The Diamond Interaction Chamber (DIXC) is a core component of the NanoGenizer high-pressure homogenizer. It uses microfluidic technology, and the inside is designed with fixed-geometry microchannels, where the formulation is subjected to forces of high shear and substantial impact, resulting in nanoparticle dispersion and nano-cell disruption.

After being pressurized and accelerated by the intensifier, the sample’s micro-jet can reach speeds of 1,000 m/second, faster than the speed of sound (340 m/second).

When the high-speed bullet-type micro-jet passes through the diamond interaction chamber’s micro-channels, it undergoes complex physical effects, such as high-frequency shearing, high-energy impact, cavitation and pressure drop, and more. After that, the material is homogenized and nano-sized.

In comparison to the more conventional homogenizing valve, the Genizer Diamond Interaction Chamber has no moving parts within the chamber, which guarantees similar outcomes for different batches. It can also be broadly employed in the biochemical, pharmaceutical, cosmetics, dairy, and food industries. It has also been found to aid in experimentation from particle size reduction to cell disruption, nanodispersions, nanoemulsions, liposomes, etc.

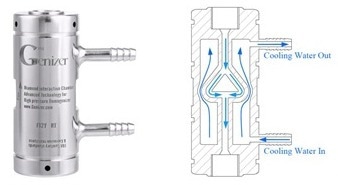

Cooling Options

The conventional approach cools the chamber by completely immersing it in the cooling bath; however, the thick steel cover of the chamber makes this an unviable solution.

The patent fabrication of Genizer has the cooling option within the chamber, enabling a much more efficient exchange of heat.

Diamond Interaction Chamber with Cooling Option. Image Credit: Genizer LLC

Types

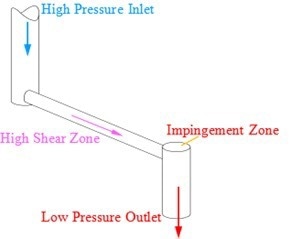

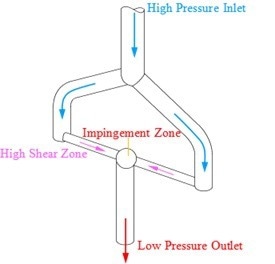

There are two kinds of DIXC: the “Y” and the “Z” types. These two kinds can also be categorized into various sizes ranging from experimental to production.

Z-Type Diamond Interaction Chamber. Image Credit: Genizer LLC

Y-Type Diamond Interaction Chamber. Image Credit: Genizer LLC