Oct 15 2008

In the framework of Holst Centre, IMEC achieved a new record for micromachined piezoelectric energy harvesters, now delivering an output power of 60µW. The harvester can be realized with a simple, low-cost CMOS-compatible production process by using aluminum nitride (AlN) as piezoelectric material. The low resonance frequency of only 500Hz makes the device widely applicable. The output power of 60µW is sufficient to drive simple wireless sensors that intermittently transfer sensor readings to a master. Potential applications include tire pressure monitoring systems (TPMS) or monitoring of industrial equipment.

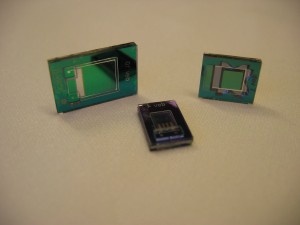

Piezoelectric energy harvesters.

Piezoelectric energy harvesters.

Energy harvesters convert ambient energy - light, heat, or vibrations - into electricity. They are indispensible in situations where batteries cannot be replaced easily. Examples are autonomous sensor networks that are distributed over large areas and in locations that are difficult to access. IMEC's new energy harvester is a micromachined device converting vibration energy through a piezoelectric transducer. It can be used to generate energy for sensors in, for example, planes, vehicles, or vibrating industrial equipment.

For the new harvester, an experimental output power of 60µW was measured with an input acceleration of 2g at a resonance frequency of 500Hz. It consists of a piezoelectric capacitor formed by a Pt electrode, an AlN piezoelectric layer and a top Al electrode. The capacitor is fabricated on a cantilever which has a mass on its tip. When the harvester vibrates, the mass on the cantilever causes the piezoelectric layer to be stretched, inducing an electrical power. The use of AlN as piezoelectric material makes the device compatible with CMOS processes, allowing production at a lower cost.

Last year, IMEC already showcased a piezoelectric harvester with a reported 40µW output power. But this device had a piezoelectric layer fabricated with PZT. The current AlN layer has the advantage that it can be made in a simpler deposition process. Moreover, the PZT device operated at 1.8kHz. The lower resonance frequency of the new harvester - 500 Hz - corresponds with vibration frequencies in, for example, industrial equipment or car tires. This greatly enlarges the field of application for this harvester.