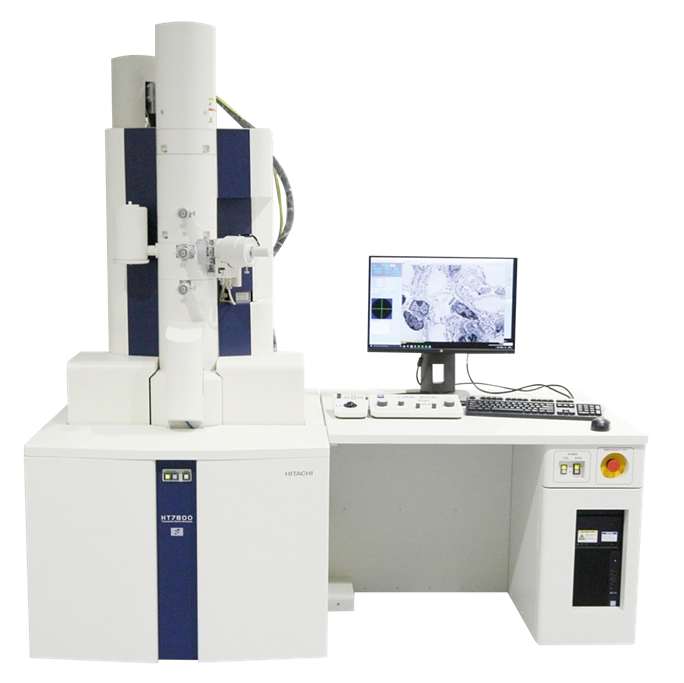

Image Credit: Hitachi High-Tech Europe

In recent decades, technological advances have significantly expanded the capabilities of TEM instruments, making them more accessible to a wider range of academics and industries. Advances in cryo-electron microscopy, for example, have created new opportunities to examine biological molecules in their natural condition.

The Hitachi HT7800 series tackles many of these current difficulties square on. Its simplified operation and versatile imaging system make it an ideal TEM for researchers that require high-quality imaging, efficiency, and ease of use.

Whether you work in biomedical research, materials science, or industrial quality control, the HT7800 provides the precision and versatility you require without the complexities of earlier TEM systems.

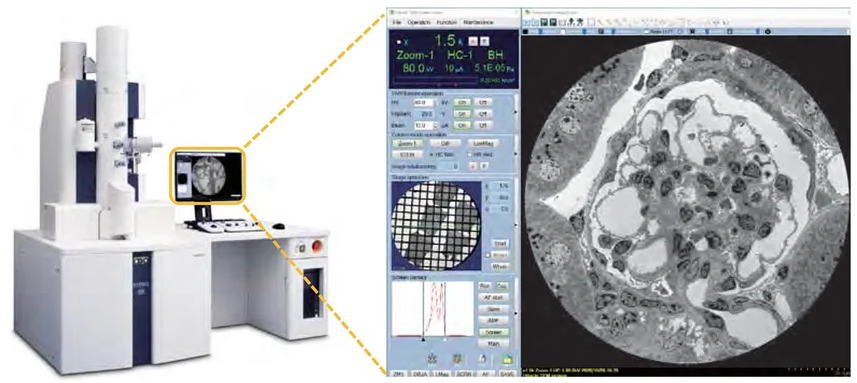

Image Credit: Hitachi High-Tech Europe

Challenges of Modern Electron Microscopy

As research techniques continue to evolve, traditional TEM systems are finding it harder to keep pace with the demands of today’s labs. Scientists and engineers across a wide range of disciplines are, therefore seeking solutions that offer higher precision, greater ease of use, and the flexibility to adapt to shifting research needs.

Here are some of the major obstacles that researchers confront when working with traditional TEMs:

1. The Demand for High-Quality Imaging in Various Applications

Different research applications demand different imaging approaches, but many traditional TEM systems force a trade-off: high contrast for biological specimens or high resolution for materials science. Switching between these modes often requires multiple systems, driving up costs and adding complexity to already demanding workflows.

Beam sensitivity is another major challenge, especially when working with unstained or cryopreserved biological samples.

These specimens are particularly vulnerable to electron beam damage, making low-dose imaging techniques essential for preserving structural detail. However, not all TEM systems are equipped with the advanced digital imaging tools needed to balance sensitivity and resolution, limiting the quality and reliability of results when working with delicate materials.

2. The Complexity and Learning Curve in TEM Operation

Many TEM systems require substantial human control, which means that even simple activities like focusing, altering beam strength, and taking high-quality images can take time and require specialized expertise. This introduces a steep learning curve for new users and reduces research productivity.

To improve efficiency, modern research labs require automated systems that simplify routine procedures such as picture acquisition, sample navigation, and data processing. By lowering the number of manual modifications required, automation can help both new and expert users get consistent, high-quality results more quickly.

3. The Demand for Versatile, Multi-Functional TEMs

Today’s research is increasingly interdisciplinary, and that means labs need tools that go well beyond standard imaging. Techniques like scanning transmission electron microscopy (STEM) and energy dispersive X-ray spectroscopy (EDX) are essential for gaining deeper insight into sample composition and structure.

Without access to these capabilities in a single system, labs are often forced to either invest in multiple instruments or compromise on analytical depth, making research more costly, less efficient, and harder to scale.

4. The Need to Improve Ergonomics and Workflow Efficiency

Many classic TEMs require darkroom conditions, which might be uncomfortable during extended working sessions. The requirement for a specialized viewing chamber limits not only lab layouts but also the number of individuals who can access the equipment simultaneously.

Modern researchers want a more comfortable, well-lit working space that maintains imaging precision. A TEM that does not require a darkroom but still produces high-quality images can dramatically enhance user experience and workflow efficiency.

Image Credit: Hitachi High-Tech Europe

How the Hitachi HT7800 Solves These Challenges

The Hitachi HT7800 series is designed to meet the most pressing difficulties in modern electron microscopy by combining high-quality imaging, automation, versatility, and ergonomics in a single device.

Unlike classic TEMs, which need substantial manual operation or several instruments for varied imaging demands, the HT7800 simplifies processes and makes high-resolution imaging more accessible.

1. Optimized Imaging with a Dual-Mode Objective Lens

One of the most difficult aspects of TEM imaging is striking a balance between contrast and resolution for various sample types.

The HT7800 eliminates this trade-off with its Dual-Mode Objective Lens, which allows you to switch between High Contrast and High-Resolution modes depending on your sample requirements. By combining both modalities into a single system, the HT7800 saves time, money, and lab space while enhancing image versatility.

2. Simplified Operation and Automation

The HT7800 is also designed for ease of use, eliminating the complexity that is common with traditional TEM systems. It has automated functionalities that enable both expert and novice users to get high-quality outputs with little effort:

- Auto Multiple Frame (AMF) imaging automatically captures and stitches high-resolution images, eliminating the need for human alignment.

- Automated navigation and mapping identify and analyze regions of interest without ongoing changes.

- Drift correction and auto pre-irradiation improve image consistency by decreasing sample drift and optimizing beam exposure.

These characteristics serve to reduce training time, eliminate human error, and improve workflow efficiency, making the HT7800 a viable option for high-throughput research applications.

3. Multifunctional and Expandable for Advanced Research

Most research today is interdisciplinary; therefore, a TEM must provide more than simply imaging—it must also combine several analytical techniques.

The HT7800 was designed with expandability in mind, making it an excellent choice for biological, materials, and industrial research. It facilitates:

- The evolution of STEM hardware, allowing for comprehensive EDX analysis, mapping, and cost-effective hardware packages

- Classic scanning transmission microscopy using HHADF

- 3D electron tomography accurately captures three-dimensional structures for biological sciences and materials research

- MirrorCLEM technology enables correlative light and electron microscopy, closing the gap between fluorescence imaging and high-resolution electron microscopy. With these built-in and expandable features, the HT7800 responds to changing research requirements, allowing users to create processes and integrate numerous approaches in a single system.

4. Designed for Comfort and Productivity

Traditional TEMs frequently require darkroom conditions, which can be uncomfortable for long-term users. The HT7800 overcomes this restriction, allowing researchers to operate under typical room lighting settings using an integrated CMOS screen camera.

- Intuitive software and digital tools simplify operation for people of all skill levels

- High throughput and compact design optimize lab space for effective data capture

The HT7800 prioritizes ergonomics and usability, resulting in a more comfortable and productive research experience, making it an invaluable tool for both academic and industrial labs.

The following section looks at how different sectors and research fields can profit from the HT7800's capabilities.

Image Credit: Hitachi High-Tech Europe

Who Benefits from the HT7800?

The Hitachi HT7800 TEM is intended to suit the varying requirements of many research and industrial fields. The advanced capabilities and user-friendly design make it a vital tool for:

Biomedical Researchers:

- Cellular and Tissue Analysis: The HT7800’s high-contrast imaging capabilities make it ideal for detailed visualization of cellular structures, tissues, and biomolecules—helping researchers better understand disease mechanisms and biological processes.

- Pharmaceutical Applications: In drug development and quality control, the HT7800 has been used to analyze viral particles, providing the quantitative data needed to support gene therapy research and manufacturing.

Materials Scientists:

- Nanomaterials Research: With its high-resolution mode, the HT7800 enables close examination of nanoparticles, thin films, and other nanostructures, driving progress in nanotechnology and advanced materials.

- Polymers and Composites: The system’s flexibility allows researchers to study complex polymer and composite materials, supporting both innovation and quality assurance efforts.

Industrial and Quality Control Laboratories:

- Semiconductor Inspection: The HT7800 provides detailed imaging to identify defects in semiconductor components, which is critical for ensuring product performance and reliability.

- Asbestos Analysis: Labs can use the system to examine the morphology, crystalline structure, and elemental composition of asbestos fibers in both air and bulk samples, supporting regulatory compliance and safety assessments.

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Europe.

For more information on this source, please visit Hitachi High-Tech Europe.