The measurement and mapping of properties like the elastic modulus and hardness is the most important application of nanoindentation. It so follows then that the most vital properties of a nanoindenter are its ability to detect minute changes in these properties, as well as the spatial resolution that these properties can be measured at.

Here are two major benefits related to the MEMS-based core technology featured in both the FT-IO4 Femto-Indenter and the FT-NMT04 in-situ SEM Nanoindenter. These advantages are ultra-low noise floors and high repeatability, in both force and displacement sensing.

The FemtoTools nanoindenters, as demonstrated by the data of hardness and modulus measurements on fused silica, display repeatability which is unprecedented. This precision, as a direct consequence, permits the detection of ultra-small variations in modulus and hardness values.

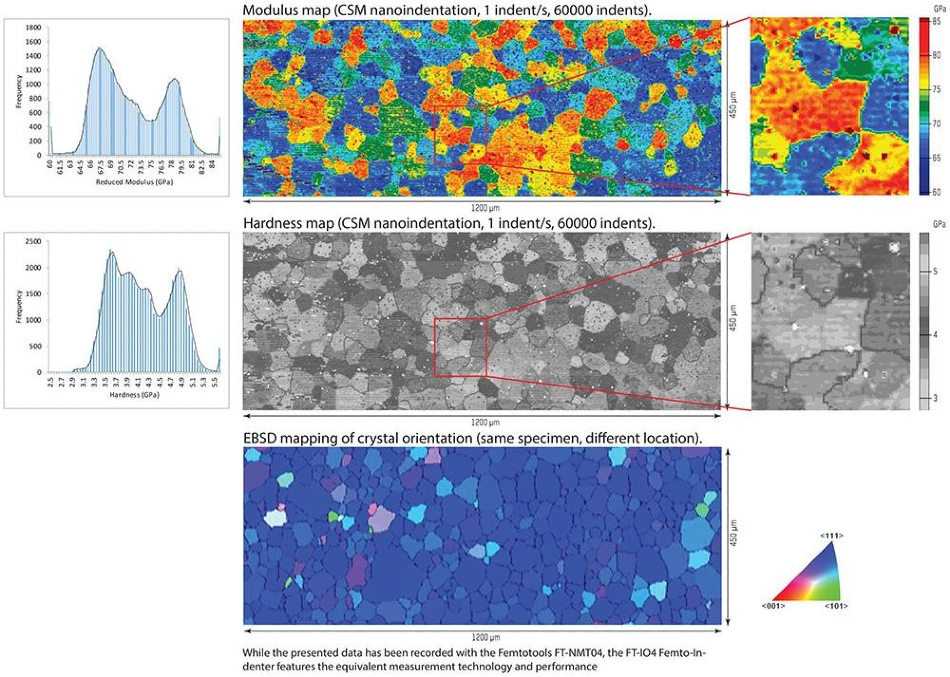

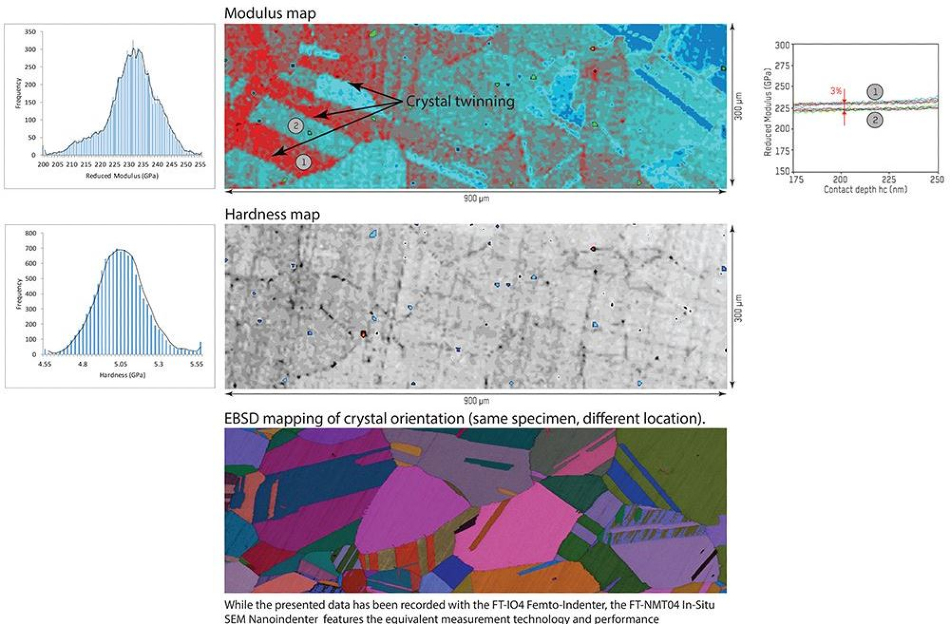

In order to display this capability, the accompanying results from CSM nanoindentation measurements on a single-phase alloy (namely austenitic Nickel-based alloy 690 and NiTi alloy) are displayed here.

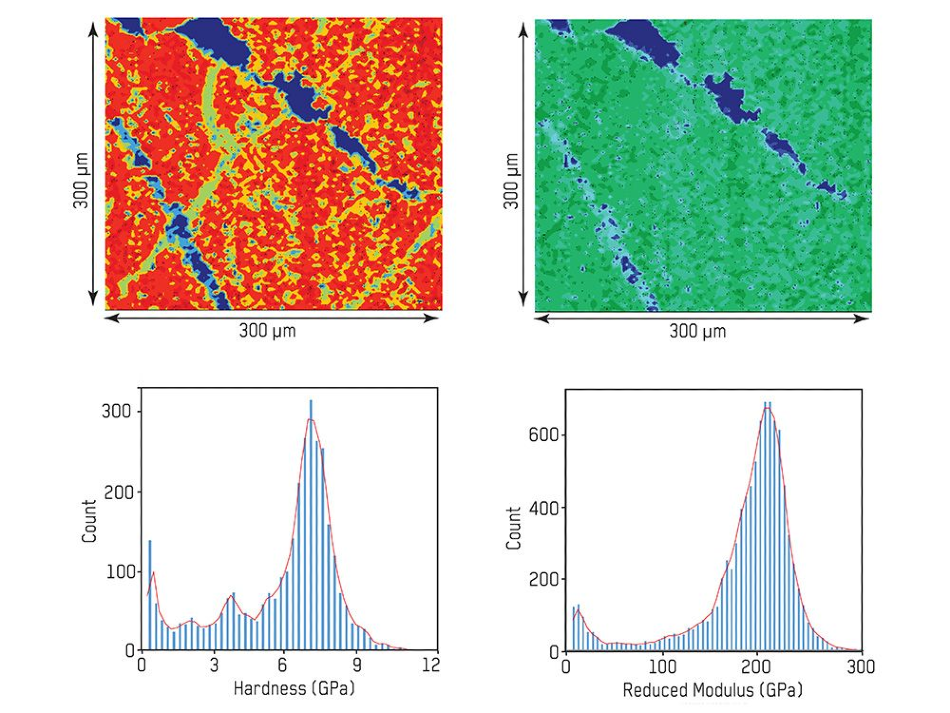

It is not only the hardness and modulus of fine particles from soft dirt residues (H=500 MPa) to hard carbide precipitates at grain boundaries (H=15 GPa) which the FemtoTools nanoindenters can facilitate the measurement of. FemtoTools nanoindenters can measure very small variations in modulus (3%), which relate to changes of crystal orientation. This measurement can then be compared qualitatively to the EBSD map (taken from the same sample in a different location).

To allow the study of the different mechanical properties in a variety of specimens, whether at interfaces or over heterogeneous microstructures, the FemtoTools nanoindenters have sample stages that combine a wide range (from 12x12 to 130x130 mm) with a 1 nm position noise floor. This feature allows the specific and repeatable targeting of certain locations.

In addition, the automated mapping of mechanical properties is facilitated, over large areas, with high-resolution. FemtoTools, in its Software Suite, offers tools to facilitate extensive visualization and data analysis along with statistics, profiles, and color maps of all derived and measured properties.

This information has been sourced, reviewed and adapted from materials provided by FemtoTools AG.

For more information on this source, please visit FemtoTools AG.