Autosorb instruments are high-vacuum physisorption and chemisorption analyzers that can measure BET surface area, active area, and pore size distributions. Independent analysis stations, proprietary TruZone active coolant control, and accessible Kaomi software allow users to satisfy current measurement requirements while adapting to future ones through factory and field upgradeable options. Absolute Autosorb is the clear option for the most significant gas sorption measurements.

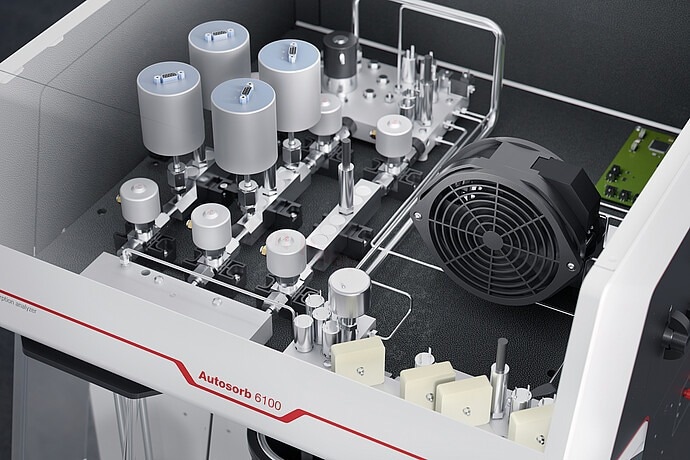

- Autosorb 6100

- Precise high vacuum physisorption assessments of surface area and micropores

- Advanced measurement techniques made available with DoseWizard point selection and PowderProtect

- Independent analysis stations can measure up to three samples, three gases, and three temperatures at the same time.

- Autosorb 6200

- Accurate physisorption and chemisorption analyses for advanced catalyst characterization

- Selection of chemical compatibility to suit the measurement requirement

- Upgradeable to include TCD, integrated mass spectrometer, and vapor option

- Autosorb 6300

- Completely characterize the catalyst using the accompanying TCD, pulse titration loop, and built-in vapor source.

- Enhanced chemical resistance enables a wider variety of analytical gases and applications.

- Full chemisorption and physisorption capabilities in a single instrument package

Key Features

A Gas Sorption Analyzer That is Accurate

Image Credit: Anton Paar GmbH

- Obtain extremely accurate physisorption readings from relative pressures less than 10–7 for nitrogen.

- Utilize accurate manifold temperature control, ranging from 35 to 50 °C

- Even during extended analyses, rely on TruZone active coolant level management for precise results

- Superior high vacuum performance can be attained using precision-machined manifolds and premium pneumatic valves, which are 38% better than previous-generation instruments

Independent Stations Ensure Users are Agile

Image Credit: Anton Paar GmbH

- Users can concurrently analyze up to three samples at different temperatures using three distinct analysis gases by employing separate analysis stations and patented temperature control accessories.

- Use six integrated degassing stations to increase throughput

- Quickly switch to the 1100 °C furnace for sophisticated temperature programmed studies, pulse titrations, or chemisorption isotherms

Intuitive Software Makes Every Analysis Accessible

Image Credit: Anton Paar GmbH

- Enjoy an upgraded and streamlined Kaomi software, making the entire measurement process easier than ever before

- DoseWizard's new standard and advanced modes allow users to tailor measurement definitions to specific requirements.

- PowderProtect minimizes downtime by preventing inadvertent powder loss in the instrument.

Customization Options Keep Users Adaptable

Image Credit: Anton Paar GmbH

- With three instruments and flexible modifications, the Autosorb responds to the specific analytical needs of porous materials and catalysts.

- The instrument's physisorption and chemisorption capabilities can be updated to accommodate new materials and applications as the study evolves.

- Enhanced chemical resistance, an integrated vapor source, a thermal conductivity detector, or even a completely integrated mass spectrometer can help users go beyond routine tests.

Compliance and Quality are Assured

Image Credit: Anton Paar GmbH

- Comply with over 20 ASTM, DIN, and ISO standards for catalyst characterization and porous solid assessment.

- Get peace of mind with a three-year warranty so users can avoid unforeseen costs.

Technical Specifications

Measurement Specifications. Source: Anton Paar GmbH

| |

Autosorb 6100 |

Autosorb 6200 |

Autosorb 6300 |

| Measurement principle |

- Vacuum Volumetric Physisorption

|

- Vacuum Volumetric Physisorption

- Vacuum Volumetric Chemisorption

- Dynamic Flow Chemisorption (Optional)

|

- Vacuum Volumetric Physisorption

- Vacuum Volumetric Chemisorption

- Dynamic Flow Chemisorption

|

| Analysis gas compatibility |

|

|

|

| N2, Ar, Kr, CO2, H2, and other non-corrosive gases |

Included |

Included |

Included |

| CH4, C2H6, C3H8, other alkanes, C6H6, C8H10 |

Included |

Dependent on instrument configuration |

Included |

| NH3, C5H5N, C3H6O, and other reactive gases |

N/A |

Dependent on instrument configuration |

Included |

Physisorption

analysis

stations |

Number: 1, 2, or 3

Independence: Up to three gases at three analysis temperatures can be used concurrently; one analysis gas and temperature per station |

| Chemisorption analysis stations |

N/A |

1 |

| Independent p0 station |

Yes (dedicated cell and transducer) |

| Pressure |

- Range: 2x10-5 to 1100 Torr (2.6x10-8 to 0.997 p/p0 for N2 77K)

- Resolution (MP): 2x10-5 Torr (2.6x10-8 p/p0 for N2 77K)

- Resolution (XR): 1x10-6 Torr (1.3x10-9 p/p0 for N2 77K)

|

| BET surface area |

- Absolute detection limit: 0.1 m2 (N2 77K)

- Specific detection limit: 0.01 m2/g (N2 77K)

- Typical reproducibility: 1 % (measured on BAM P115)

- Reproducibility limit: 2 % with 2 m2 in the cell

|

| Pore size |

- Range: 0.35 nm to 500 nm (diameter)

- Typical reproducibility: 0.5 % (measured on BAM P115)

|

| Active area |

N/A |

- Absolute detection limit: 0.03 m2 (H2 on Platinum 313 K)

- Specific detection limit: 0.003 m2/g (H2 on Platinum 313K)

- Typical reproducibility: 2 % (measured on 2% Platinum on Alumina reference sample)

|

| TruZone |

Yes (active coolant level control) |

| PowderProtect |

Yes (prevents sample elutriation) |

| Analysis dewar |

- Duration: 90+ hours with liquid nitrogen

- Refill during analysis: Yes

- Volume: 3 L

|

| Analysis furnace |

N/A |

- Maximum temperature: 1,100 °C

- Maximum Ramp Rate: 50 °C per minute

- Furnace cooling by built-in fan

|

| Sample preparation |

- Integrated degassing stations: 6

- Temperature control: 2 independent heating zones, ambient to 450 °C

- Dedicated cold trap: Yes

- Available methods: flow and vacuum, programmable multi-step degassing profiles, test for completion routines, pressure-controlled heating

|

| Additional capabilities |

|

|

|

| Vapor source |

Optional |

Optional |

Included |

| CryoSync control |

Optional |

Optional |

Optional |

| TCD and loop injector |

N/A |

Optional |

Included |

| Mass spectrometer |

N/A |

Optional |

Optional |

Kaomi software features. Source: Anton Paar GmbH

| |

Autosorb 6100 |

Autosorb 6200 |

Autosorb 6300 |

| Instrument connection |

Control up to 4 instruments from 1 PC |

| DoseWizard |

- 45+ built-in analysis profiles aligned with ASTM, DIN, and ISO

- Standard profiles with easy measurement selection

- Advanced profiles with full control of experimental procedures

- Dose templates for rapid measurement based on previous analyses

|

| Physisorption methods |

- Surface area and pore volume: Alpha-s, BET, DR, Gurvich pore volume, Langmuir, t-plot (STSA)

- Pore size and pore volume distributions: NLDFT, QSDFT, GCMC, Kr(87) thin-film, BJH, DH, DA, HK, SF, MP

- Other: summary reports, overlays, average particle size, average pore size, fractal dimensions (NK, FHH), heat of adsorption

|

| Chemisorption methods |

N/A |

- Static measurements: extrapolation, bracketing, Langmuir, Temkin, Freundlich, heat of adsorption

- Dynamic flow measurements: TPx (TPR,TPO,TPD) peak deconvolution, pulse titration analysis, activation energy

|

| Available languages |

|

|

Chinese, English, French, German, Japanese, Korean, Portuguese, Spanish |

Technical Specifications. Source: Anton Paar GmbH

| |

Autosorb 6100 |

Autosorb 6200 |

Autosorb 6300 |

| Dimensions (W x D x H) |

79.5 cm x 70.1 cm x 107.9 cm (31.3 in x 27.6 in x 42.5 in) dependent on instrument configuration |

| Weight |

136.4 kg (300 lbs) dependent on instrument configuration |

| Operating environment |

- Temperature: 15 °C to 35 °C (59 °F to 95 °F)

- Humidity: 20% RH to 80% RH, non-condensing

|

| Gas distribution manifold elastomers |

FKM |

FKM or EPDM (dependent on instrument configuration) |

PFE |

| Analysis manifold construction |

Vacuum-brazed manifold block in stainless steel |

| Analysis manifold temperature |

- Range: user adjustable 35 °C to 50 °C

- Stability: ±0.05 °C

|

| Analysis manifold valves |

- Type: stainless steel, air-operated bellows valve

- Cycle life: 5,000,000 cycles

- External leak rate: 5x10-12 Pa m3/sec

- Seat leak rate: 5x10-12 Pa m3/sec

|

Pressure transducer (1550 Torr)

-Analysis and degas |

- Number: 3 to 5 (dependent on instrument configuration)

- Accuracy: ±0.1 % of span typical, ±0.15 % of span maximum

- A/D data acquisition: 32 bit

|

Pressure transducer (10 Torr)

– MP or XR |

- Number: 1 to 3 (dependent on instrument configuration)

- Accuracy: ±0.15 % reading up to 10 Torr

- Resolution: 0.002 % full scale

|

Pressure transducer (1 Torr)

– MP only |

- Number: 1 to 3 (dependent on instrument configuration)

- Accuracy: ±0.15 % reading up to 1 Torr

- Resolution: 0.002 % full scale

|

Pressure transducer (0.1 Torr)

– XR only |

- Number: 1 to 3 (dependent on instrument configuration)

- Accuracy: ±0.15 % reading up to 0.1 Torr

- Resolution: 0.001 % full scale

|

Pirani vacuum gauge

– Degas only |

- Number: 1

- Accuracy:

5×10-4 to 1x10-3 Torr: ±10 % of reading

1×10-3 to 100 Torr: ±5 % of reading

- 100 Torr to atmosphere: ±25 % of reading

|

| Vacuum system |

- Turbo molecular drag pump and dry diaphragm pump

- Manufacturer’s specification: 5x10-10 mbar

- Typical pressure at analysis port: 2.67x10-5 mbar

|

| Thermal conductivity detector (TCD) |

N/A |

- Two-filament TCD with rhenium/tungsten filaments (optional)

- Detection Limit: 0.5 uL (air injected into helium)

|

- Two-filament TCD with rhenium/tungsten filaments (standard)

- Detection Limit: 0.5 uL (air injected into helium)

|

| Gas ports |

- 7 ports standard (5 analysis, 1 helium, 1 degas/backfill)

- 7 additional analysis ports optional

|

- 7 ports standard (5 analysis, 1 helium, 1 degas/backfill)

- 7 additional analysis ports optional

- 1 titration gas port optional

|

- 15 ports standard (12 analysis, 1 helium, 1 degas/backfill, 1 titration)

|

| Gas supply |

- Purity: 99.999 %

- Input pressure: 8 psig to 10 psig (0.55 bar to 0.69 bar)

|

| Air |

- Input pressure: 50 psig to 100 psig (3.45 bar to 6.9 bar)

|

| Electrical |

- Supply: 100 to 240 VAC ±10%, 50 or 60 Hz

- Maximum consumption: 1600W (dependent on instrument configuration)

|

| PC connection |

Ethernet |

| RoHS3 compliant |

Yes |

| CE / UKCA certified |

Yes |

| Indoor/outdoor use |

For indoor use only |