The Zeta-20 Optical Profiler is an ideal instrument (Figure 1) for edge inspection and metrology, with superior features such as XOD inspection, edge defect review edge trim step height and X-Y-è shift. It is a non-contact 3D optical profiler with an inspection option.

Figure 1. The Zeta-20 Optical Profiler with 200/300mm EFEM and automated s/w for Edge Inspection and 3D Metrology with full wafer mapping

The key features of the Zeta-20 Optical Profiler include:

- Automated extreme edge (XOD) examination of the wafer

- For calibration and monitoring operations

- Full wafer inspection report with classification of defects

- Possible to 3D optical profile defects

- XOD edge trim step height

- In-built microscope review capability

- Corresponding to 100 percent bump inspection instruments

- Manual or automated 200 and 300 mm systems are available

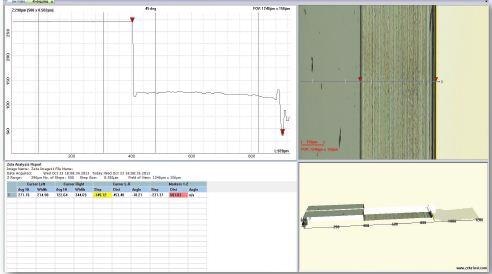

Figure 2. Edge Trim is critical for wafer thinning and dicing. The Zeta-20 Optical Profiler can be used to measure the step height at the extreme edge (XOD) of the wafer.

This information has been sourced, reviewed and adapted from materials provided by KLA Corporation.

For more information on this source, please visit KLA Corporation.