Sponsored by Park SystemsReviewed by Olivia FrostJan 28 2026

In-situ monitoring and control of etching processes are critical components in the micro- and nano-structuring of materials and thin films.

Traditional techniques primarily encompass laser end-point detection and optical spectrometry. While both methods can monitor the thickness or composition of etched layers and materials, they cannot offer in-situ, three-dimensional topography measurements of the etching process with sub-micron lateral resolution.

Conversely, conventional optical and mechanical profilometers are scanning-based methods that provide static 3D topography measurements. The innovative DHM® non-scanning imaging technology enables users to record sequences of real-time 3D topographies at camera rate, achieving interferometric vertical resolution.

DHM® is capable of performing measurements through both glass and liquids, thereby facilitating in-situ assessments across various environmental conditions. This capability can also be applied to both dry and plasma etching processes.

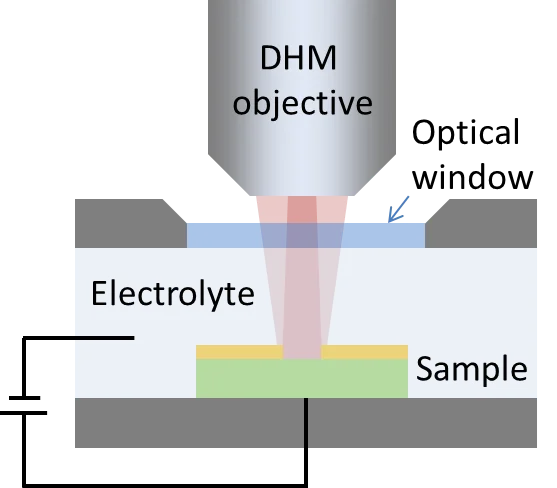

In this regard, a metallic sample coated with polymer resist is patterned with trenches of varying widths and submerged in a liquid electrolyte where an electric current is applied to initiate electrochemical etching. Measurements are conducted through the transparent window of the etching chamber, allowing DHM® to monitor etching depth and surface roughness in situ.

Schematic setup of in situ etching monitoring through optical window by DHM®. Image Credit: Park Systems

In situ monitoring of electrochemical etching of 20 um and 100 um trenches. Image Credit: Park Systems

In situ monitoring of electrochemical etching of 300 µm trenches. Image Credit: Park Systems

This information has been sourced, reviewed, and adapted from materials provided by Park Systems.

For more information on this source, please visit Park Systems.