First Graphene Limited (“First Graphene”) is pleased to provide an update on its role in the cross-sector A$3.72 million HyPStore project.

Image Credit: First Graphene Ltd

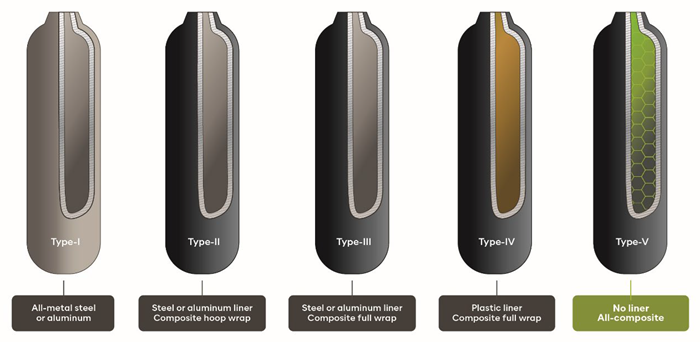

The aim of the project is to develop and commercialize novel light-weight impermeable cryogenic tanks, designed for the safe storage and transportation of liquid hydrogen (see Figure 1).

There are nine entities from Australia and the UK involved in the project, which has already commenced the manufacture of a prototype Type V tank and developed the necessary means to test key aspects at cryogenic temperatures.

First Graphene has started testing graphene materials provided by Australian Sunlight Group (“ASL”) to formulate a graphene-enhanced resin system, which will be tested against the Company’s PureGRAPH® material.

The addition of graphene nanoplatelets in resin will assist creating an impermeable tank, by forming a protective barrier within the tank structure. This process has previously demonstrated a reduction in hydrogen permeability by up to 48 times.

First Graphene’s dedicated testing equipment (see Figure 2) has been constructed within the Company’s research and development laboratory in Manchester in the United Kingdom.

Figure 2. The Tinius Olsen Universal Tester is designed to test graphene-enhanced resin systems for use in storag tanks. Image Credit: First Graphene Ltd

The Tinius Olsen Universal Tester measures the performance of raw materials or products using a series of tests, including evaluating tensile, compressive, and flexural strength.

This equipment will be used to test First Graphene’s materials for use in the HyPStore project during Q1 of the new financial year, as well as support the Company’s client base across various sectors in future.

The Company is also working with consortia members to leverage its expertise of graphene nanoplatelets to manufacture materials that optimize fire retardancy and inherent strength of the storage tanks.

The A$3.72 million project is supported by A$1.73 million in funding delivered through Innovate UK’s UK – Australia Renewable Hydrogen Innovation Partnership Programme.

Upscaling 3D Printing Opportunities

First Graphene has also embarked on a 10-month project in partnership with Imperial College London (ICL) and University College London (UCL) to assist upscaling chemically modified graphene for use in 3D printing of metals.

The EFFICIENT Project has received a grant of A$1.2 million from Innovate UK to investigate the use of graphene to improve laser printing processes, including the potential to reduce energy requirements and associated costs.

Chemically modified graphene developed in the project is specifically being used to enhance laser light absorption and heating efficiency of copper-based material used in 3D printing.

Incorporating graphene into copper metal can enable the material to better absorb energy from the laser, allowing it to melt at a faster rate and lower temperature.

First Graphene will assist with scaling the chemically modified graphene technology while also investigating how PureGRAPH® can perform as an alternative given readily accessible volumes of the Company’s product.

3D printing of metal components is often used in high-end applications, including aerospace and motor sports, where manufacturers are required to develop complex, lightweight and efficient components, faster and with less energy.

First Graphene’s involvement in this project could help fast-track the technology to market, meeting growing demand for more sustainable products in this industry.

First Graphene Managing Director and CEO Michael Bell said:

“It’s fantastic to see new opportunities presented through multiple research and development avenues, leveraging our knowledge and expertise of graphene alongside the university sector to advance commercialization.

The HyPStore project has progressed testing of graphene resin for use in hydrogen tanks, which will assist with safe storage and transportation of this emerging clean energy.

Our involvement in this globally significant project ensures the broader consortia can benefit from key IP our team has developed on the use of graphene in composites.

In turn, this project has also provided our team with a greater understanding of graphene’s performance as an additive in resins, which has already led to further commercial work for First Graphene in the Carbon Fiber and Kevlar space.

The opportunity to help upscale a new graphene technology to deliver efficiency benefits to the rapidly growing aerospace industry and high-end motorsport sector will also open new doors for First Graphene.

Both projects further reinforce the versatility of graphene as a high-performing additive and commercially available material for high-demand, future-facing industries.”