Anton Paar’s ViscoQC rotational viscometer provides convenient day-to-day operation in conjunction with the most reliable and traceable viscosity results. These rotational viscometers can ensure the quality of substances ranging from semi-solids to liquids.

Thanks to ViscoQC’s easy spindle exchange mechanism, automatic spindle detection functionality, automatic speed searching functionality for new formulations, and an array of other features, users can eliminate measurement errors while freeing up budgets and time.

Existing SOPs can also converted for use with this instrument, so long as the same settings and setup are used.

Key Features

The Most User-Friendly Rotational Viscometer

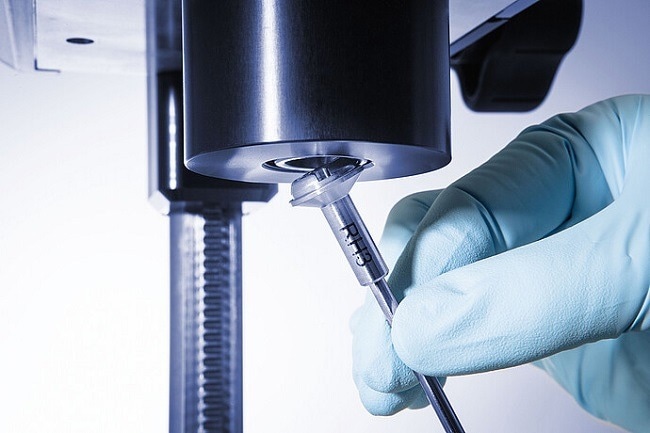

Image Credit: Anton Paar GmbH

Setup can be completed in less than two minutes, and users can simply unpack and measure because the ViscoQC comes preassembled and includes a helpful SOP booklet complete with easy-to-follow first steps and accessible user training.

Users are guided through the measurement process from startup via an intuitive and easy-to-follow user interface. It is possible to utilize the SOP methods of an existing rotational viscometer because the ViscoQC uses the same instrument setup and measuring settings to ensure identical results. All spindles are attached via magnetic coupling to ensure easy, fast, and safe exchange.

Full Traceability for Reliable Viscosity Tests

Image Credit: Anton Paar GmbH

Error-proof and fully traceable viscosity measurements are ensured with the unique Toolmaster™ feature. The viscometer automatically detects and documents attached spindles and accessories, and the ViscoQC 300 can even restrict each method to a specific spindle identity.

Built-in digital leveling functions automatically monitor leveling status and inform users in real-time. This prevents faulty measurements and ensures an impressive full-scale range accuracy of ± 1%.

Should a user need to measure new formulations, ViscoQC automatically directs them to the optimum spindle/speed configuration using the powerful TruMode™ functionality.

A Future-Proof Rotational Viscometer

Image Credit: Anton Paar GmbH

The ViscoQC’s functionality can be expanded with accessories to cover any requirement. These include:

- Heli-Plus: Used with non-flowing substances like gels, pastes, and creams

- PTD 80: Used for the rapidly and accurately control sample temperature between +15 °C and +80 °C

- PTD 100 Cone-Plate: Used with small sample volumes from 0.5 mL to 2 mL

- PTD 175: Used for high performance temperature control - a requirement when working with standards like ASTM D2983, D8210, D5133, 7110 and DIN 51398

- ETD 300: Used for high-temperature measurements of substances such as bitumen and hot melts, and when working with standards such as ASTM D4402 and AASHTO T316

Additional software functionality can be added to the ViscoQC 300 with V-Curve, enabling the use of real-time graphs, advanced analysis (such as yield point), improved programmability, and expanded method functionality.

Full Compliance Within One Day

Image Credit: Anton Paar GmbH

The ViscoQC is fully qualified and can be ready to use within just a single day while remaining fully compliant with 21 CFR Part 11, GMP, and GAMP 5. The V-Comply software provided with the ViscoQC 300 offers a range of useful features, such as an audit trail, electronic signature, and comprehensive qualification documentation.

More than a simple installation and basic IQ/OQ, the ViscoQC’s qualification involves an in-depth risk analysis, traceability matrix, performance qualification, and final qualification report. These powerful features improve the value of the qualification package for the whole process.

Generate and Export QC Data with Ease

Image Credit: Anton Paar GmbH

Each ViscoQC instrument includes the V-Collect PC-based data collection software.

The ViscoQC 100 does not store data on the device. Instead, results are directly exported or printed via the Brother QL-700 label printer upon test completion.

The ViscoQC 300 boasts 150 MB of memory—enough space to accommodate 999 measurements with up to 10,000 sub-measurements. Data can also be printed via a page printer (USB or network) or label printer or exported in CSV or PDF formats.

Users looking to leverage automated data export functionality can integrate the ViscoQC 300 into a network via a Laboratory Information Management System (LIMS) or an FTP server. The AP Connect platform can be used to connect instruments, communicate measurement information, and maintain compliance, effectively kickstarting fully paperless labs.

Maximum Uptime and Durable Parts

Image Credit: Anton Paar GmbH

The ViscoQC uses highly durable bearings and regularly performs an automatic bearing check (TruSine™). This powerful function maximizes uptime while minimizing ongoing service costs. All of the instrument’s spindles are manufactured from superior stainless steel (AISI 316L), protecting them from corrosion and improving spindle lifetime.

Technical Specifications

Source: Anton Paar GmbH

| |

ViscoQC 100 |

ViscoQC 300 |

| |

L |

R |

H |

L |

R |

H |

| Viscosity test |

Single-point |

Multi-point |

| Viscosity range [mPa.s or cP] (depends on measuring system) |

0.2* to 6 M |

1.6** to 40 M |

13.2*** to 320 M |

0.1* to 6 M |

1.3** to 40 M |

10.6*** to 320 M |

| Speed [rpm] |

0.1 rpm to 200 rpm

740 increments |

0.01 rpm to 250 rpm

Speed list with 18 standard speeds

Freely selectable speeds within the speed range |

| Max. spring torque [mNm] |

0.0673 |

0.7187 |

5.7496 |

0.0673 |

0.7187 |

5.7496 |

| Accuracy |

±1.0 % full scale range |

| Repeatability |

±0.2 % full scale range |

| Heli-Plus compatibility |

✔ |

| PTD 100 Cone-Plate compatibility |

✔ |

| ETD 300 compatibility |

✔ |

| Peltier temperature control |

+15 °C to +80 °C (for DIN/SSA with PTD 80)

0 °C to + 100 °C (for CP with PTD 100 Cone-Plate) |

+15 °C to +80 °C (for DIN/SSA with PTD 80)

-45 °C to +175 °C (for DIN/SSA/UL/4B2/L1D22 with PTD 175)

0 °C to + 100 °C (for CP with PTD 100 Cone-Plate) |

| Electrical temperature control |

+25 °C to +300 °C (for SSA/DIN with ETD 300) |

| Liquid temperature control/sensing |

Ambient to +100 °C (control of L/RH spindles with optional thermostat bath) |

| Temperature sensing |

-60 °C to +300 °C (temperature sensing with optional Pt100) |

| Intuitive user interface |

3.5" color LCD display |

7" color touchscreen display;

Options: keyboard, mouse, 2D bar code reader |

| Languages |

EN, DE, ES, FR, CN, JA, KO, IT, RU, PT |

EN, DE, ES, FR, IT, PT, JA, KO, RU, ZH-CN, ZH-TW, PO, CZE |

| Built-in digital leveling |

✔ |

| Easiest spindle exchange (magnetic coupling) |

✔ |

| Automatic spindle recognition (Toolmaster™) |

✔ |

| Automatic measuring range calculation |

✔ |

| Automatic speed searching function (TruMode™) |

✔ |

| Spindle correction by user |

✔ |

| Users, user groups |

None |

✔ Customizable |

* With optional PTD 100 Cone-Plate, with L1 spindle 15 mPa.s

** With optional PTD 100 Cone-Plate, with RH1 spindle 100 mPa.s

*** With optional PTD 100 Cone-Plate, with RH1 spindle 800 mPa.s

M = million

DIN = Concentric cylinders, double-gap

SSA = Small sample adapter (SC4-xx)

UL = Ultra-low viscosity adapter

Standards

AASHTO

ASTM

| D115 |

D789 |

D1076 |

D1084 |

D1337 |

D1338 |

D1417 |

D1439 |

| D1824 |

D1986 |

D2196 |

D2243 |

D2364 |

D2493 |

D2556 |

D2983 |

| D3236 |

D3288 |

D3468 |

D3716 |

D3730 |

D3791 |

D3794 |

D4016 |

| D4143 |

D4300 |

D4402 |

D4682 |

D4878 |

D4889 |

D5018 |

D5133 |

| D5324 |

D5400 |

D6080 |

D6114 |

D6158 |

D6267 |

D6279 |

D6577 |

| D7110 |

D7394 |

D7395 |

D8020 |

D8162 |

D8210 |

E2975 |

E3070 |

| E3116 |

F1607 |

F3208 |

|

|

|

|

|

BS

Chinese Pharmacopoeia (ChP)

- 0633 Rotational viscosity measurement method, method III

DIN

- 2555

- 3219

- 13302

- 16945

- 51398

- 52007-1

- 53019-1

- 54453

EN

- 302-7

- 2555

- 3219

- 10301

- 12092

- 12802

- 15425

- 15564

ISO

- 1652

- 2535

- 2555

- 2884

- 3219

- 8003

- 10364-12

Japanese Pharmacopoeia (JP)

- XVII 2.53 (2.1.2) Single cylinder-type rotational viscometer

Pharmacopoeia Europe (Ph. Eur.)

- 2.2.10 - Rotating viscometer method

TAPPI

U.S. Pharmacopoeia (USP)

- 912 Rotating viscometer method