FIB-SEM systems have become essential tools for characterizing and analyzing advanced technologies and high-performance nanoscale materials. As the demand for ultrathin TEM lamellae continues to grow, so does the need for ion and electron optics that can deliver high-quality results without introducing artifacts during FIB processing.

Hitachi’s NX2000 combines high-performance FIB capabilities with high-resolution SEM in a single system. With its unique sample orientation control* and triple beam* technologies, the NX2000 supports high-throughput, high-quality TEM sample preparation, making it a strong choice for today’s most demanding applications.

* Optional

Features

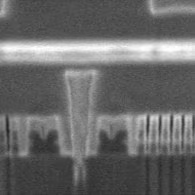

High-contrast, real-time SEM end-point detection enables ultrathin TEM sample preparation for sub-20 nm devices.

- Real-time SEM monitoring during FIB milling

- Sample: NAND flash memory

- Accelerating voltage: 1 kV

- Field of view (FOV): 0.6 µm

Real-time SEM monitoring during FIB milling; Sample: NAND flash memory; Accelerating voltage: 1 kV; FOV: 0.6 µm. Image Credit: Hitachi High-Tech Europe

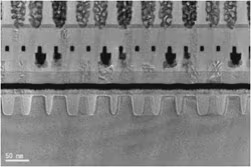

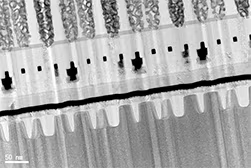

Micro sampling* and a high-precision positioning mechanism* enable precise sample orientation control, supporting Anti-Curtaining Effects (ACE function) and the preparation of uniformly thick lamellae.

With sample orientation control. Image Credit: Hitachi High-Tech Europe

Without sample orientation control. Image Credit: Hitachi High-Tech Europe

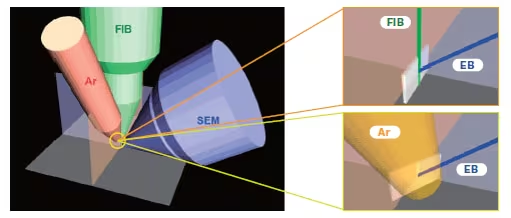

Triple Beam system* Triple beam configuration for Ga FIB-induced damage reduction.

EB: Electron Beam; FIB: Focused Ion Beam; Ar: Argon ion beam. Image Credit: Hitachi High-Tech Europe

Specifications

Source: Hitachi High-Tech Europe

| FIB column |

| Resolution (SIM) |

4 nm @ 30 kV, 60 nm @2 kV |

| Acceleration voltage |

0.5 kV - 30 kV |

| Beam current |

0.05 pA - 100 nA |

| FE-SEM column |

| Resolution |

2.8 nm @ 5 kV, 3.5 nm @ 1 kV |

| Acceleration voltage |

0.5 kV - 30 kV |

| Electron source |

Cold cathode field emission source |

| Detector |

| Standard detector |

Upper/Lower SED & BSED |

| Stage |

X: 0 - 205 mm

Y: 0 - 205 mm

Z: 0 - 10 mm

R: 0 - 360 ° infinite

T: -5 - 60 ° |

Special Accessories (Optional)

- Air protection holder

- Ar/Xe ion 3rd column

- Automatic TEM sample preparation software

- CAD navigation software

- Cooling holder

- Double tilt system

- EDS (Energy Dispersive x-ray Spectroscopy) system

- Linkage software with defect inspection instruments

- Micro-sampling System

- Multi-gas injection system

- Plasma cleaner

- Swing function ( for Ar/Xe ion 3rd column)

- TEM sample preparation wizard

Application Data

Semiconductor

3D Reconstruction from Serial Section SEM Images

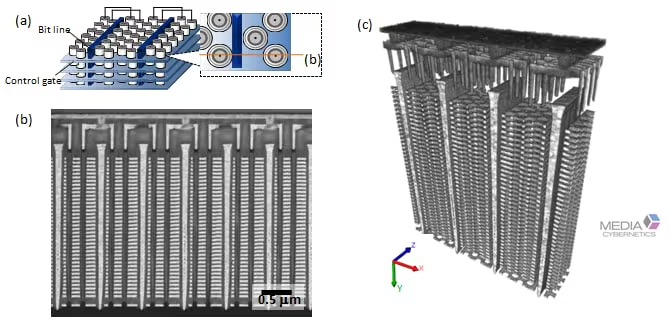

Specimen: 3D NAND flash memory. (a) Schematic view. (b) Cross-sectional BSD image (Accelerating voltage: 2 kV). (c) 3D reconstructed image (Volume rendering). Image Credit: Hitachi High-Tech Europe

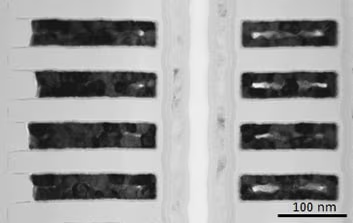

Curtain Effect Free Lamella Preparation Using Double Tilt System

Specimen: 3D NAND flash memory; Observation: HF-3300 Cold FE-TEM (Accelerating voltage: 200 kV). Image Credit: Hitachi High-Tech Europe

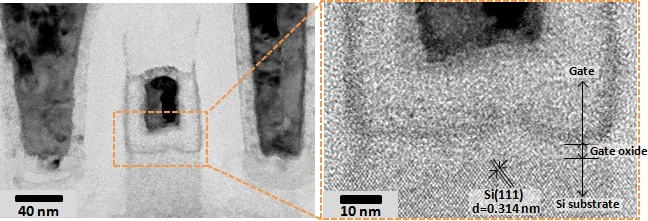

High-Precision Site-Specific Lamella Preparation

Specimen: 22 nm FinFET; Observation: HF-3300 Cold FE-TEM (Accelerating voltage : 200 kV). Image Credit: Hitachi High-Tech Europe

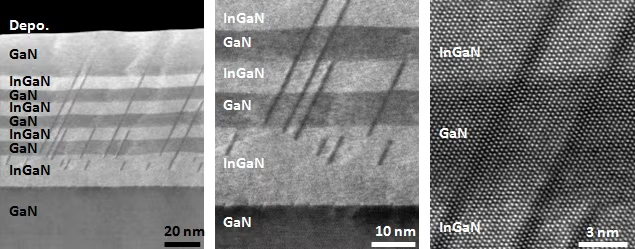

High-Quality Lamella Preparation With In-Situ Ar Ion Milling

Specimen: GaN/InGaN; Final milling: 1 kV Ar; Observation: HD-2700 Aberration -corrected STEM (Accelerating voltage : 200 kV). Image Credit: Hitachi High-Tech Europe

Material Science

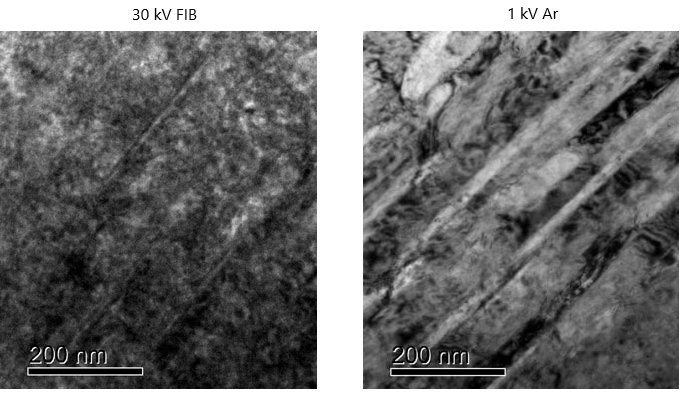

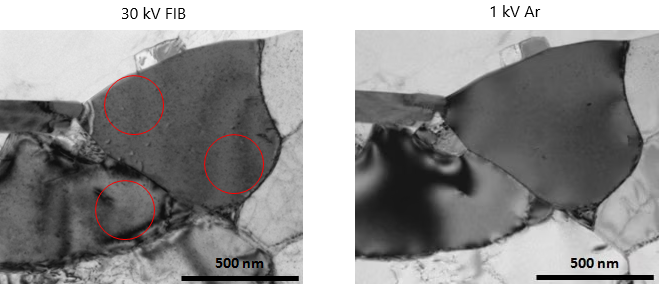

High-Quality Lamella Preparation With In-Situ Ar Ion Milling (1)

Specimen: Zirconium; Observation: HF-3300 cold FE-TEM (Accelerating voltage: 300 kV). Image Credit: Hitachi High-Tech Europe

High-Quality Lamella Preparation With In-Situ Ar Ion Milling (2)

Specimen: Aluminum; Observation: HF-3300 cold FE-TEM (Accelerating voltage: 300 kV). Image Credit: Hitachi High-Tech Europe