The Hitachi IM4000II and ArBlade 5000 ion milling systems deliver high-precision sample preparation for scanning electron microscopy. Suitable for metals, semiconductors, polymers, ceramics, and layered materials, they produce high-quality cross-sections and polished surfaces with minimal artifacts.

Designed for academic research, industrial quality control, and materials science laboratories, both systems provide fast, repeatable results - making them indispensable tools for advanced electron microscopy applications.

- Cross-section & flat milling: Flexible options for different applications

- Cryogenic cooling (optional): Reduces damage to temperature-sensitive samples

- High milling rate: Fast and efficient sample preparation for hard materials

- Optimized for SEM & AFM: Compatible with Hitachi and third-party microscopes

- User-friendly interface: Intuitive touch-screen controls for ease of use

Image Credit: Hitachi High-Tech Europe

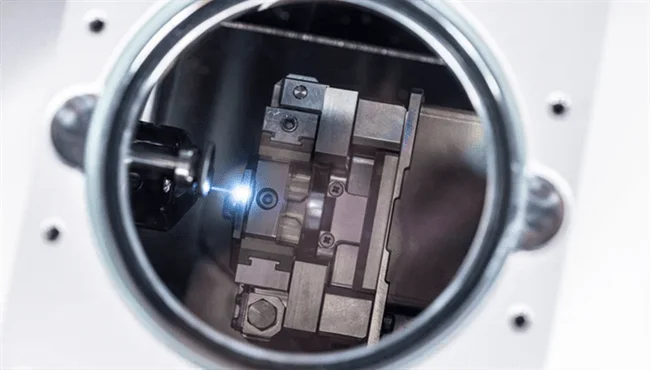

IM4000II

The IM4000II is an all-in-one system capable of both cross-section and flat milling, offering laboratories a flexible and reliable solution for essential sample preparation needs.

Image Credit: Hitachi High-Tech Europe

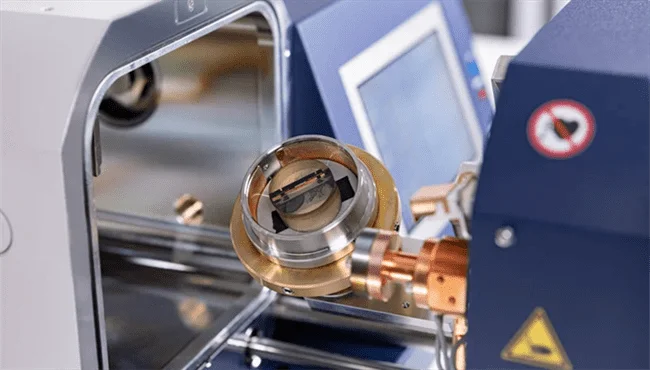

ArBlade 5000

The ArBlade 5000, a more advanced system, offers a higher milling rate and wide-area cross-section milling. It is ideal for demanding applications and laboratories that require high throughput.

Image Credit: Hitachi High-Tech Europe

Features and Benefits

Fast and Precise Milling for a Wide Range of Materials

Reduce turnaround times while maintaining sample integrity.

- The IM4000II delivers a milling rate of 500 µm/hour, while the ArBlade 5000 achieves 1 mm/hour or more (for Si samples with a 100 µm protrusion).

- Both systems are well-suited for hard materials such as metals and semiconductors that require extended milling.

Image Credit: Hitachi High-Tech Europe

Cross-Section and Flat Milling for Flexible Sample Preparation

Get the flexibility to prepare samples the way your work demands.

- Cross-section milling creates smooth, undistorted surfaces without introducing mechanical stress - ideal for studying the internal structures of composite materials, multilayer films, and electronic components.

- Flat milling removes surface artifacts to deliver clean, high-contrast surfaces, making it especially valuable for applications such as EBSD.

Image Credit: Hitachi High-Tech Europe

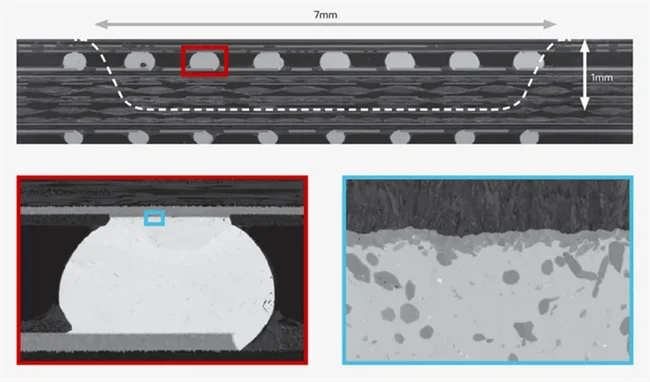

Wide-Area Cross-Section Milling (ArBlade 5000 Only)

Prepare large samples with ease and confidence.

- With milling capability up to 10 mm in width, the system is well-suited for electronic devices and industrial materials.

- It ensures a uniform cross-section across larger samples, enhancing both imaging accuracy and analytical reliability.

Image Credit: Hitachi High-Tech Europe

Cryogenic Cooling for Temperature-Sensitive Samples

Preserve sample integrity for high-resolution imaging.

- The optional Cooling Temperature Control feature for the IM4000II and ArBlade 5000 prevents heat damage to delicate materials such as polymers.

- Maintains a stable temperature range from 0 °C to -100 °C using liquid nitrogen

Image Credit: Hitachi High-Tech Europe

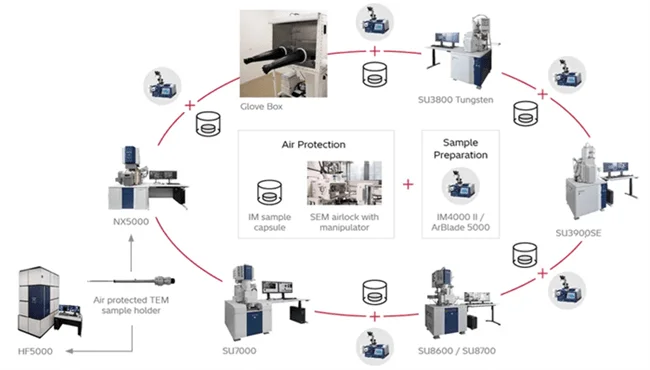

Seamless Integration with Scanning Electron Microscopes (SEMs)

Ensure contamination-free imaging of air-sensitive samples.

- Compatible with Hitachi SEMs and third-party systems for more efficient operations

- The Air Protection Holder Unit (available for both the IM4000II and the ArBlade 5000) allows samples to be transferred to a SEM or AFM without being exposed to air.

Image Credit: Hitachi High-Tech Europe

Applications Gallery

Metals and Alloys

Prepare cross-sections of hard materials for microstructural analysis. Image Credit: Hitachi High-Tech Europe

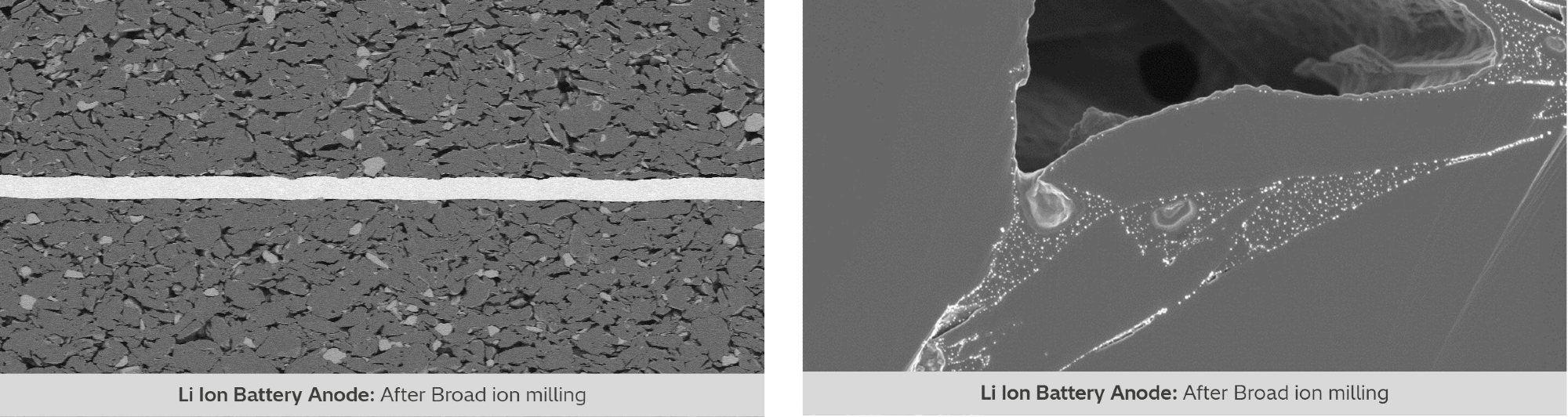

Batteries

Cross-section of Li Ion Battery Anode. Image Credit: Hitachi High-Tech Europe

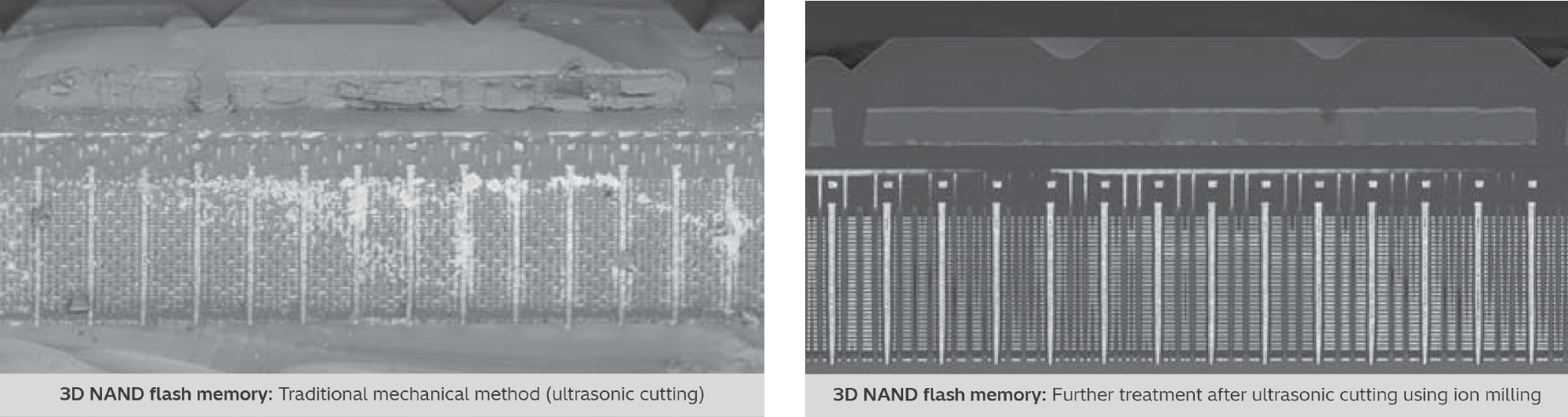

Electronics and Semiconductors

Expose layers and interfaces in integrated circuit. Image Credit: Hitachi High-Tech Europe

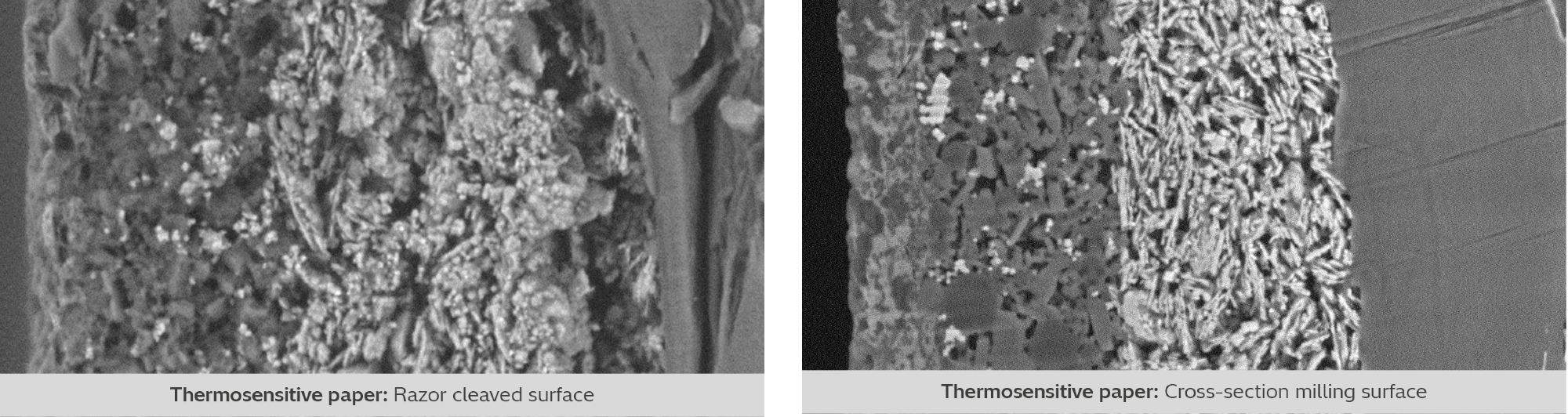

Polymers and Soft Materials

Prevent deformation in temperature-sensitive samples. Image Credit: Hitachi High-Tech Europe

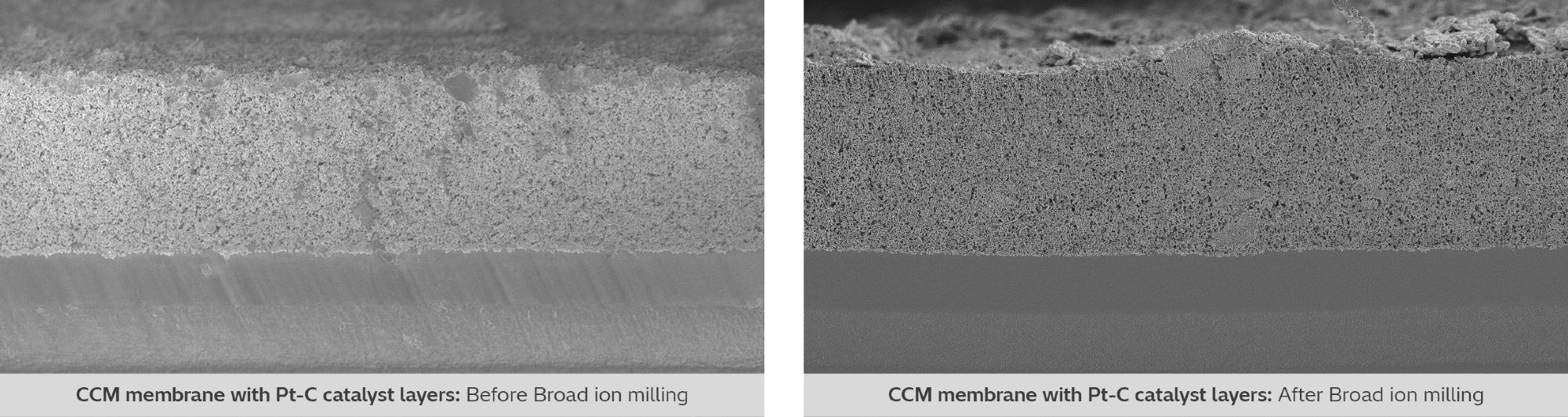

Multilayer Films and Coatings

Study layer composition and adhesion quality. Image Credit: Hitachi High-Tech Europe

Hard Materials

Cross-section milling example. Image Credit: Hitachi High-Tech Europe

Specifications

Source: Hitachi High-Tech Europe

| |

IM4000II |

ArBlade 5000 |

| Gas Used |

Ar (argon) gas |

Ar (argon) gas |

| Accelerating Voltage |

0 to 6 kV |

0 to 8 kV |

| Maximum Milling Rate (estimated for Si samples and 100 μm protrusion) |

500 μm/h or more |

≥ 1 mm/h |

| Maximum Milling Width |

Not available |

10 mm |

| Maximum Specimen Size |

20(W) x 12(D) x 8(H) mm |

20(W) x 12(D) x 8(H) mm |

| Sample Moving Range |

X: ±7 mm, Y: 0 to +3 mm |

X: ±7 mm, Y: 0 to +3 mm |

| Ion Beam Intermittent Irradiation |

ON/OFF setting (1 sec to 59 min 59 sec) |

Standard function |

| Swing angle |

±15 °, ±30 °, ±40 ° |

±15 °, ±30 °, ±40 ° |

| Wide-Area Cross-Section milling |

Not available |

Up to 10 mm width |

| Flat Milling Area |

φ 32 mm |

φ 32 mm |

| Maximum Flat-Milled Sample Size |

φ 50 x 25(H) mm |

φ 50 x 25(H) mm |

| Rotation Speed |

1 rpm, 25 rpm |

1 rpm, 25 rpm |

| Tilt Range |

0 to 90 ° |

0 to 90 ° |

| Cooling Temperature Control (optional) |

0 to -100 °C via LN2 |

0 to -100 °C via LN2 |

| Higher Beam Tolerance Mask (optional) |

2x beam tolerance (Cobalt-free) |

2x beam tolerance (Cobalt-free) |

| Stereo Microscope Unit (optional) |

15x to 100x, Binocular/Trinocular |

15x to 100x, Binocular/Trinocular |