Image Credit: Evannovostro/Shutterstock.com

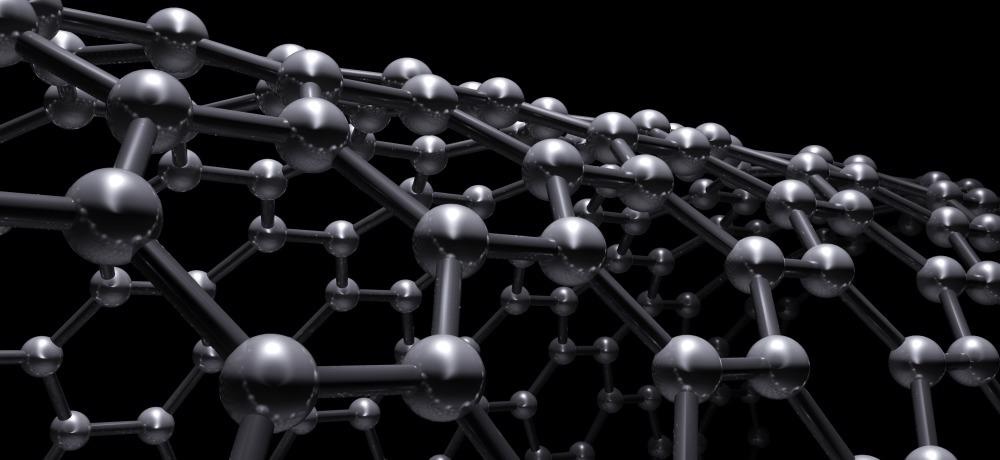

New research has shed light on how the preparation of carbon nanotubes can impact their surface roughness, and, therefore, their properties and suitability for biomedical applications. Here, we discuss this research and its relevance.

The Discovery of Carbon Nanotubes

In 1991, Japanese Physicist Sumio Iijima discovered carbon nanotubes while studying the molecular structure of fullerenes - an allotrope of carbon. In his paper, published in Nature, Iijima described the nanotubes as “helical microtubules of graphitic carbon”. In the years that have followed, the nanometer-sized structures have become a keen focus of scientific researchers as scientists attempt to discover more about their unique properties to develop their use in various applications.

Over three decades, carbon nanotubes have been used in important applications, such as microelectronic circuitry and microscopy, as well as in tools designed to model biological systems and test quantum mechanics.

The potential uses of carbon nanotubes are vast given their advantageous properties, such as having high levels of conductivity, a high melting point, and strong covalent bonds between their atoms. They can be single-walled, with diameters as little as 1 nanometer (nm), or multi-walled, measuring more than 100 nm in diameter. For this reason, scientists have explored how these structures can be taken advantage of. One field in which the use of carbon nanotubes has shown much promise is biomedical science.

The Use of Carbon Nanotubes in Medical Applications

Recent research has shown the huge potential for carbon nanotubes in biomedical applications. Evidence shows that carbon nanotubes are incredibly useful in developing biomaterials is mounting.

The field of reconstructive medicine is dedicated to improving current methodologies of producing functional biological tissues, as well as developing techniques for repairing and replacing tissue and organs damaged by wounds or disease. Carbon nanotubes offer structural and mechanical properties that are advantageous to these applications, while they are highly useful as composites in tissue engineering.

Research has demonstrated that they can be successfully used as drug delivery and gene therapy carriers. They have also proved their use as imaging agents.

Numerous studies have shown that functionalized carbon nanotubes can effectively deliver therapeutics across the blood-brain barrier and that they are also suitable for tumor-targeted therapeutics. Research in this field continues to explore further uses of carbon nanotubes.

To further develop carbon nanotubes in biomedical applications, special importance must be given to deepening our understanding of the influence of nanotube surface roughness on its properties and how to manipulate it.

A recent study conducted by researchers at Arak University and Tarbiat Modares University, both in Iran, used electrostatic force microscopy (EFM) to investigate how different factors in the process of grinding carbon nanotubes influenced the surface roughness. The team based its methodology on Sobol sensitivity analysis to investigate the three factors of velocity, advancement, and cutting depth.

The results showed that velocity and advancement had minimal impact on surface roughness. The speed at which the carbon nanotubes were cut had close to no relationship with surface roughness.

Cutting depth, on the other hand, was found to be the most important factor influencing the surface roughness of carbon nanotubes. The data showed that cutting depth represented a determining factor with 92% surface roughness. The relationship between cutting depth and carbon nanotube surface roughness was inverse, and, therefore, in deepening the cut, the surface roughness was decreased.

The researchers suggest that cutting depth should be considered and used to control the process of cutting carbon nanotubes. It should also be leveraged to inform the arrangement and design of the process.

Conclusions and Future Research

Modern reconstructive medicine is striving to develop innovative techniques for producing functional biological tissues and establishing advanced methodologies for repairing and replacing tissue damaged or lost to wounds or disease.

Carbon nanotubes have emerged as a promising option for developing these advanced techniques due to their unique structural and mechanical properties. Recent research has supported their suitability as use as composites in tissue engineering.

To take full advantage of carbon nanotubes and leverage them in the biomedical space, scientists need to gain a deeper understanding of how the process of preparing and manipulating carbon nanotubes impacts their surface roughness. Surface roughness is vitally important to the properties of carbon nanotubes and dictates how successful they are in biomedical applications.

In a recent study by a team of Iranian researchers, evidence was collected which determined the cutting depth used in the process of grinding carbon nanotubes was the determining factor with 92% surface roughness of the carbon nanotubes.

The study will serve to guide scientists in how they produce and work with carbon nanotubes to ensure that they achieve the right properties required for the biomedical application. The research also helps to develop our understanding of carbon nanotubes, which is vital to furthering their use in all science fields.

References and Further Reading

Jafari, S., 2018. Engineering Applications of Carbon Nanotubes. Carbon Nanotube-Reinforced Polymers, pp.25-40. https://www.sciencedirect.com/science/article/pii/B9780323482219000029

Iijima, S., 1991. Helical microtubules of graphitic carbon. Nature, 354(6348), pp.56-58. https://www.nature.com/articles/354056a0

Taheri, Moein & Bathaee, Hasan. (2021). Investigation of Surface Roughness of Nanoparticles by Applying EFM based on Nanofluids in the Grinding Process of Multi-Walled Nanotubes. https://www.researchgate.net/publication/349928687

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.