In the last decade, there has been an increased focus on real-time monitoring and the utilization of advanced sensing mechanisms in industrial applications. The nano-sensor market has seen significant growth, with experts employing these sensors for various purposes, including in medicine and ecological monitoring.1 This article highlights key developments in the global nano-sensor market.

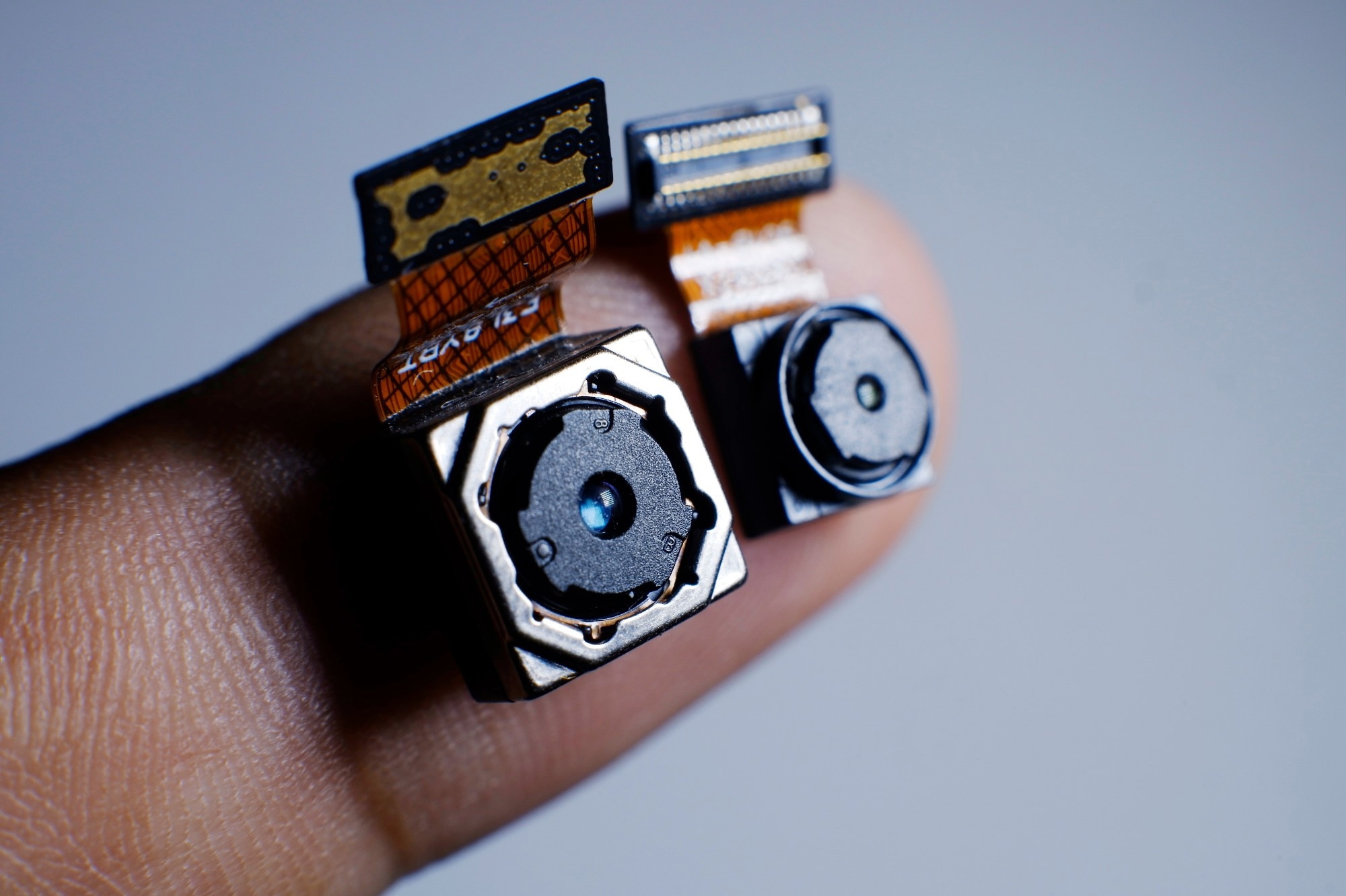

Image Credit: jarpict/Shutterstock.com

What Are Nano-Sensors?

Nano-sensors are devices that use nanotechnology to detect, measure, and respond to specific physical, chemical, or biological changes in the targeted environment at the nanoscale.2

These highly sensitive sensors have at least one dimension under 100 nm and convert nanoscale information into data for analysis. A nano-sensor typically consists of a sensor, analyte, transducer, and detector. They often operate by monitoring electrical changes in the sensor material.3

Current Market Trends

The nano-sensor market has experienced substantial financial and economic growth globally. Recent reports estimate its value between $637 million and $700 million.

With increasing demand for nano-sensors in the biomedical, ecological, chemical, and electronics industries, experts forecast an average return on investment in the nano-sensor industry of 7 % to 11 %. By 2032, the market is expected to be valued at approximately $2.37 billion to $3.1 billion.4, 5

Recent market surveys indicate that electrochemical nano-sensors are the preferred choice among healthcare professionals, with the healthcare sector accounting for approximately 25 % of the total market share.

The North American region has made significant investments in developing novel and efficient nano-sensors, particularly in integrating these sensors with the Internet of Things (IoT). This focus has positioned North America as a leader in research and development within the nano-sensor field.6

Europe is also heavily investing in nano-sensor research, with companies expected to grow at around 6 % over the next eight years. Initiatives like SUSANO aim to enhance efficiency and innovation, particularly in the field of sustainable nano-sensors.

This project, initiated at the Universiteti i Tiranes (UT), focuses on sustainable nano-sensor manufacturing specifically for the detection of water pollutants, reflecting the commitment of European researchers, companies, and governments to excel in nano-sensor fabrication.7

Trends in Biomedical and Environmental Protection Sectors

Recent advancements in nanomedicine and nanodiagnostics have significantly improved healthcare outcomes. The application of novel nanomaterials in nano-sensors has facilitated the development of submicron-sized nano-biosensors, ideal for intracellular use.

The Nano-biosensor market is projected to reach $798.41 million by 2030, with a compound annual growth rate (CAGR) of 10.60 %. The rapid commercialization of this technology, along with university spin-out businesses, plays a crucial role in advancing this field.8

Environmental monitoring also heavily relies on nano-sensors. The healthcare sector generated around $2.27 million from nano-sensor applications in 2023, while the global environmental monitoring market is expected to reach $3.93 billion by 2032.9

Companies like Nasys and Agilent Technologies are at the forefront of developing nano-sensors optimized for pollutant monitoring, ensuring continued growth in this industry.

Technological Advancements

Measuring intracellular pH is crucial for diagnosing various diseases, including carcinomas. Traditional pH-sensitive nano-sensors, such as those based on silica and quantum dots, may pose environmental risks.

Recently, a new generation of pH-responsive nano-sensors has been developed using alginate natural polymers and pH-sensitive fluorophores through an eco-friendly, solvent-free method.

These alginate-based pH nano-sensors exhibit low mean hydrodynamic diameters (MHD) and acceptable polydispersity indices (PDI), making them viable alternatives to conventional sensors for detecting pH in biological systems.10

Additionally, significant progress has been made in selecting nanomaterials for nano-sensor fabrication. Researchers have recently employed fuzzy neural networks to create a decision-making framework for material selection, utilizing Dombi t-norm and t-conorm operations, which are integral to fuzzy neural networks. This framework allows experts to identify the most suitable nanomaterial for nano-sensor production.11

Challenges in the Nano-Sensor Industry

Fabricating and deploying nano-sensors presents several challenges. The demand for high-precision nano-sensors is increasing, yet the manufacturing of these intricate devices is time-consuming, expensive, and requires specialized instruments.

Nanostructures are highly sensitive to small variations in the manufacturing process, complicating efforts to achieve uniformity and consistency in mass production. Another significant concern is sensor stability. The variable environments in which nano-sensors operate, characterized by fluctuations in pressure and temperature, can impact their structural integrity and performance.

Addressing these challenges necessitates the use of advanced methods and innovative materials to ensure the longevity and stability of these devices.12

The growing demand for nano-sensors has attracted substantial investment from governments and companies worldwide. These initiatives are leading to developments such as the integration of AI for material selection and the creation of sustainable nano-sensors.

Despite the challenges, the key statistics indicate robust growth and revenue generation in the nano-sensor industry, securing their role in future industrial applications.

Discover More: Using Pressure Sensors to Improve Unmanned Aerial Vehicle (UAV) Speed and Altitude

References and Further Reading

- Yang, T., et al. (2021). Challenges and potential solutions for nanosensors intended for use with foods. Nat. Nanotechnol. https://doi.org/10.1038/s41565-021-00867-7

- Khazaei, M., et al. (2023). Nanosensors and their applications in early diagnosis of cancer. Sensing and Bio-Sensing Research. https://doi.org/10.1016/j.sbsr.2023.100569

- Javaid, M., et al. (2021). Exploring the potential of nanosensors: A brief overview. Sensors International. https://doi.org/10.1016/j.sintl.2021.100130

- Research Nester. (2024). Nanosensor Market Size & Share, By Type; Application - Global Supply & Demand Analysis, Growth Forecasts, Statistics Report 2024-2036. [Online] Nanosensors Market. Available at: https://www.researchnester.com/reports/nanosensors-market/3083

(Accessed on: September 24, 2024).

- Global Market Insights. (2024). Nanosensor Market - By Type (Optical Nanosensor, Chemical Nanosensor, Physical Nanosensor), By Technology (Molecular Self Assembly, Top-down Assembly, Bottom-up Assembly), By End User & Forecast, 2024 - 2032. [Online] Global Market Insights. Available at: https://www.gminsights.com/industry-analysis/nanosensor-market (Accessed on: September 24, 2024).

- Market.us (2024). Nanosensors Market: Pioneering Precision in Tomorrow's Technology. [Online] LinkedIn. Available at: https://www.linkedin.com/pulse/nanosensors-market-pioneering-precision-tomorrows-technology-fd97c (Accessed on: September 25, 2024).

- SUSANO. (2024). Twinning to Boost the Scientific and Innovation Capacity of the University I Tiranes to Develop Sustainable Nano-sensors For Water Pollution Detection. Funded by the European Union. [Online] SUSANO. Available at: https://www.susnano.eu (Accessed on: September 25, 2024).

- Ulucan-Karnak, F. et al. (2024). Commercial roadmap of nanobiosensor development. Frontiers in Nanotechnology. https://doi.org/10.3389/fnano.2024.1348308

- Sterling, I. (2024). The Market Growth of Nanosensors in Healthcare and Environmental Monitoring. [Online] Nano Magazine. Available at: https://nano-magazine.com/news/2024/1/29/ztq0mrp345s9nfh48hekpbej9kk7lc (Accessed on: September 25, 2024).

- Alwraikat A., et al. (2023). Development of a Novel, Ecologically Friendly Generation of pH-Responsive Alginate Nanosensors: Synthesis, Calibration, and Characterisation. Sensors. https://doi.org/10.3390/s23208453

- Abosuliman, S., et al. (2024). Using a fuzzy credibility neural network to select nanomaterials for nanosensors. Engineering Applications of Artificial Intelligence. https://doi.org/10.1016/j.engappai.2024.108958

- MPScholar. (2024). Nano-Sensor and Miniaturization. [Online] MPScholar. Available at: https://www.monolithicpower.com/en/learning/mpscholar/sensors/future-trends-and-innovations-in-sensing/nano-sensor-and-miniaturization?srsltid=AfmBOoqQoDb7E6Za4NDvVO5FzNbfQrRwicgAN-h_U-kXucw3ZVVnsKPG (Accessed on: September 26, 2024).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.