In scanning electron microscopy (SEM), outstanding results begin with outstanding sample preparation.

Image Credit: Hitachi High-Tech Europe

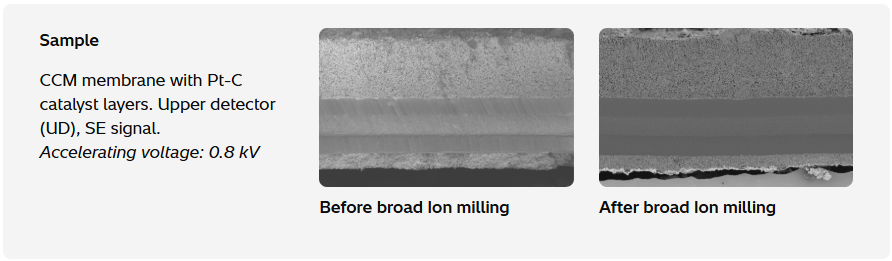

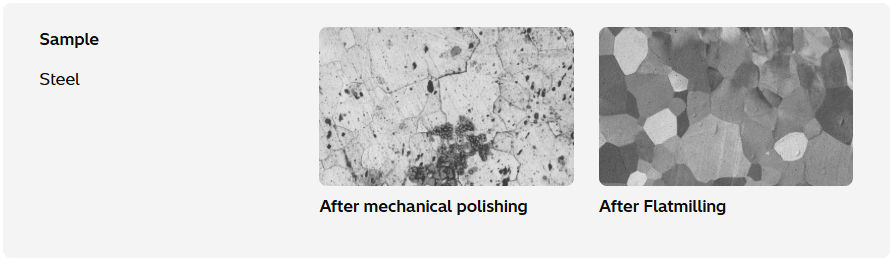

When dealing with delicate structures, mixed-material composites, or complex multilayers, traditional methods like mechanical polishing can fall short, introducing artifacts, surface damage, or thermal stress.

That's why more labs are turning to broad ion beam (BIB) milling using systems like the Hitachi IM4000II and ArBlade 5000. These tools allow for fast, precise, and stress-free cross-sectioning and flat milling across a wide range of materials.

During a recent webinar, attendees put forward various questions about BIB milling and the capabilities of Hitachi's systems. The answers have been compiled here to help you decide whether ion milling is the right solution for your lab.

Image Credit: Hitachi High-Tech Europe

1. Is it necessary to align the sample with the top of the holder during flat milling?

Ideally, yes. The best milling performance is attained when the sample surface coincides with the top of the specimen holder, allowing the beam to impact at the desired coincidence point.

Slight variations are allowed, but excessive offset may affect precision.

2. What are the benefits of BIB milling compared to mechanical polishing?

Broad ion beam milling is contactless, preventing scratches, smearing, and distortion. It is especially useful for samples with hard-soft surfaces, several layers, or fragile structures. You receive clean, flat cross-sections that are ready for SEM, EDS, or EBSD investigation.

3. Can these systems handle fragile or thin samples?

Absolutely. The IM4000II and ArBlade 5000, with characteristics such as intermittent beam pulsing and cryo cooling, are ideal for milling polymers, soft composites, and thin films.

Image Credit: Hitachi High-Tech Europe

4. What are the normal settings for intermittent milling?

A frequent strategy is to turn it on for 10 seconds and then off for 10 seconds. The exact pulse duration can be adjusted according to the sample type and heat sensitivity.

5. How can samples be mounted for cross-section milling to minimize artifacts?

Keep it simple: mount the sample flat, with around 100 µm overlap beneath the mask. Good contact between the mask and the sample is essential for generating a clean, even cross-section.

6. How does cryo chilling affect heat-sensitive materials?

Cryo cooling lowers the temperature of the specimen during milling, which protects delicate materials from thermal damage. It performs extremely well when paired with low acceleration voltage or pulsed beam operation.

7. Is there any risk of re-deposition during milling?

It is uncommon, but if there is a space between the sample and the mask, milled material can redeposit on the surface. Ensure full contact and correct mounting to eliminate this risk.

Image Credit: Hitachi High-Tech Europe

8. What is the difference between conventional and wide-area holders for the ArBlade 5000?

The standard holder accommodates cross-sections up to approximately 1 cm wide. The wide-area holder increases the capacity to up to 4 cm and allows you to mill numerous samples at once, making it suitable for large-scale or comparative analyses.

9. Should I polish my sample before using the ion mill?

Not always. Some samples can be placed directly into the ion milling tool. For others, a mild mechanical polish may be required to maintain flatness. The ion mill can then be used to remove any remaining damage and prepare the finished surface.

10. How can ion milling enhance EBSD preparation?

EBSD requires a completely flat, deformation-free surface. Ion milling achieves this without generating mechanical strain or grain boundary deformation, which are common in mechanically polished samples.

11. Can these systems be applied to cross-section medication granules?

Yes. If embedded in a stable support medium (such as carbon paste), the IM4000II and ArBlade 5000 is able to mill pharmaceutical materials such as medication granules, allowing for a clear view of the interior structure.

Conclusion

Improve your SEM results with Hitachi Ion Milling Systems. Whether your work is in materials science, nanotechnology, or life science, broad ion beam (BIB) milling offers a level of precision and flexibility that traditional preparation methods often can't deliver.

With the Hitachi IM4000II and ArBlade 5000, you can streamline your workflow and produce faster, cleaner, and more consistent results—regardless of how complex your samples may be.

Image Credit: Hitachi High-Tech Europe

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Europe.

For more information on this source, please visit Hitachi High-Tech Europe.