Compared to pneumatic or hydraulic liquid processors, the HandGenizer is an eco- and budget-friendly mini homogenizer. It is a manual high pressure homogenizer that works by shifting the pump handle up and down.

It needs no PLC control system or electricity and is perfect for basic experimental tasks, particularly when handling small quantities of liquid samples.

Genizer Mini Hand Homogenizer, Max. 30,000 psi. Image Credit: Genizer LLC

The HandGenizer’s mini pump has been designed specifically to provide the preferred pressure to the product stream. When the pump handle is lifted, a small quantity of the sample will be pulled into the mini-pump body.

By shifting the pump handle fully down to make a high-pressure profile (maximum 30,000 psi) to the sample stream, this portion of the sample will enter the check valve and the Genizer Y-Type diamond interaction chamber. Finally, it exits the outlet to be collected.

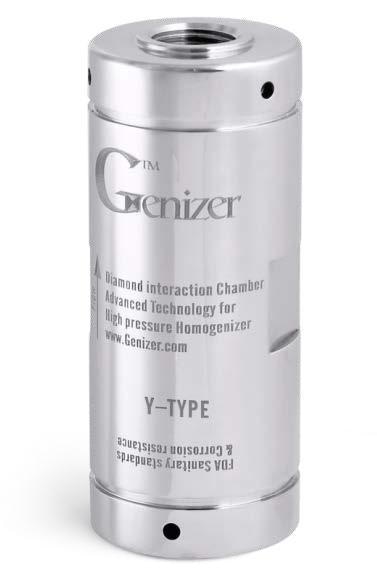

The flow stream has been divided into two channels inside the Genizer Y-Type diamond interaction chamber and further redirected over the same plane at right angles and pushed into a single flow stream.

The high pressure (maximum 30,000 psi) generates a high speed at the crossover of the two flows, leading to turbulence, high shear and cavitation over the single outbound flow stream inside the Genizer Y-Type diamond interaction chamber.

Genizer Y-Type diamond interaction chamber for HandGenizer Homogenizer. Image Credit: Genizer LLC

HandGenizer combines with Genizer extruder to achieve liposome extrusions. Image Credit: Genizer LLC

Features of the HandGenizer

- Diamond interaction chamber (Electro-polish and passivation available for pharmaceutical applications)

- Spares and tools

- Application: Nano emulsions and liposomes

- Pressure ranges up to 30,000 psi

- Power: Manual operations

- Minimum sample volume: 2 ml

- Capacity: 10 to 30 ml/min@ 30, 000 psi