Achieving high-quality imaging in scanning electron microscopy (SEM) relies not only on the capabilities of the microscope but also on the quality of sample preparation.

Image Credit: Hitachi High-Tech Europe

Traditional methods, such as mechanical polishing and chemical etching, can introduce unwanted artifacts, surface damage, or thermal effects that compromise imaging accuracy and detail.

That’s where broad ion beam (BIB) milling makes a difference. Tools like the Hitachi IM4000II and ArBlade 5000 provide a contact-free, high-precision alternative to conventional techniques, enabling clean, artifact-free surfaces for high-resolution SEM imaging.

To help you see how ion milling can improve your SEM workflow, Hitachi has put together answers to some of the most frequently asked questions from researchers and lab professionals.

1. What is the temperature range for the sample surface near the mask during the ion beam polishing process?

There is no built-in temperature sensor for polishing, hence the temperature is largely dependent on the sample. The sample's ability to absorb beam energy is very important. To minimize overheating and melting, the best method is to experiment with different values.

2. Is there a software model to compute or simulate the temperature at the melting point?

No, there is currently no software model for this. The best approach is empirical, which involves modifying settings based on experience and observations. Beam energy, exposure period, and sample heat conductivity all affect temperature.

3. How does cryo-cooling affect heat-sensitive samples?

Cryo-cooling involves cooling the sample holder with liquid nitrogen and monitoring the temperature with a sensor. However, because many heat-sensitive materials are poor thermal conductors, the sample needs additional time to achieve the target temperature.

4. How does BIB milling compare to FIB milling?

It depends on the application. FIB is ideal for precise, small-area cuts (10-20 microns), whereas BIB is faster (up to 100 times faster) and more suitable for preparing large cross-sections. FIB is best for targeting specific locations, whereas BIB is better suited for large-area sample preparation.

5. How does broad ion beam milling compare with plasma FIB?

Plasma FIB is approximately ten times faster than typical gallium FIB, but much slower than broad ion beam milling. For large-scale cross-sectioning, BIB is the more efficient method. Some workflows use laser milling for rough cutting and BIB for fine polishing.

6. Why is a mask required in cross-section milling?

The mask maintains a sharp edge and prevents the beam from striking the sample perpendicularly, resulting in a deep hole rather than a smooth cross-section. The mask material (usually titanium or tungsten carbide) resists sputtering, allowing for controlled erosion.

7. How can heat be managed during ion milling?

Here are a few strategies you can try:

- Lower the acceleration voltage to reduce beam energy

- Use pulsed (intermittent) milling, which gives the sample time to cool between exposures

- Add metal foil around the sample to improve heat conductivity and help distribute heat more evenly

8. Is it possible to combine ion milling with laser processing?

Yes, laser milling is faster, but it results in a rougher surface. Some workflows use laser milling for rough shaping, then BIB for fine polishing and surface refining.

9. What are the benefits of adopting broad ion beam milling over typical mechanical polishing?

BIB milling eliminates surface scratches, embedded debris, and deformation—common issues with mechanical polishing.

Because it’s a contact-free process, it doesn’t introduce mechanical stress, making it especially well-suited for delicate materials such as composites, soft metals, and multilayer structures.

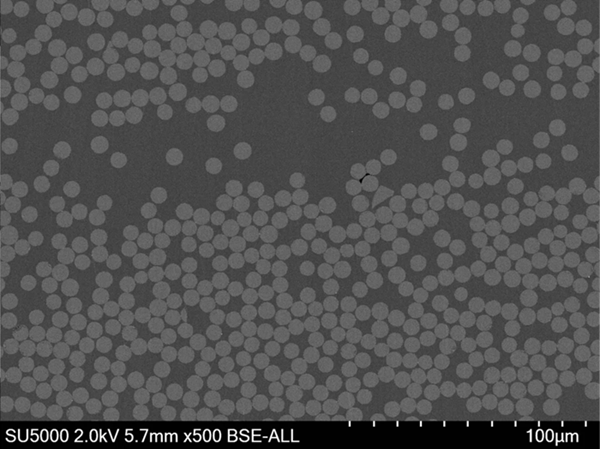

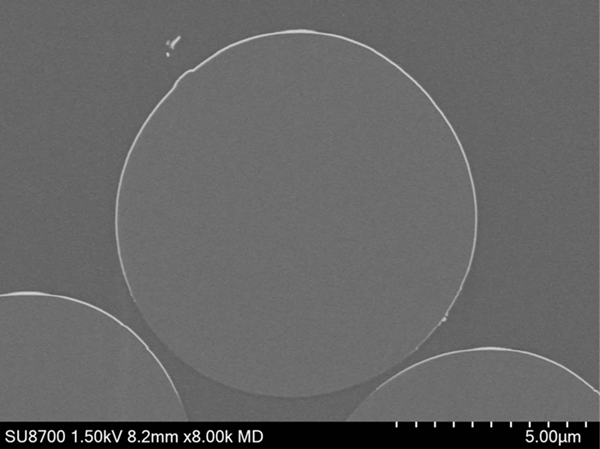

Cross-section BSE image of composite carbon fibers embedded in epoxy. Image Credit: Hitachi High-Tech Europe

Cross-section BSE image of composite carbon fibres embedded in epoxy. Image Credit: Hitachi High-Tech Europe

10. How does the acceleration voltage affect milling speed and surface quality?

- High Voltage (6–8 kV): Enables fast milling but may produce rougher surfaces

- Moderate Voltage (3–5 kV): Offers a good balance between milling speed and surface quality

- Low Voltage (500 V – 2 kV): Slower milling but delivers ultra-smooth surfaces—ideal for applications like EBSD analysis

- Lower Voltages (Below 1 kV): Especially useful for final polishing steps where maximizing surface quality is critical

11. What are the recommended techniques for mounting samples prior to cross-section milling to reduce artifacts?

- Use a flat mounting platform to prevent tilting.

- Minimize mask overhang to ≤100 µm for greater control.

- Use strong, conductive adhesives to prevent the sample from moving.

- Eliminate air gaps between the sample and mask to prevent uneven grinding results.

- Proper mounting creates a clean and well-defined cross-section for SEM investigation.

12. Can the IM4000II and ArBlade 5000 handle thin, sensitive samples without damage?

Yes, features such as low-voltage milling, intermittent beam pulsing, and cryo-cooling enable the safe processing of ultra-thin films, polymers, and delicate specimens without distortion.

13. How might ion beam milling enhance sample preparation for EBSD?

Electron backscatter diffraction (EBSD) requires strain-free and well-polished sample surfaces. Ion beam milling generates a smooth, undistorted surface, resulting in sharper Kikuchi patterns, more precise grain boundary analysis, and higher EBSD indexing success rates. Mechanical polishing can cause deformation.

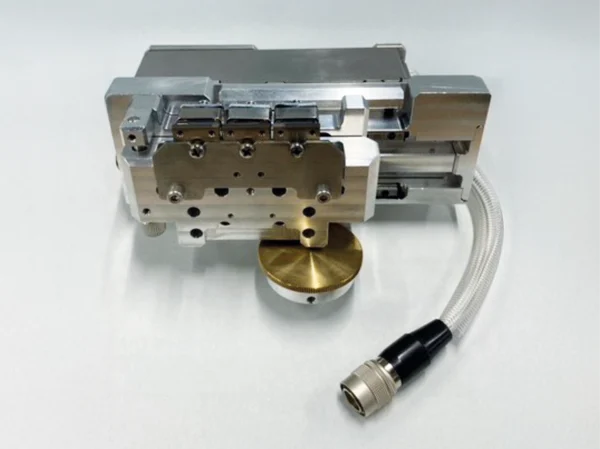

14. What is the difference between utilizing a normal or wide-area cross-section holder in the ArBlade 5000?

- Standard holder supports cross-sections up to 3 mm wide

- Wide-area holder expands milling width up to 10 mm

- Multi-sample holder can handle many samples at once and reach 40 mm width, ideal for large-scale materials investigation

Standard holder. Image Credit: Hitachi High-Tech Europe

Wide-area holder. Image Credit: Hitachi High-Tech Europe

Multi-sample holder. Image Credit: Hitachi High-Tech Europe

15. How does intermittent beam pulsing enhance performance for soft or heat-sensitive materials?

Beam pulsing lowers heat buildup by turning the ion beam on and off. This inhibits:

- Melting and phase shifts in soft materials

- Structural deformation in temperature-sensitive samples

It is especially beneficial for battery separators, polymers, and biological samples.

16. What elements influence curtaining effects, and how can they be minimized?

Curtaining happens when materials of varying hardness degrade at different speeds. To decrease this effect:

- Use swing mode to move the sample slightly while milling

- Optimize acceleration voltage for balanced material removal rates

- Ensure sufficient overhang under the mask for even milling

These modifications ensure flat, consistent cross-sections, even in complex multi-material samples.

Conclusion

Improve your SEM findings with ion milling.

If you use scanning electron microscopy for research, quality control, or failure analysis, sample preparation is equally vital as the microscope itself.

The Hitachi IM4000II and ArBlade 5000 wide ion beam milling systems minimize artifacts, increase surface quality, and provide precise high-resolution imaging without the constraints of standard preparation procedures.

Image Credit: Hitachi High-Tech Europe

This information has been sourced, reviewed and adapted from materials provided by Hitachi High-Tech Europe.

For more information on this source, please visit Hitachi High-Tech Europe.