Sponsored by Park SystemsReviewed by Olivia FrostJun 11 2025

This article introduces Park Systems' latest large-sample atomic force microscope (AFM), the FX200—engineered to support both foundational studies and advanced research applications.

Designed for versatility, the FX200 accommodates a wide range of sample types and sizes, making it an ideal solution for researchers in academia and industry pursuing high-impact discoveries and innovations.

Introduction

Atomic Force Microscopy (AFM) has become an essential tool in nanoscale surface characterization due to its high spatial resolution, non-destructive nature, and adaptability across a wide range of materials.

It is widely used in domains such as materials science, semiconductor research, and polymer analysis, providing essential insights into surface shape, mechanical properties, and functional qualities on the nanoscale.

Despite its benefits, traditional AFM operation poses substantial problems, owing to the requirement for manual involvement in critical operations such as probe exchange, cantilever detection, laser beam alignment, and parameter adjustment.

These stages necessitate a high level of knowledge and a significant amount of time to complete correctly, frequently resulting in discrepancies in measurement reliability and limiting throughput in high-volume research settings.

Overcoming operational hurdles is critical to the growth of AFM technology.

The future of AFM also depends on the development of enhanced automation capabilities that simplify procedures while maintaining accuracy. Researchers should be able to collect high-quality, reproducible data with minimal manual effort, allowing them to concentrate on data analysis rather than complicated setup processes.

Park Systems' FX product line embraces this goal by incorporating cutting-edge automation, including completely automated probe exchange, real-time cantilever detection, and intelligent laser beam alignment.

By dramatically eliminating user intervention and potential sources of error, the FX series improves measurement efficiency and reliability, ushering in a new era of user-friendly, high-performance AFM systems that allow users to concentrate completely on their research.

FX200 inherits these benefits while also offering an excellent option for large-scale wafer-level measurements. It is equipped with Macro Optics, an off-axis sample view camera, which allows researchers to capture a full image of the entire sample at a glance, making the precise selection of measurement areas simple.

The FX series' automation capabilities are enhanced with modern technologies like StepScan™, which allows for programmable recipe-based measurements.

These functionalities enable researchers to select measurement points, specify parameters, and construct repeated scans based on their experimental requirements, considerably boosting workflow efficiency and reproducibility.

FX200 redefines high-throughput, precision AFM measurements with its seamless integration of automation and user control, ranging from small samples to 200-mm wafer examination.

One of Park Systems' favorite user quotes is "If AFM had been known to be this easy, it would have been used much more often in most of my samples."

While supporting users of the FX product line, Park Systems quickly recognized a broader need: to equip researchers with robust tools for comprehensive record-keeping and experimental archiving. These capabilities not only streamline the process of collecting scientific data but also provide a reliable, error-free digital lab bookkeeping system.

The following sections outline how these needs have been effectively addressed.

Overview of FX200

The FX200 is Park Systems’ latest large-sample atomic force microscope (AFM), designed to support advanced research with enhanced automation, broad sample compatibility, and improved performance (Figure 1).

What distinguishes the FX200 from other large-sample AFMs is its accessibility—it delivers high-quality results for both AFM experts and non-experts alike. It achieves high precision without compromising speed, striking an effective balance between performance and efficiency. This ease of use is built on decades of experience in developing automation and intuitive software for industrial in-line inspection AFMs.

The FX200 accommodates a wide range of sample sizes, from small specimens to full 200 mm wafers. Optical microscopy enables users to inspect and navigate the sample surface easily, and measurement positions can be saved with just a few clicks, making it simple to repeat scans at the same or multiple locations.

Figure 1. The full shot of FX200. The AFM system is located in an acoustic enclosure to minimize various noises. Image Credit: Park Systems

Key Features 1. Effortless Setup: AFM Probe Handling and Beam Alignment

A standout feature of the FX series is its automated probe reading and exchange system, combined with automatic beam alignment. These capabilities greatly simplify the setup process, which is traditionally one of the more challenging aspects of AFM measurements.

With just a few clicks, researchers can bypass these barriers, making the technique far more accessible, even for those new to AFM.

The FX200 supports up to 16 AFM probes, enabling long-duration measurements on large samples without manual intervention. Each probe is identified via a QR code, allowing users to quickly view the loaded probe types. When a specific probe is selected, the FX200 automatically retrieves it, verifies the cantilever position, aligns the laser beam, and performs the frequency sweep, all with minimal user input.

Beyond user convenience, this automated tip exchange delivers significant time and cost savings. The risk of damaging expensive probes, especially by less experienced users, is virtually eliminated, helping reduce unnecessary consumable costs.

Training time is also minimized, as users no longer need to learn the intricate and time-consuming steps of manual probe mounting. Traditional setup tasks, such as aligning the laser and positioning the cantilever over the photodetector (PSPD), are handled automatically.

By streamlining these processes, the FX200 enhances efficiency, ensures repeatable results, and lowers the entry barrier for high-precision AFM. The result is a powerful yet accessible platform for nanoscale analysis.

Key Features 2. Improved Sample Navigation Optics with Large Field-of-View Camera

The FX200's sample chuck, which can accommodate samples ranging from less than a coupon to a 200 mm wafer, along with the broad field-of-view camera, allows for quick and straightforward region of interest identification.

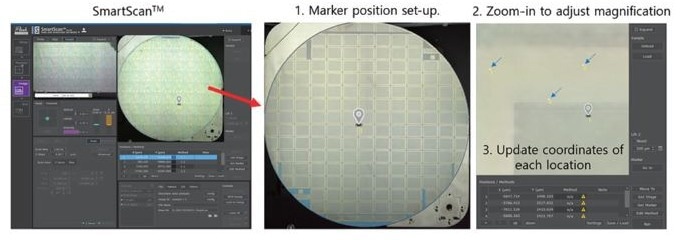

As shown in Figure 2, SmartScan™—Park Systems' AFM operating software—offers a comprehensive view of the sample's entire structure. To use it, follow these steps:

- Use the Marker tool to identify the approximate measurement location.

- Use the mouse scroll to zoom in and select the precise spot for measurement.

In this example, the FX series’ enhanced optical vision enables visualization down to a 0.87 μm line width, enhancing the overall measurement experience.

3) All positions marked for multiple measurements are automatically recorded as coordinates, allowing for easy repeatability and accurate documentation.

Figure 2. Macro optics for full 200 mm sample view. Image Credit: Park Systems

The multi-sample chuck, which can hold up to 16 coupon-sized samples, allows for comparative measurement by uploading samples from many circumstances at once.

When combined with the FX200's automatic probe exchange capability, this functionality simplifies the measuring process for researchers. In addition, each sample is securely bonded to the sample chuck under vacuum conditions, reducing any damage.

Key Features 3. StepScan: How is Automation Utilized in AFM?

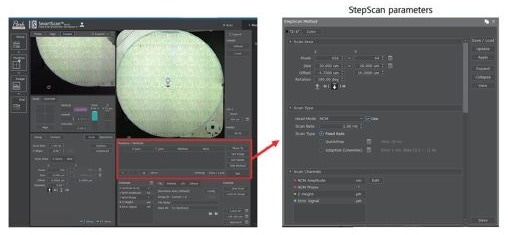

The FX200’s automation features play a key role in enhancing the user experience by making the system easier to operate. StepScan enables straightforward automation of repetitive measurements, making it ideal for both research and industrial applications.

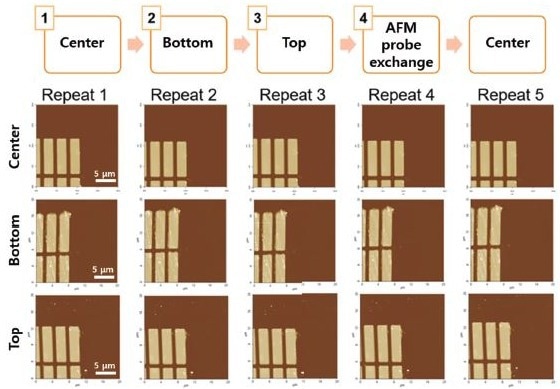

With StepScan, users can perform measurements at multiple positions under identical or varying conditions. As shown in Figure 3, once measurement positions and parameters are set and initiated, the system can automatically carry out repeated scans across those positions, even while exchanging AFM probes, as demonstrated in Figure 4.

Figure 3. Captured SmartScan™ for StepScan and its parameters. Automatic sequential measurements at multiple predefined coordinates are possible by StepScan. Image Credit: Park Systems

Figure 4. Repeated AFM results of each wafer position. Using StepScan, the center, bottom, and top positions of a 200 mm wafer are measured sequentially; following an AFM probe exchange, the process is repeated. Feature position across the wafer shows repeatability of ±2 μm. Image Credit: Park Systems

Key Features 4. From Large to Small

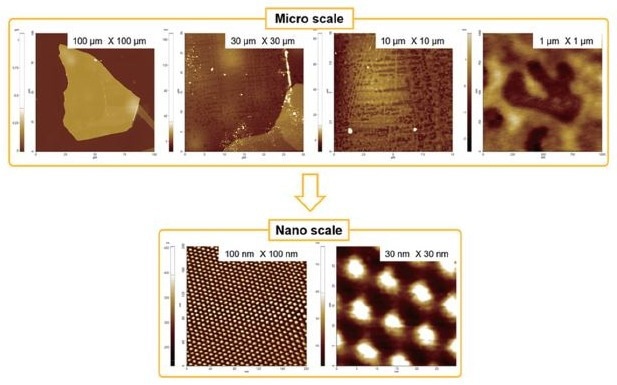

User-friendliness and ease of use are essential, but at the heart of AFM is its ability to deliver accurate results and high performance. The FX200 stands out in this regard, capturing surface structures across a broad range of scales, from wide-area scans of 100 μm × 100 μm down to detailed nanoscale features.

As shown in Figure 5, the system can progressively zoom in from the overall shape of a graphene flake layer to reveal its fine structural details. Notably, the moiré pattern in twisted bilayer graphene is clearly imaged at scan sizes of 100 nm × 100 nm or smaller, demonstrating the FX200’s precision and resolution capabilities.

Figure 5. AFM results from 100 μm×100 μm to 30 nm×30 nm scan size. It covers a wide range of scan sizes from the entire structure of a graphene flake to the moiré pattern of twisted bilayer graphene. Image Credit: Park Systems

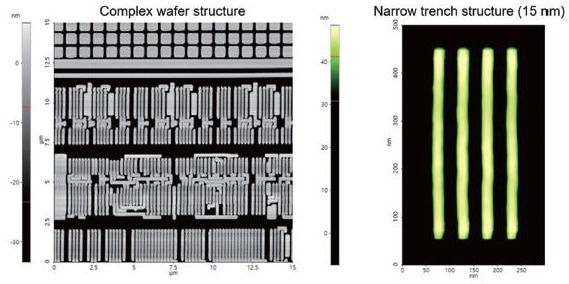

While the FX200 is built for large-sample analysis, researchers often need to investigate extremely small features. To meet this need, the FX200 captures nanoscale structures within small scan areas while preserving the integrity of complex structures across larger areas, as illustrated in Figure 6.

Figure 6. AFM results of Si wafer. It is possible to accurately measure the complex structure of Si wafer or the tiny and narrow trench structure. Image Credit: Park Systems

Key Features 5. Equipment Management

The FX200 is designed for a wide range of users, including academic and industrial labs, as well as shared user facilities, ensuring consistent performance and safety across diverse environments.

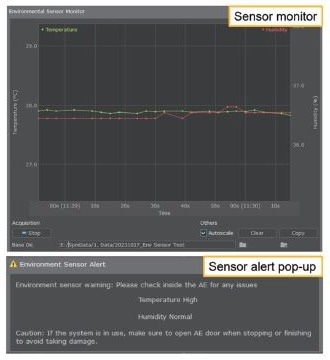

To support reliable operation, the system continuously monitors real-time environmental conditions using a temperature and humidity sensor positioned near the AFM head. These values are displayed as a plot chart (Figure 7), and if they fall outside the specified range (temperature: 18 °C to 40 °C / humidity: 30 % to 60 %), an alert pop-up notifies the user.

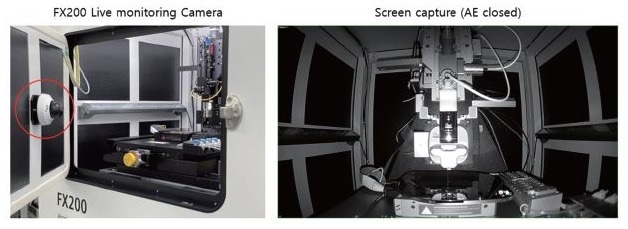

The FX200 prioritizes ease of use, eliminating the need for researchers to frequently open and close the acoustic enclosure (AE) to check the system.

A live monitoring camera installed inside the AE allows real-time observation of the AFM system and the internal environment during measurements (Figure 8). This feature enables users to monitor system status without interrupting the experiment, ensuring continuous operation while improving convenience and reliability in high-precision AFM workflows.

Figure 7. Captured SmartScan™ for environment monitoring. Changes in real-time temperature and humidity can be checked with plot charts, and if it is out of the designated range, the researcher is informed by alert pop-up. Image Credit: Park Systems

Figure 8. Live monitoring camera. A live monitoring camera enables real-time observation of the inside of AE. Image Credit: Park Systems

Conclusions

Advancements in AFM technology have significantly transformed surface characterization across a wide range of disciplines.

With its unique capabilities, AFM has driven progress in academic research and has become essential to numerous industrial applications. As technology continues to evolve, AFM's role is set to grow even further, underscoring its lasting importance in both scientific and industrial settings.

Park Systems’ development of the FX200 reflects a strong commitment to enabling the next generation of research.

With its automated probe exchange system, the FX200 offers exceptional convenience, improving productivity while maintaining reliable performance and safety. Equipped with state-of-the-art Park AFM technology and advanced automation, the FX200 sets a new standard for atomic force microscopy in shared user facilities and industrial laboratories.

This information has been sourced, reviewed and adapted from materials provided by Park Systems.

For more information on this source, please visit Park Systems.