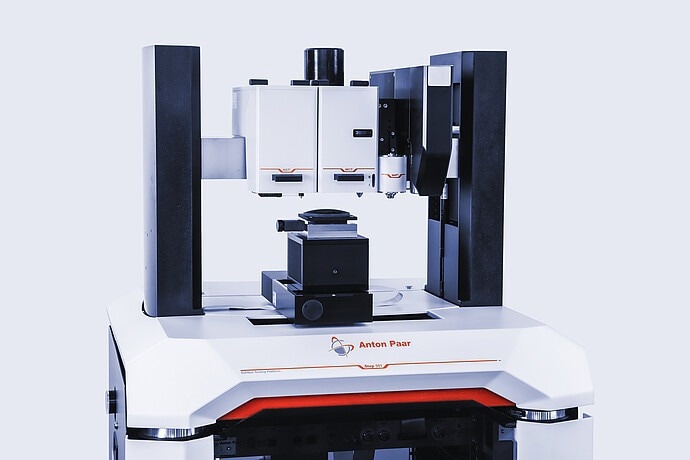

The Nano Scratch Tester (NST3) is ideal for determining the scratch resistance and adhesion of thin films and coatings with average thicknesses below 1000 nm. Analyze organic, inorganic, soft, and hard coatings. The nano-scratch measurement head’s innovative design contains two sensors for force and depth measurements and a cutting-edge piezoelectric actuator, allowing for results in milliseconds with high precision and versatility.

Image Credit: Anton Paar GmbH

Combine the NST3 head with another scratch or indentation testing head to cover the nano, micro, and macro range. The Step platform’s adaptability allows users to use an AFM to explore surface topography.

- Evaluation of coating adherence and scratch resistance

- The whole panorama image is synced with all other signals, including penetration depth and friction force

- Perfect for thin coatings less than 1000 nm in thickness

- Force measurement up to 1000 mN

Image Credit: Anton Paar GmbH

Key Features

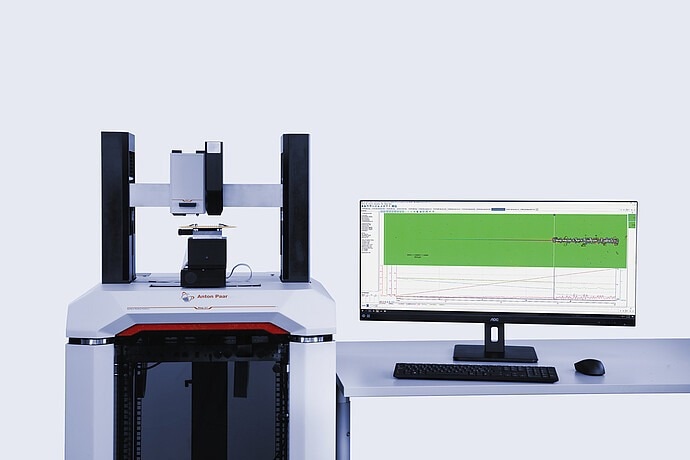

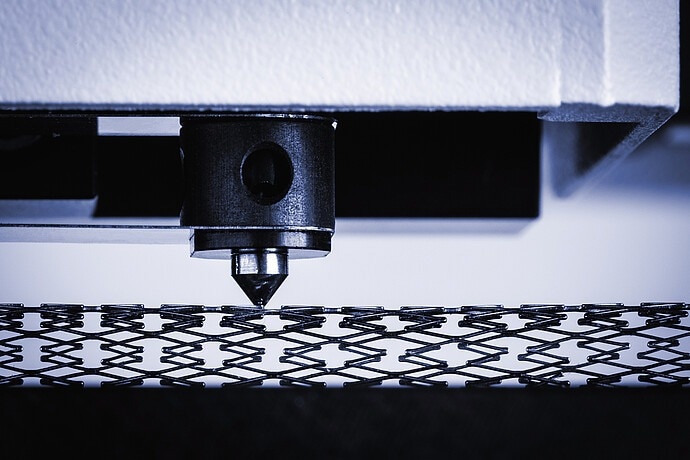

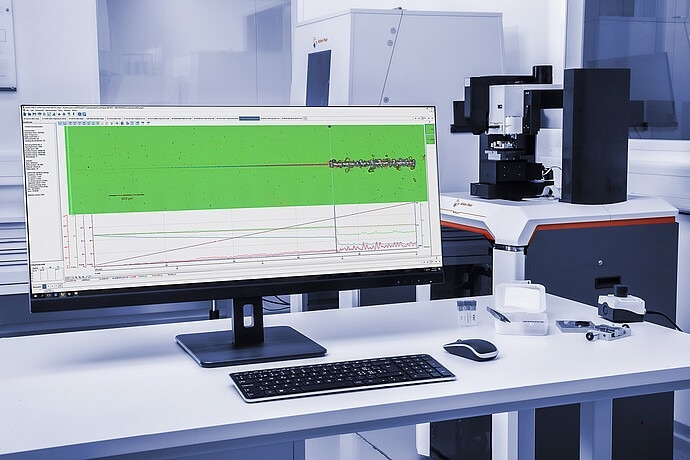

Full Synchronized Panorama for Analysis Whenever, Wherever

Image Credit: Anton Paar GmbH

This unique feature of the Nano Scratch Tester instantly synchronizes a panoramic image of the whole scratch in perfect focus with scratch data collected from all sensors. Using panorama observations and signal recordings, you can perform a critical load analysis at any time. Anton Paar owns the synchronized panorama technology (US patent 8261600 and European patent EP 2065695).

Fast Small-Force Response

Image Credit: Anton Paar GmbH

The Nano Scratch Tester combines a double cantilever beam for load application with a piezoelectric actuator for an ultra-fast response (milliseconds) to the applied load. This idea also accounts for variations induced by any event during the scratch (for example, the formation of cracks and failure, flaws, or a non-flat sample).

Apply Exactly the Force Customers Want

Image Credit: Anton Paar GmbH

The closed active force feedback loop ensures precise nano scratch testing (normal load resolution of 0.01 µN and noise floor of 0.1 µN). The NST³ contains a real force sensor that feeds straight to the conventional force actuator. This allows consistent scratch testing, especially when investigating more difficult surface geometries such as non-parallel, abrasive, or curved materials.

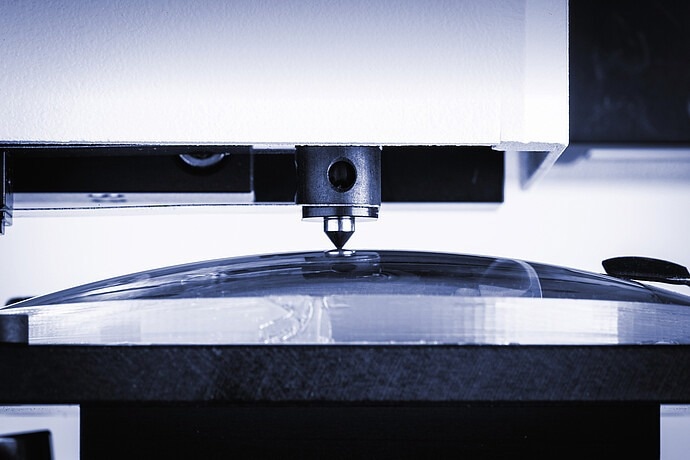

Elastic Recovery Studies: True Penetration Depth Measurements

Image Credit: Anton Paar GmbH

The NST³ Nano Scratch Tester has a displacement sensor to track the indenter's vertical motion. The unique pre- and post-scan approach yields true depth, allowing the study of materials' elastic, plastic, and viscoelastic characteristics.

Before the scratch test, a pre-scan of the sample’s surface profile (form, waviness, and roughness) is performed. NST³ uses the surface profile to regulate indenter depth during and after the scratch (penetration and residual depth).

Multi-Post-Scan Mode to Measure Viscous Behavior After a Scratch

Image Credit: Anton Paar GmbH

After a scratch, the software allows users to create infinite post-scan measurements with a time delta to determine residual depth. This new study will offer users an enhanced understanding of the surface’s deformation behavior against recovery time.

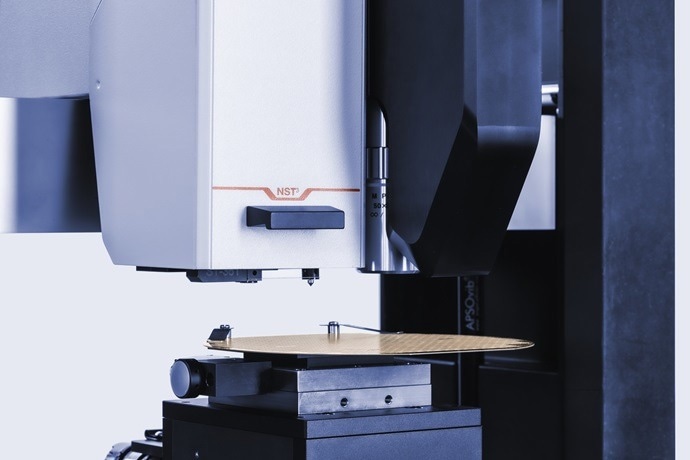

Added Versatility with the Step Platform

Image Credit: Anton Paar GmbH

The Step platform is a complete solution for surface mechanical characterization testing. Whether users wish to conduct only scratch tests or supplement the data with indentation and AFM measurements, the Step platform always provides the best solution in terms of adaptability, stability, and noise isolation.

Technical Specifications

Source: Anton Paar GmbH

| . |

. |

| Maximum load [mN] |

1000 |

| Load resolution [μN] |

0.01 |

| Load noise floor [rms] [μN] |

0.1 |

| Loading rate [N/min] |

Up to 100 |

| Maximum friction force [mN] |

1000 |

| Friction force resolution [μN] |

1 |

| Maximum depth [μm] |

600 |

| Depth resolution [nm] |

0.1 |

| Depth noise floor [rms] [nm] |

1.5 |

| Data acquisition rate [kHz] |

192 |

| Scratch speed [mm/min] |

0.1 to 600 |