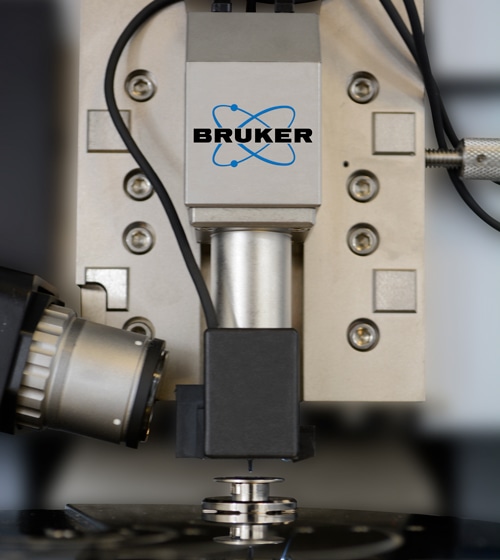

The Hysitron TriboScope® from Bruker delivers quantitative, rigid-probe nanoindentation and nanotribological characterization features to the field of atomic force microscopy. The Hysitron TriboScope interfaces with Bruker’s Dimension Icon®, MultiMode® 8 and Dimension Edge™ AFMs to expand the characterization features of these microscopes. By employing a rigid test probe, the TriboScope removes the fundamental limitations, complexity and variability related to cantilever-based measurements to provide quantitative and repeatable mechanical and tribological characterization over nanometer-to-micrometer length scales

Quantitative, Reliable and Repeatable

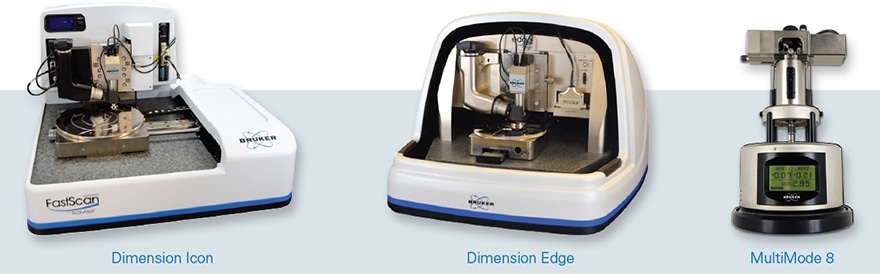

Expanding the Capabilities of our Industry-Leading AFMs

The TriboScope quickly interfaces to Bruker’s Dimension Icon, MultiMode 8 and Dimension Edge systems.

The TriboScope Advances Research with Innovative Testing Modes

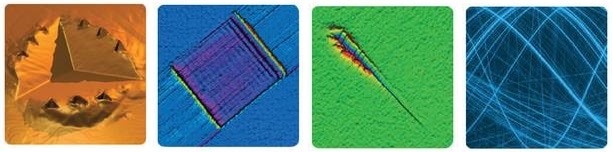

- Quasi-Static Nanoindentation - Perform quantitative measurement of elastic modulus, hardness, stress relaxation, creep and fracture toughness of localized microstructures, small surface features, interfaces and thin films.

- Scanning Wear - Raster scan the test probe over the sample surface at a user-definable force set point for quantitative wear resistance characterization at the nanoscale.

- In-Situ SPM Imaging - Employ the same test probe for testing and topographic imaging for nanometer precision test placement accuracy and the ability to characterize post-test material deformation behavior.

- nanoDMA III - Dynamic Nanoindentation - Continuously measure elastic-plastic and viscoelastic properties as a function of frequency, indentation depth and time with Bruker’s nanoDMA® III option.

- NanoScratch - Perform friction coefficient, quantitative scratch/mar resistance and thin film adhesion measurements with Bruker’s exclusive 2D lateral force transducer technology.

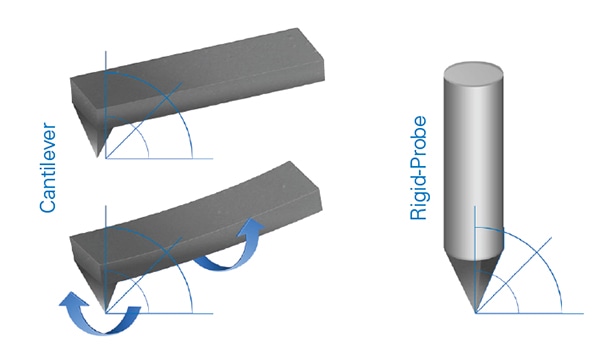

The Rigid-Probe Advantage

Most AFMs utilize a compliant cantilever to conduct mechanical or tribological testing, posing significant challenges in separating a cantilever’s flexural and rotational stiffness from the material’s response to applied stress. The TriboScope utilizes a rigid test probe assembly, allowing direct control and measurement of applied force and displacement during the test.

Electrostatic Actuation

The TriboScope utilizes proprietary electrostatic force actuation and capacitive displacement sensing transducer technology to deliver industry-leading low thermal drift and noise floors for characterizing properties to the bottom of the nanoscale.

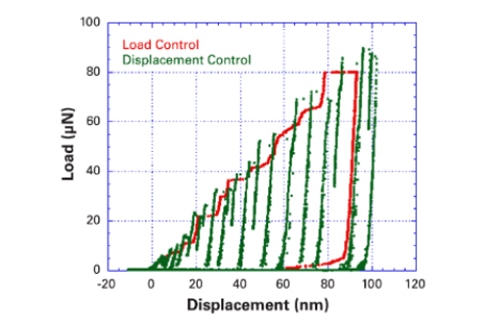

Force and Displacement Feedback Control

The TriboScope functions under displacement control or closed-loop force control. Utilizing a 78 kHz feedback loop rate, the TriboScope can respond to rapid material deformation transient events and dependably reproduce the test function specified by the operator.

TriboScope Features

- Industry-leading transducer technologies offer measurement of elastic modulus, creep, fracture toughness, stress relaxation, hardness and viscoelastic properties over nanometer-to-micrometer length scales

- Quantitative, rigid-probe characterization removes the doubts and complexities intrinsically caused by cantilever-based nanoindentation and nanotribological testing techniques

- An intuitive mechanical interface simplifies integration with standard commercially available AFMs, including Bruker’s Dimension Edge, Dimension Icon and MultiMode 8 systems

- Enables quantitative nanomechanical and nanotribological characterization of the widest range of materials, from soft polymers to ultra-thin diamond thin films

- Proprietary capacitive transducer and Performech® control technologies offer better control over the nanoindentation process and deliver industry-leading force and displacement noise floors

- In-situ SPM imaging provides nanometer-precision test placement accuracy and observation of post-test material deformation behavior

Specifications

| . |

. |

| Standard Configuration |

| Testing Modes |

Quasi-Static Nanoindentation, In-Situ SPM Imaging, Scanning Wear |

| Normal Force |

Maximum Force: 10 mN

Noise Floor: <30 nN

Resolution: 1 nN |

| Normal Displacement |

Maximum Displacement: 5 µm

Noise Floor: <0.2 nm

Resolution: 0.006 nm

Drift Rate: <0.05 nm/sec |

| Optional Configurations |

| nanoDMA Ill |

| Testing Modes |

Dynamic Nanoindentation, Quasi-Static Nanoindentation, In-Situ SPM Imaging, ScanningWear |

| Dynamic Specifications |

Frequency Range: 0.1 Hz - 300 Hz

Maximum Dynamic Force Amplitude: 5 mN

Maximum Dynamic Displacement Amplitude: 2.5 µm |

| NanoScratch |

| Testing Modes |

NanoScratch, Quasi-Static Nanoindentation, In-Situ SPM Imaging, ScanningWear

Maximum Displacement: 15 µm

Displacement Noise Floor: <2 nm |

| Lateral Specifications |

Maximum Force: 2 mN

Force Noise Floor: <3.5 µm |