When over 40 years of experience in pressurized acid digestion meets sophisticated microwave technology, a high-performance microwave digestion system is created. The Multiwave 7101/7301/7501 series takes performance to the next level, functioning at temperatures up to 300 °C and up to 199 bar.

This provides thorough digestion of all samples, including food, environmental, polymer, cosmetic, pharmaceutical, geological, chemical, and petrochemical samples, even in the same run. With a variety of accessories, consumables, and racks with up to 41 places, sample preparation has never been simpler.

- 7101

- Easy to handle and digest

- Multiple backup safety systems

- All the advantages of a PDC system at a reasonable price

- Smart system for digestion of most samples

- Can be paired with an external cooler for additional savings

- 7301

- High operational parameters for excellent digestion results

- Software-guided procedures make the device simple to operate

- Integrated cooling system for a space-saving device

- A wide range of vials and vessels for all analytical issues

- Visual and digital status updates to keep in touch with the user

- 7501

- Special, software-guided cleaning protocols

- Preventive maintenance plan

- Heavy-duty device

- Upgraded for ultimate corrosion resistance

- Designed for aqua regia and HCl digestions

Key Features

One Microwave Digestion System for All Samples

Image Credit: Anton Paar GmbH

Digest a wide range of samples, including food, environmental, polymer, cosmetic, pharmaceutical, geological, chemical, and petrochemical ones, in one run using the same technique with Multiwave 7101/7301/7501. Elemental analysis is made easier by low blank values and low residual carbon content.

There is unlimited digestion performance due to the high temperature and pressure parameters (300 °C and 199 bar), and the magnetron output is automatically adjusted for reactive samples. Strong stirring facilitates the digestion of floating materials (optional).

Demanding Samples, Easy Digestion

Image Credit: Anton Paar GmbH

The sample preparation workflow is revolutionized by the PDC (Pressurized Digestion Cavity):

- Place the vials on the balance

- Transfer sample weights directly to the instrument

- Add digestion reagents and cover the vials with plug-on caps

- Safely transport the filled PTFE-TFM rack in a closed PTFE liner (<1 kg)

- Utilize software-guided, primarily automated opening and closing operations

- Count on automated pressurization, pressure release, and acid fume removal

- Pressure sealing of the vessels avoids cross-contamination

Microwave digestion systems provide ready-to-use techniques and customized application support, making method development easier than ever.

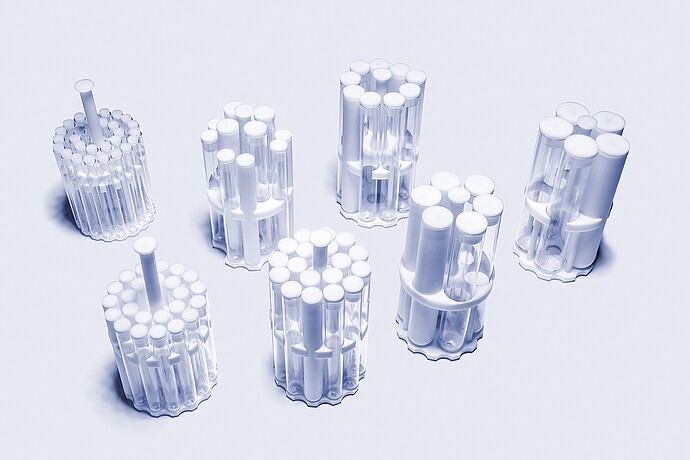

A Microwave Digestion System Fit for Any Analytical Task

Image Credit: Anton Paar GmbH

Multiwave 7101/7301/7501 microwave digestion devices can handle various PTFE-TFM racks, allowing users to microwave digest up to 41 samples in a single run and up to 4 g of sample in a single position. A variety of vials are available.

Users can employ thin-walled quartz vials with low blank values or disposable borosilicate vials for everyday activities. PTFE-TFM vials are offered for specialized applications. When working with volatile analytes, use only sealed quartz vessels.

Space-Saving and Safe

Image Credit: Anton Paar GmbH

Because of their small size, these microwave digestion devices save users lab space. The 7301 and 7501 Multiwaves save even more room since they include built-in water coolers. Multiple safety features, including fault-tolerant software, window shield, drip cup, and redundant safety systems, make Multiwave 7101/7301/7501 the safest microwave digestion system available.

Communicative and Compliant

Image Credit: Anton Paar GmbH

With the help of several smart features, such as automated email notifications of completed runs and events, users can stay informed and connected with their digestions. Using VNC, users can remotely control the instruments from a PC, tablet, or smartphone.

The instruments can access several standard procedures, including European Pharmacopoeia 5.20, ICHQ3D, and USP <232/233>. In addition to being compliant with CFR 21 part 11, the software comes with a comprehensive package of Pharma Qualification Documentation.

Multiwave 7501: For Demanding Samples

Image Credit: Anton Paar GmbH

If aqua regia digestion is conducted or if HCl is regularly used as a reagent, Multiwave 7501 is the answer. Updated components and extended automated cleaning methods have strengthened its corrosion resistance, allowing users to digest even the most demanding samples.

Technical Specifications

Source: Anton Paar GmbH

| |

Multiwave 7101 |

Multiwave 7301 |

Multiwave 7501 |

| Maximum power delivered |

1500 W |

1700 W |

1700 W |

| Installed power |

2000 W |

2000 W |

2000 W |

| Chiller |

external |

internal |

internal |

| SmartLight |

|

x |

x |

| Maximum temperature |

300 °C |

300 °C |

300 °C |

| Maximum pressure |

199 bar |

199 bar |

199 bar |

| HCl/Aqua regia digestions |

x |

x |

x |

| Balance connection |

|

x |

x |

| Liner lift |

x |

x |

x |

| Stirring option |

|

x |

x |

| VNC |

|

x |

x |

| Email notifications |

|

x |

x |

| Weight |

115 kg |

117 kg |

118 kg |

| WxDxH |

497 mm x 742 mm x 470 mm (19.5 in x 29.2 in x 18.5 in) |

615 mm x 760 mm x 470 mm (24.2 in x 29.9 in x 18.5 in) |