Scientists at the Lawrence Berkeley National Laboratory (Berkeley Lab) of the U.S. Department of Energy (DOE) have studied the function of temperature in manipulating a nanofabrication technique known as dip-pen nanolithography for writing chemical patterns down to 20 nm.

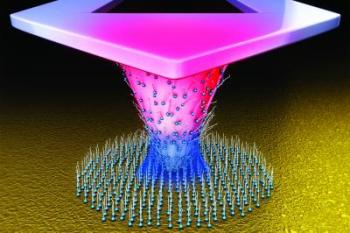

Thermal dip-pen nanolithography turns the tip of scanning probe microscope into a tiny soldering iron that can be used to draw chemical patterns as small as 20 nanometers on surfaces. Credit: Image courtesy of DeYoreo, et. Al

Thermal dip-pen nanolithography turns the tip of scanning probe microscope into a tiny soldering iron that can be used to draw chemical patterns as small as 20 nanometers on surfaces. Credit: Image courtesy of DeYoreo, et. Al

The dip-pen nanolithography is economical and quickly developing and patterning several materials on surfaces to make chemical sensors and electrical circuits. It can also be used to study the bonding of pharmaceuticals to viruses and proteins. It can draw numerous chemical compounds in virtually all environments. Its cousin technique known as thermal dip-pen nanolithography makes this technique to be used in solid materials by converting an atomic force microscope tip into a small soldering iron.

The drawing tip can also function as a surface profiler, enabling the imaging of a newly-written surface directly after patterning at nanoscale accuracy. During the study, the scientists thoroughly studied the impact of temperature on the size of the feature. Utilizing the findings of the study, the researchers designed a unique model to describe different stages of ink molecules, which include their journey from the drawing tip to the substrate, assembling into an aligned layer and development into a nanoscale structure.

Scientists at the University of Illinois at Urbana-Champaign, a specialist in producing innovative tips for atomic force microscopes, also partnered in the study. They have designed an atomic force microscope tip based on silicon with charge-carrying atoms sprayed into the silicon in such a manner that a fewer reside at the tip, while large number of atoms stays at the base. This enables the tip to be heated up similar to an electric stove’s burner during the passage of electricity.

Inks applied on the tip are then heated up by this ‘nanoheater’, which makes the inks to travel to the surface for producing micro-sized and nano-sized features. The size of the feature varies with the hotness of the tip. The researchers used this technique to draw lines and dots of mercaptohexadecanoic acid over gold surfaces.