Litesizer DIF delivers high-precision particle size measurements from 10 nm to 3.5 mm, using nearly six decades of Anton Paar's laser diffraction know-how.

This laser diffraction particle size analyzer is equipped with a best-in-class optical configuration, enabling highly accurate and reliable results. For users who require more detailed morphology information, an optional image analysis module supports additional shape analysis and dependable identification of oversized particles.

The Kalliope software streamlines particle sizing workflows, allowing users to initiate measurements with just three clicks, eliminating the need for extensive training. With the Quick-Click system, users can switch between dispersion units with ease, reducing the likelihood of handling errors. Integrated safety mechanisms for both liquid and dry dispersion modes support smooth, secure operation.

A rugged metal enclosure combined with an isolated optical bench ensures dependable performance in a wide range of settings, from demanding industrial environments to advanced research laboratories.

Building on a long-standing tradition of innovation, this next-generation laser diffraction solution sets a new standard in the field. Litesizer DIF: From First to Best.

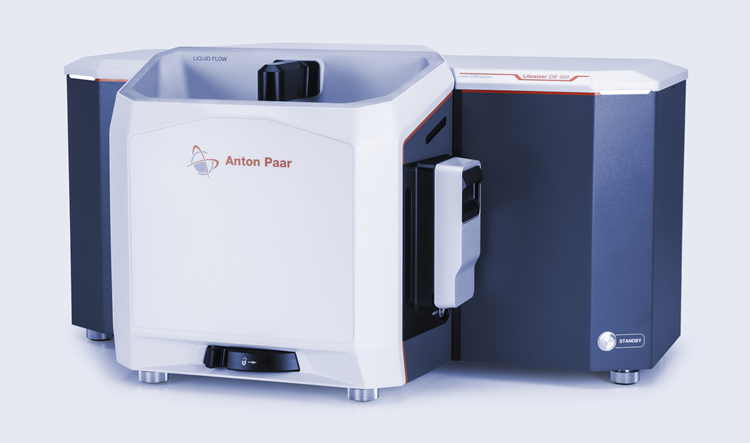

Litesizer DIF 500

Image Credit: Anton Paar GmbH

- Image analysis module available for additional shape analysis

- Measure samples from 0.01 µm to 3,500 µm

- Switch between liquid and dry dispersion in just one move

- Kalliope software: No training required, dedicated QC mode

Litesizer DIF 300

Image Credit: Anton Paar GmbH

- Kalliope software: No training required, dedicated QC mode

- Measure samples from 0.1 µm to 2,500 µm

- Switch between liquid and dry dispersion in just one move

- Image analysis module available for additional shape analysis

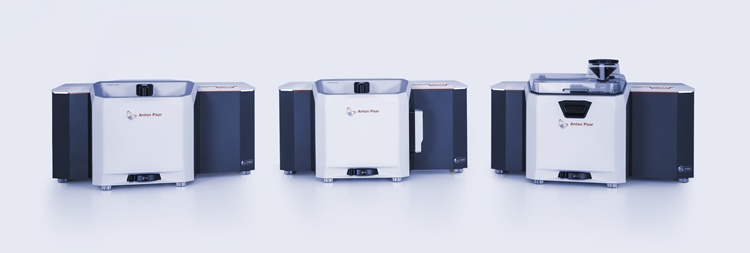

Litesizer DIF 100

Image Credit: Anton Paar GmbH

- Kalliope software: No training required, dedicated QC mode

- Measure samples from 0.1 µm to 1,000 µm

- Switch between liquid and dry dispersion in just one move

Key Features

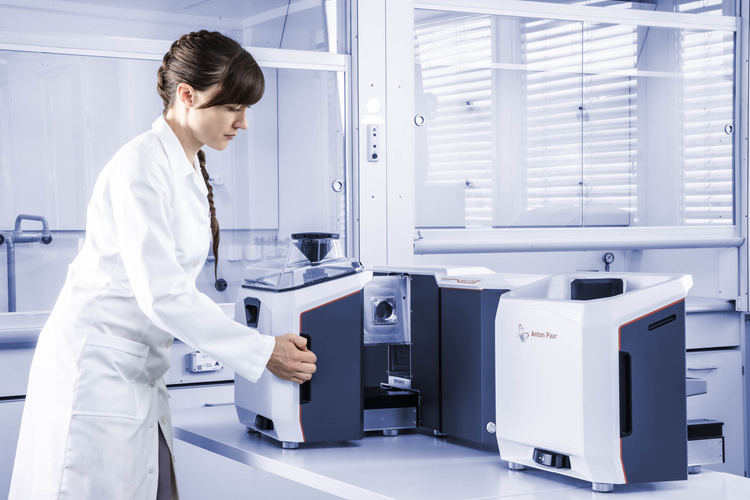

On Quality, Anton Paar Leads the Way

Image Credit: Anton Paar GmbH

Litesizer DIF stands out as a particle analysis solution, thanks to its premium build quality. High-grade hardware components enable the instrument to capture superior raw data. Litesizer DIF 500 supports a very broad measurement range, covering particle sizes from 0.01 µm to 3,500 µm. Litesizer DIF 300 and Litesizer DIF 100 focus on narrower ranges, making them ideal for targeted analysis of specific size distributions.

All Litesizer DIF analyzers have a 10-year warranty on lasers

Kalliope: The Benchmark Software for Particle Sizing

Image Credit: Anton Paar GmbH

Kalliope guides users intuitively through the entire process via a single-page workflow that covers parameter setup, data acquisition, and result evaluation. In addition, QC mode ensures consistent, reproducible measurements by allowing customized user management and locking of critical settings.

When the instrument runs in QC mode, it provides straightforward feedback on whether a product lies within predefined limits. This enables a three-click operation, reducing training time for new users. A dedicated pharma option with data security features, user management, and audit trails is also available, ensuring that Kalliope meets the requirements of the US FDA’s 21 CFR Part 11.

Efficient Dispersion, Maximum Safety

Image Credit: Anton Paar GmbH

With the Litesizer DIF Quick-Click interface, dispersion units are connected in a single motion – eliminating the need to deal with separate cables, tubes, or pipes. During sample addition, the obscuration level indicator helps users track the amount of material being introduced, so the correct concentration is achieved from the outset. The dispersion units are engineered with safety as a priority:

The Dry Jet dispersion unit features a suction check and an integrated dust cover, designed to reduce the risk of powder escaping. The Liquid Flow dispersion unit automatically verifies that there is sufficient liquid before sonication begins, protecting the system from overheating.

Particle Sizing in Any Environment

Image Credit: Anton Paar GmbH

Anton Paar’s Litesizer DIF is designed for use in both heavy industrial settings and laboratories. High-quality internal and external components, together with a 10-year warranty on the lasers, contribute to long-term reliability.

Metal housing protects the optical components, while the optical bench is sealed against dust and powder ingress. The internal structure is also isolated from direct vibrations that may occur at production sites. These design choices help users reduce maintenance and repair expenses over the instrument’s lifetime.

Sharper Results with Image-Enhanced Diffraction

Image Credit: Anton Paar GmbH

Litesizer DIF can be upgraded with image analysis capabilities, providing deeper insight into particle shape and enabling the detection of individual oversized particles. Dispersion units are compatible between Anton Paar’s Litesizer DIA and Litesizer DIF instruments, which helps users lower investment costs and optimize laboratory space. Furthermore, all Litesizer instruments can be controlled from a single PC running the Kalliope software.

Specifications

Source: Anton Paar GmbH

|

Litesizer DIF 500 |

Litesizer DIF 300 |

Litesizer DIF 100 |

| Measurement principle |

Laser Diffraction (Mie and Fraunhofer scattering) |

| Measurement range |

0.01 μm - 3,500 μm |

0.1 μm - 2,500 μm |

0.1 μm - 1,000 μm |

| Size classes |

144 (user adjustable) |

114 (user adjustable) |

104 (user adjustable) |

| Accuracy * |

better than ± 0.5 % variation*** |

| Repeatability |

better than ± 0.5 % variation*** |

| Reproducibility** |

better than ± 1 % variation*** |

| Typical measurement duration |

< 10 sec |

| Data acquisition rate |

16 kHz |

| Light source 1 |

|

| Type |

Fiber-coupled laser diode |

| Optical arrangement |

Reverse Fourier setup |

| Wavelength |

830 nm, infrared |

| Laser power |

10 mW |

| Laser class |

Class 1 (IEC60825-1) |

| Light source 2 |

Litesizer DIF 500 |

- |

| Type |

Laser diode |

- |

| Optical arrangement |

Tilted relative to the IR laser |

- |

| Wavelength |

450 nm, blue |

- |

| Laser power |

25 mW |

- |

| Laser class |

Class 1 (IEC60825-1) |

- |

| Detectors |

|

| Type |

Log-spaced photo diode array and single diodes for side and back-scattering |

| Angular range |

0.01 ° - 170 ° |

0.01 ° - 155 ° |

|

| Focal length |

300 mm |

| Alignment |

Automatic |

| Instrument data |

|

| Instrument dimensions**** |

400 mm x 790 mm x 290 mm (H x W x D) |

| Instrument weight**** |

42.3 kg (93.2 lb) |

| Power supply |

100 V to 240 V ±10 %, 50/60 Hz |

Trademarks: Kalliope (EU: 012709391, UK: UK00912709391), Litesizer (EU: 011695491, UK: UK00911695491)

* Defined for a monomodal latex standard and accounting for the manufacturer's uncertainty of standard size.

** Defined for D50 of a polydisperse standard.

*** Sample and preparation dependent. Defined for liquid dispersion measurements.

**** Without PC and dispersion unit