Sponsored by EntegrisReviewed by Olivia FrostFeb 10 2026

Inkjet inks are colloidal dispersion of color in solution. To avoid sedimentation, instability, or inkjet nozzle failure owing to agglomeration, pigment dispersion must be properly achieved.

When formulating and manufacturing inkjet inks, a reliable method for determining the end product's particle size distribution is required to ensure the ink is of the highest quality.

The Nicomp® dynamic light scattering (DLS) technology can be used to calculate the average size and zeta potential of ink dispersions.

The AccuSizer® single particle optical sizing (SPOS) technology is suitable for assessing whether the finished inkjet ink includes any large particles (tails) that could block jets and reduce performance.

This article provides various examples of how the Nicomp and AccuSizer systems tackle inkjet ink manufacturing difficulties.

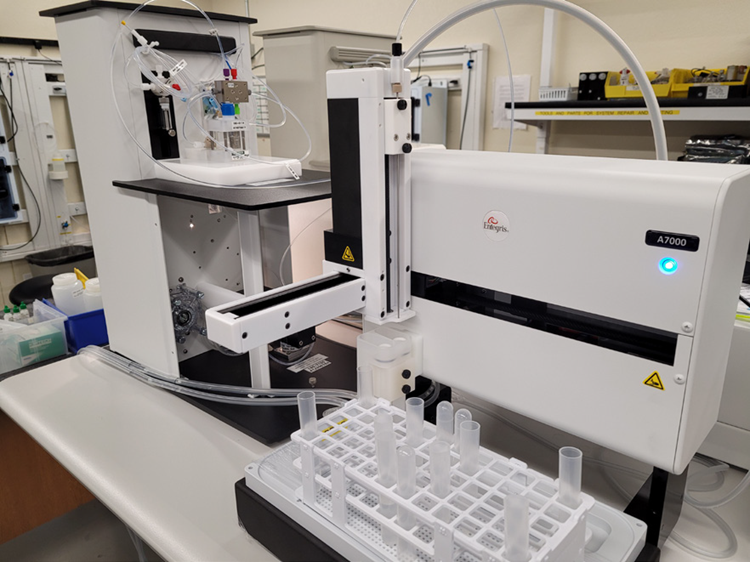

The AccuSizer A7000 APS system. Image Credit: Entegris

Introduction

Pigments used in inkjet inks are typically dispersed to small particle sizes (50-200 nm, depending on the application) and must be colloidally stable.

Colloidal stability can be achieved by either surface modification to produce a sufficient surface charge (zeta potential) or by adsorption of certain chemicals on the surface of pigment particles (steric stabilization).

The size of the pigment particles is crucial because larger particles can clog the jets and channels, potentially damaging the print head. Controlling large particle content (>0.5 - 1.0 µm) requires a strategy sensitive to a limited number of large particles, known as the tail of the distribution.

Particle Sizing and Counting Techniques

Various methods exist for assessing the mean particle size of ink dispersions, including dynamic light scattering (DLS), but often can only detect particles, not small amounts of larger material.

Methods that rely on measuring and counting individual particles are especially well-suited for this type of research, as even minor outliers are measured and counted. The AccuSizer SPOS device is suitable for determining the size and concentration of big particle tails in inkjet inks.

The AccuSizer system combines the LE400 sensor that measures from 0.5-400 µm installed in the APS dilution fluidics and an autosampler that provides automated dilution of the sample to the optimal concentration for the measurement.

Application Example 1: Black Ink Mean Size and Tails

A commercial black inkjet ink sample was tested with DLS to assess the mean size and zeta potential.

The specimen was diluted 1000:1 in deionized (DI) water, and a short test was run to ensure that the size did not change with further dilution.

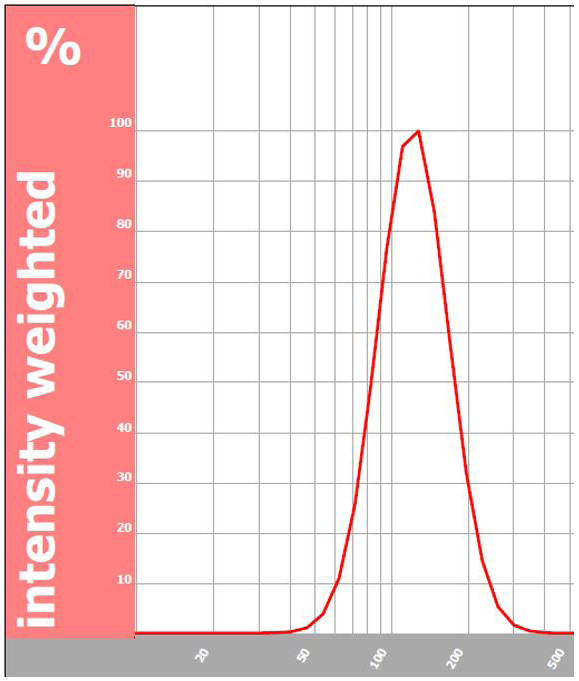

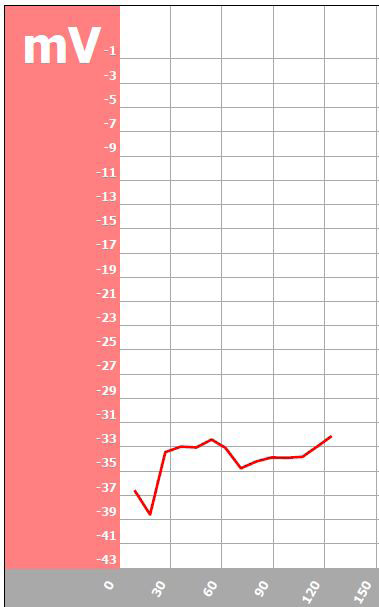

Figures 1 and 2 show the results for the mean size and zeta potential measured using the Nicomp DLS system.

Figure 1. Black ink intensity mean size = 127.49 nm by DLS. Image Credit: Entegris

Figure 2. Black ink zeta potential = -32.1 mV. Image Credit: Entegris

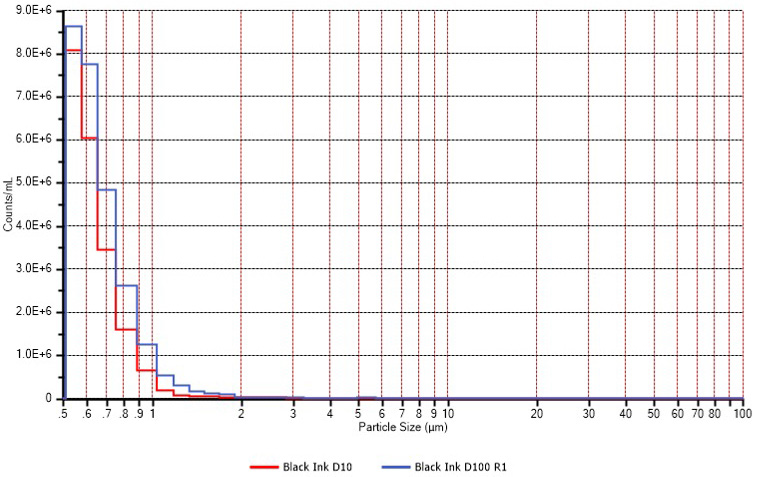

The AccuSizer APS system was used to quantify the big particle tail of more than 0.5 µm. To measure the sample, 100 µL of prediluted 10:1 (D10) and 100:1 (D100) samples were injected directly into the dilution vessel. Single-stage exponential dilution was used.

This method is effective for the initial investigation of unknown samples. Once the right dilution ratio has been calculated, the AccuSizer APS system can use two-stage dilution to maintain an optimal count rate during the test. Figure 3 shows the results for the D10 and D100 samples.

Observe the close agreement between the two dilutions, which validates the AccuSizer instrument's ability to precisely compute back to the original sample concentration.

Figure 3. Black ink tail counts/mL vs. size for D10 and D100. Image Credit: Entegris

Application Example 2: Ink Filtration Study

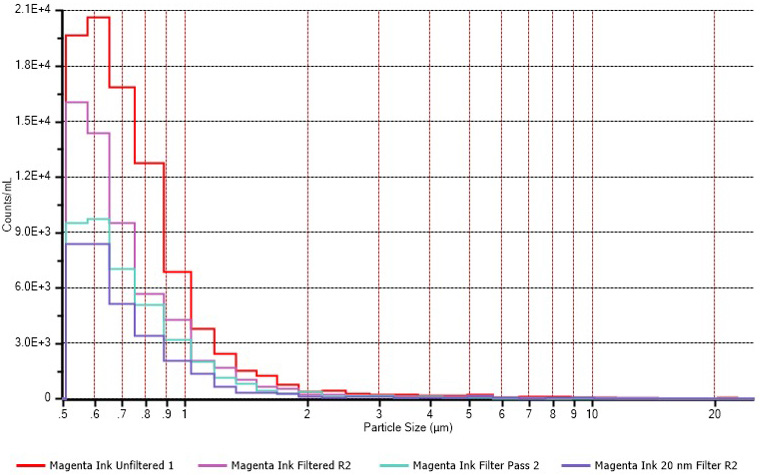

Filtering away big particles ensures that the ink performs properly in the printer. Testing the ink using the AccuSizer SPOS system is the best way to determine the best filtration process. Commercially available magenta and yellow printer ink samples were evaluated prior to and following syringe filtering using the AccuSizer APS system.

Figure 4 displays the particle counts/mL vs. size of the magenta ink sample before filtration, after two passes through a 0.8/0.2 µm two-stage syringe filter, and one pass through a 0.02 µm filter.

Figure 4. Magenta ink before and after filtration. Image Credit: Entegris

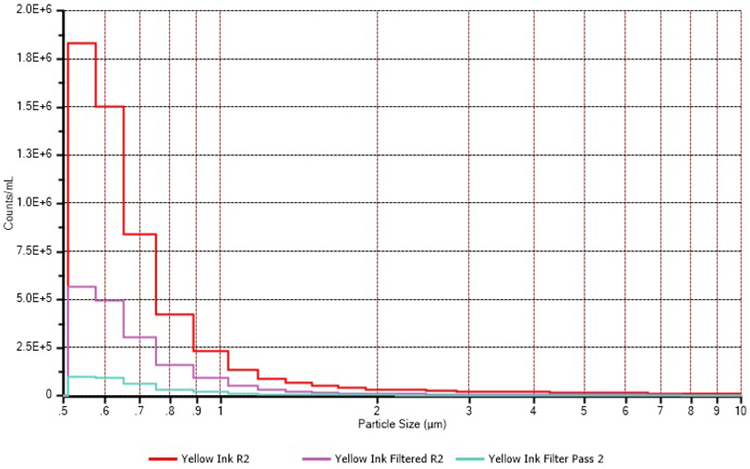

Figure 5 shows the yellow ink sample prior to and following one and two passes through a 0.8/0.2 two-stage syringe filter.

Figure 5. Yellow ink before and after filtration. Image Credit: Entegris

Automation

Figure 6 shows how the Nicomp DLS system and the AccuSizer SPOS system can be connected to an autosampler for high sample throughput requirements.

Different concentrations, run periods, and flow rates can be examined in the same sample tray using separate measurement techniques for each sample. Data management is simplified with automated reporting and the ability to export results to Excel.

Figure 6. AccuSizer APS system (left) and autosampler (right). Image Credit: Entegris

Conclusions

Entegris supplies a variety of methods for particle characterization of inkjet printer inks. The Nicomp DLS system allows for the analysis of mean particle size and zeta potential.

The AccuSizer SPOS device is perfect for measuring the size and concentration of big particle tails in inkjet inks. The effect of filtering was explored in this document; however, the system can be utilized as a general quality assurance tool as well as a process development tool to investigate optimal process settings.

Coupling either system to the autosampler meets high sample-throughput requirements. Entegris field application professionals offer installation and calibration assistance worldwide.

This information has been sourced, reviewed, and adapted from materials provided by Entegris.

For more information on this source, please visit Entegris.