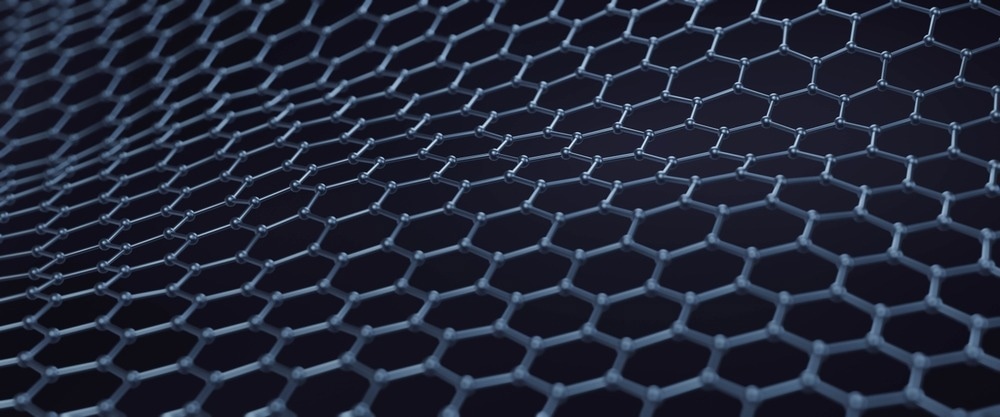

The unique properties of two-dimensional (2D) materials, which are only a few atoms to a single atom thick, differ from those of their three-dimensional (3D) counterparts. 2D materials have had a significant impact in various fields ranging from electronics to medicine. Here, we explore the use of 2D materials and exfoliation techniques to impart unique properties suitable for specific applications.

Image Credit: ART-ur/Shutterstock.com

2D Materials in Commercial and Research Applications

2D materials have unique physicochemical properties and potential applications in various fields, including semiconductor technology, battery electrodes, optoelectronics, energy storage, and superconductivity. These materials are known for their exceptional semiconducting qualities, ultrathin geometry, and outstanding electromechanical response, among other distinctive physical features.

Owing to their large surface area, numerous active sites and edges, enhanced conductivity, resistance to light-induced corrosion, and chemical stability, 2D materials are effective for various applications such as catalysis, sensors, conductive inks, and energy storage.

They are also useful for measuring catalytic reactions such as the oxygen evolution reaction (OER), hydrogen evolution reaction (HER), and oxygen reduction reaction (ORR). In the coating and painting fields, 2D materials are gaining attention as wettable inks or paints that can be printed or coated on various substrates for advanced applications. In addition, they have the potential to improve the durability of construction materials and increase the strength of the cement, thereby providing stronger structures.

2D materials have also been used to develop specialty building materials with properties such as acoustic and thermal insulation and fire resistance, owing to their high strength, large surface area, and ultrathin sheet structures.

Exfoliating 2D Materials: Techniques and Reasons Behind Their Use

The ability to separate nanosheets of 2D materials from their bulk crystals is facilitated by their strong in-plane and weak out-of-plane bonds. As a result, it is possible to obtain large 2D nanosheets measuring hundreds of micrometers in width and only a few atomic layers in thickness.

2D materials, including graphene, TMDs, and other related materials, have attracted considerable attention because of their unique structural, optoelectronic, and mechanical properties that have been recently discovered.

These materials have promising applications in optoelectronic devices and as functional nanostructured membranes. However, their potential can only be fully realized after they have been successfully exfoliated from their layered assemblies into high-quality monolayer samples.

Mechanical exfoliation, originally used to isolate graphene, is one of the most successful techniques for achieving this goal. Additionally, the development of a critical technology for transferring 2D materials from their host substrate to another surface in a monolayer or few-layer form is crucial for the successful application of 2D materials and the construction of van der Waals heterostructures, where 2D sheets are arranged in a specific layered order.

Theoretical models for mechanical design can help in the successful exfoliation or transfer of atomically thin membranes. Specifically, a peeling force must be applied to the single- or few-atom-thick sheets through their attachment to the stamp material, such as scotch tape, to cleave the sheet from the substrate. The five most frequently employed exfoliation methods include ultrasonication, micromechanical cleavage, ball milling, shear exfoliation, and electrochemical exfoliation.

Recent Studies

An article published in Ceramics International reported the creation of ultrathin MXenes with a high exfoliation degree through a combination of hydrofluoric acid (HF) etching, dimethyl sulfoxide (DMSO)--assisted layer expansion, and ultrasonic peeling.

The catalytic performance of the ultrathin MXene was evaluated for the thermal decomposition of three types of energetic materials: dihydroxylammonium 5, 5'-bistetrazole-1, 1'-diolate (TKX-50), cyclotetramethylene tetranitroamine (HMX), and ammonium perchlorate (AP).

The results revealed that incorporating 4 wt% of ultrathin MXene led to a reduction in the decomposition temperature of TKX-50 by 33.6 °C and 45.5 °C for AP, suggesting superior catalytic performance compared to non-exfoliated MXene. Nevertheless, this had a minimal impact on HMX.

Various analyses, including surface chemical analysis, thermal decomposition, electrochemical characterization of gaseous products, and material studio simulations, confirmed that the highly exfoliated ultrathin MXene exhibited better stability and electrical conductivity, which facilitated the acceleration of the proton transfer process and rapid gas release from energetic materials.

Additionally, ignition tests demonstrated that highly exfoliated ultrathin MXenes can effectively participate in the ignition process of energetic materials. After high-temperature and oxidation treatment, the characterization and thermal analysis of MXene products indicated that the catalytic activity was weakened due to high-temperature crystal collapse and surface oxidation to titanium oxide metamorphism. This study provides new insights into applying MXene catalysts as energetic materials.

Another study published in the Chemical Engineering Journal introduced a gas-driven shear exfoliation method for producing few-layered molybdenum sulfide (MoS2) flakes with a high aspect ratio at a low cost and high production rate.

The method was found to be facile and scalable, producing flakes of an average thickness of 3 nm and a lateral dimension of more than 10%. In a lab-scale setup, the production rate reached 1.23 g/h, and the exfoliation energy consumption was 0.175 kW⋅h/g.

At the industrial level, the production rate exceeded 3 kg/h, which marked a significant advancement towards low-cost mass production of few-layer MoS2. The as-exfoliated few-layer MoS2 was employed as an active material for supercapacitors and exhibited good electrochemical performance with a specific capacity of 101.8 mAh/g. After 5000 cycles, capacitance retention was sustained at a high level of 92.9%.

Industry Key Players

Top key players developing exfoliation solutions for 2D materials include Advanced Material Development, Applied Nanolayers, Evercloak, FlexeGRAPH, and DENSsolutions.

Conclusion

Overall, 2D materials and their exfoliation techniques have unlocked a world of transformative potentials across multiple industries. These ultrathin materials, unlike their 3D counterparts, exhibit exceptional qualities, such as reshaping electronics, energy, catalysis, and even construction.

Their unique physicochemical properties, including extraordinary conductivity, large surface area, and robust stability, make 2D materials pivotal for a wide range of applications, from catalysis and sensors to energy storage.

Exfoliation techniques such as mechanical exfoliation have enabled the isolation of monolayer samples, allowing the construction of intricate van der Waals heterostructures—various methods, ranging from ultrasonication to shear exfoliation, offer pathways to obtain high-quality monolayers.

The journey through these advancements highlights the transformative power of 2D materials and exfoliation techniques, promising continued innovation across industries and opening doors to novel applications that redefine possibilities in material science and technology.

References and Further Reading

Kumbhakar, P., et al. (2023). Prospective applications of two-dimensional materials beyond laboratory frontiers: A review. iScience, 26(5), p.106671. doi.org/10.1016/j.isci.2023.106671

Gao, E., et al. (2018). Mechanical exfoliation of two-dimensional materials. Journal of the Mechanics and Physics of Solids, 115, pp.248-262. doi.org/10.1016/j.jmps.2018.03.014

Liu, D., et al. (2024). Reaction mechanism of exfoliation degree and high temperature surface oxidation metamorphism of 2D Ti3C2Tx on thermal decomposition of various energetic materials. Ceramics International, 50(1), pp.2221-2232. doi.org/10.1016/j.ceramint.2023.10.337

Zhang, Z., et al. (2024). Exceptionally high-rate production of few-layer MoS2 by a scalable and cost-effective gas-driven shear exfoliation method and its application for supercapacitors. Chemical Engineering Journal, p.479. doi.org/10.1016/j.cej.2023.147551

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.