The NanoGenizer-30K from Genizer is an electric benchtop, laboratory-scale, high-pressure homogenizer, which has been developed specifically for bacterial and cell lysis (such as yeasts and E. coli).

It aids laboratory research and development and small-scale production at ultra-high pressure (maximum pressure up to 45,000 psi/3,000 bar), and there is no requirement for hydraulic oil or compressed air. It is available in both the 3D-printing and stainless versions.

NanoGenizer High-Pressure Homogenizer, Plug & Play, for cell disruptions. Image Credit: Genizer LLC

Main Features of the NanoGenizer

- Diamond interaction chamber (Electro-polish and passivation available for pharmaceutical applications)

- Flow rate (water value): approximately 100 ml/minute @ 30,000 psi

- Pressure: 25,000 psi, 30,000 psi and 45,000 psi

- Weight: approximately 35 kg

- Minimum sample volume: 5 ml

- Precision sampling as accurate as 0.1ml resolution

- Application: Nano emulsions, liposomes, fat emulsions, nano dispersion, cell disruption, deagglomeration, graphene, and carbon nanotube

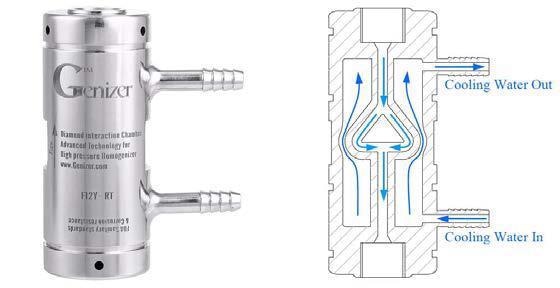

The diamond interaction chamber is the key component of the NanoGenizer high-pressure homogenizer. It makes use of microfluidic technology, and the inside has been provided with nano-size micro-channels. Here, the user's formulation is exposed to forces of strong impact and high shear, thereby leading to nano cell disruption and nanoparticle dispersion.

The micro-jet of the sample can reach speeds of 1,000 m/second, which is quicker than the speed of sound (340 m/second), after being accelerated and pressurized through the intensifier. Once the high-speed bullet-type micro-jet passes via the micro-channels of the diamond interaction chamber, it goes through complicated physical effects, for example, high-energy impact, high-frequency shearing, cavitation and pressure drop, etc. Then, the material is nano-sized and homogenized.

Genizer diamond interaction chamber with cooling, F12Y-RT. Image Credit: Genizer LLC

Nano Emulsion, Liposome, NanoCosmetic, Nanomaterial. Image Credit: Genizer LLC

When compared with the traditional homogenizing valve, there are no moving parts within the Genizer diamond interaction chamber. This guarantees identical results among various batches.

It can also be used extensively in the biochemical, pharmaceutical, cosmetics, food and dairy industries, among others. Also, it can aid experimentation from particle size reduction to cell disruption, nano dispersions, nano emulsions, liposomes and more.

Enhanced Features

- Control System: PLC touch screen, auto stop on passes, digital pressure value and volume

- Comes with a ceramic plunger

- Warranty period of one year against any manufacturing defects

- Tools and spares

- Cooling System: The heat exchanger and the diamond interaction chamber have been developed with cooling ports

- CE compliant and RoHs compliant

- Glass and 316 L stainless steel feed reservoir available as options