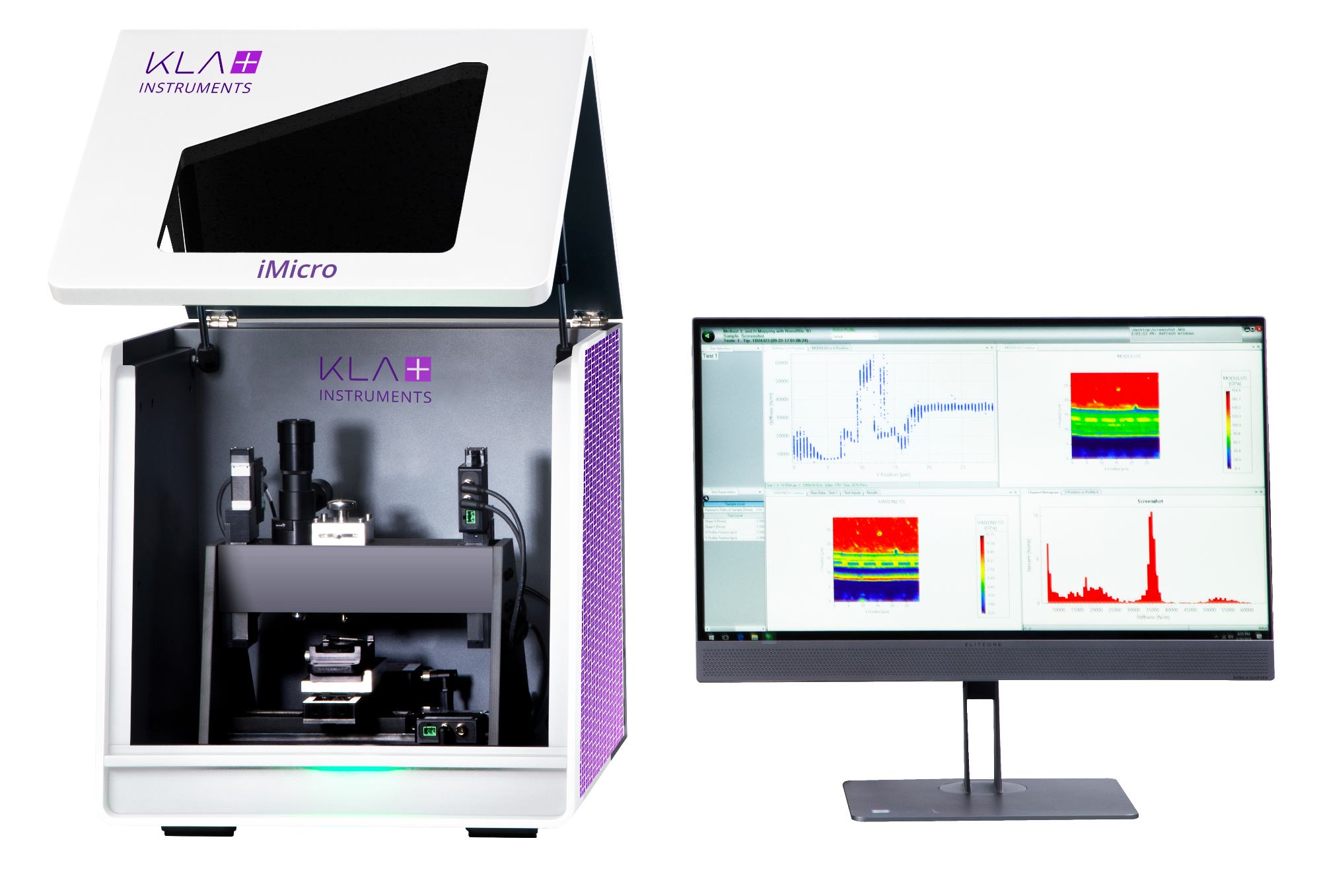

The iMicro nanoindenter is designed to meet material testing requirements such as data accuracy, flexibility, and ease-of-use. It combines the user-friendly software, test reliability, and instrument capabilities of the innovative iNano and enhances the performance further with high load nanoindentation, a vital feature for quality control and R&D labs around the world.

The iMicro offers users high quality data as well as the most data points per dynamic experiment since it has industry-leading 20μs time constants and data acquisition speeds of up to 100 kHz.

The iMicro also provides excellent possible ranges of experiments and applications, with up to 1N of force and 80μm of displacement.

Image Credit: KLA Instruments

Key Features

The main features of the iMicro nanoindenter are as follows:

- Decouple force and displacement - Electromagnetic actuators are linear devices that decouple force and displacement, providing the highest force of 1N, resolution of 6nN and ultra-low noise floor of < 200nN

- Numerous test options - A broad range of tests can be performed using the iMicro, including storage and loss modulus, constant strain rate, frequency specific experiments, and modulus and hardness (Oliver and Pharr)

- Load-frame stiffness - > 3,500,000 N/m

- Numerous actuator options - To meet the most specific requirements for testing any material from hard coatings to ultra-soft gels

- Data confidence - KLA Instruments nanoindenters offer the industry’s broadest range and most reliable data, capable of dynamic excitation frequencies ranging between 0.1Hz and 1kHz

- Smart experiment design - The iMicro includes InView software, a highly powerful and intuitive experiment-scripting platform to promote novel experiments with versatility for setting up and performing virtually any small-scale mechanical test

- Excellent control – The iMicro is the only commercial system to concurrently offer maximum indenter travel of 50μm, digital resolution of 0.02nm, a noise floor of < 0.1nm, and drift rates of < 0.05nm/s, with a time constant of 20μs

- Precise targeting - Sample stage movement of 25mm in the Z axis, 100mm in the X axis, and 21mm in the Y axis with 1nm resolution facilitates a broad range of sample heights and precise sample targeting across a large area

- Automated tip calibration - Unique tip calibration system integrated into the software allows for rapid, accurate and automated tip calibration

- Topography and Tomography Software - Optional NanoBlitz Topography and Tomography Software to perform 3D and 4D mapping of materials

- Scratch - Available scratch option featuring a maximum normal load of 50mN, maximum scratch distance of 2.5mm and a maximum scratch speed of 500µm/s

Customer Testimonials

The state-of-the-art performance of KLA products really helps my research on mechanical properties of novel intermetallic compounds at small length-scales. Moreover, I really appreciate their fast service to resolve any issues. KLA is the best company to work with for anyone who wants to perform nanoindentation.

Seok-Woo Lee, Pratt & Whitney Assistant Professor, Ph.D., Stanford University