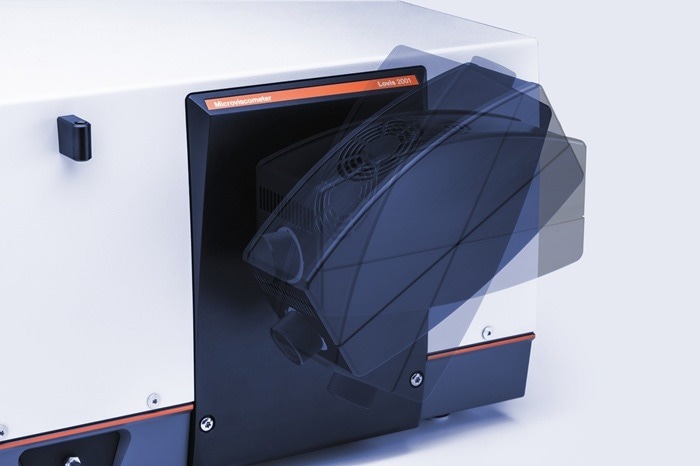

The Lovis 2001 is an innovative rolling-ball micro viscometer based on Hoeppler’s falling ball principle. Its adjustable measurement angle delivers exceptional precision, especially when analyzing low-viscosity or shear-sensitive liquids. With minimal sample volume, it provides polymer-specific parameters - such as intrinsic viscosity, K-value, and average molar mass - in as little as 30 seconds to three minutes.

Equipped with a Peltier thermostat, the Lovis 2001 ensures fast, energy-efficient temperature control across a wide range (5 °C to 100 °C), delivering reliable results for various sample types. For even greater flexibility, it can be configured to operate at temperatures as low as –40 °C (–40 °F), making it an adaptable solution for modern laboratories.

Lovis 2001 Benchtop

Image Credit: Anton Paar GmbH

- The viscosity of a sample is measured using a falling ball viscometer with an adjustable angle

- Provides the average molar mass, K-value, inherent viscosity, and more

- Referenced in US Pharmacopoeia chapter 913 and Ph. Eur. 2.2.49

- Automated filling and cleaning through sample changer

- Combine to measure the refractive index and pH in one go

Lovis 2001 Module

Image Credit: Anton Paar GmbH

- Combination with the DMA density meter

- Kinematic and dynamic viscosity combined in a single measurement cycle

- Referenced in US Pharmacopoeia chapter 913 and Ph. Eur. 2.2.49

- Wort: MEBAK- (R-205.10.282) and ASBC- (Wort-13B) compliant

- Optional pH, refractive index, and sample changer

Key Features

A Falling Ball Viscometer with Adjustable Inclination Angle for Maximum Precision

Image Credit: Anton Paar GmbH

To ensure the best measurement precision, the movable capillary block covers an angle range of 15° to 80° in either direction. While fast-falling balls in standard falling-ball viscometers cause turbulent flow in low-viscous liquids, a rolling ball with a speed tailored for the sample type does not.

Lovis 2001 also lets users test shear-sensitive materials and shows the shear rate. Without requiring several systems, the device monitors dynamic viscosity in the range of 0.2 mPa·s to 10,000 mPa·s, covering a variety of applications. Since it uses electromagnetic detection, it is not impacted by the turbidity or opacity of the sample.

Combine for a Superior Measurement System

Image Credit: Anton Paar GmbH

Make use of modularity to ensure a smooth and effective measurement procedure. Using a density input, Lovis 2001 quickly computes dynamic and kinematic viscosity and measures runtime, relative and intrinsic viscosity. The sophisticated falling ball viscometer uses an autosampler to measure the sample in a time-saving flow-through mode without requiring operator intervention.

Upgrade to other measurement units, such as density, pH, or refractive index, which can be easily measured in a single measuring cycle. The AP Connect lab execution system can help to centralize and streamline data administration.

Full Compliance with Industry Standards

Image Credit: Anton Paar GmbH

Lovis 2001 guarantees complete data integrity and complies with all 21 CFR Part 11 criteria. Measure according to US Pharmacopoeia chapter 913 and Ph. Eur. 2.2.49. Measure specific gravity according to <841> and relative density according to Ph. Eur. 2.2.5 in addition to the well-known DMA density meter.

The extra AISQ+ documentation for regulated industries allows users to complete instrument qualification and validation in only one day. Lovis 2001, when combined with a density meter, measures wort in accordance with MEBAK and ASBC requirements.

Falling Ball Viscometer with Integrated Polymer Software

Image Credit: Anton Paar GmbH

The adjustable falling ball viscometer’s integrated software calculates and reports metrics, including relative viscosity, specific viscosity, decreased viscosity, inherent viscosity, intrinsic viscosity, K-value, and average molar mass for polymers. This method of automating polymer analysis eliminates the error-prone usage of external equipment. Results are stored in a database for further comparison.

Measure Aggressive Chemicals without Risk

Image Credit: Anton Paar GmbH

The hermetically closed system allows users to easily measure volatile or hazardous samples while protecting delicate samples from contamination. While the borosilicate glass capillaries can handle most solvents and acids, the break-proof PCTFE capillaries with a gold-coated ball and FFKM O-rings allow users to test compounds as harsh as hydrofluoric acid.

Using narrow capillaries with sample sizes as little as 100 μl can reduce waste and operational expenses for valuable or restricted samples. After measurement, the sample can be recovered for additional testing, lowering the overall cost of the experiment.

Technical Specifications

Source: Anton Paar GmbH

| |

Lovis 2001 |

Lovis 2001 Module + DMA density meter |

| MEASURING RANGE |

|

|

| Dynamic viscosity |

0.2 mPa·s to 10,000 mPa·s |

| Shear rate |

0.5 s-1 to 1000 s-1 |

| Temperature |

5 °C to 100 °C (41 °F to 212 °F)

-40 °C to 100 °C (-40 °F to 212 °F) (with counter cooling)1) |

| Density |

- |

0 g/cm³ to 3 g/cm³ |

| Temperature: Density |

- |

0 °C to 100 °C (32 °F to 212 °F) |

| PRECISION |

|

|

| Viscosity: Repeatability s.d. |

0.1 % 2) |

| Viscosity: Accuracy |

0.5 % 3) |

| Measuring time: Resolution |

0.001 s |

| Measuring time: Accuracy |

0.05 % |

| Temperature: Repeatability s.d. |

0.005 °C |

| Temperature: Accuracy |

0.02 °C |

| Inclination: Repeatability s.d. |

0.02 ° |

| Inclination: Accuracy |

0.1 ° |

| FURTHER SPECIFICATIONS |

|

|

| Test duration |

Minimal 30 s, typical 3 min |

| Sample volume |

0.1 mL to 0.8 mL |

1 mL to 3 mL |

| Weight |

19.9 kg (43.9 lb) |

29.3 kg (64.6 lb) |

| Dimensions (L x W x H) |

526 mm x 420 mm x 230 mm (20.7 in x 17.2 in x 9 in) |

| Power supply |

AC 100 V to 240 V; 50 Hz to 60 Hz; 190 VA |

| Trademarks |

DMA (013414867), Xsample (013856059), Abbemat (1084545) |

1) Specified temperatures are valid for a max. ambient temperature of 35 °C (95 °F). Lower measuring temperatures are achieved in lower ambient temperatures and/or with special equipment.

2) Verified with a 1.59 capillary at 70° angle and Ethanol 96 % at 20 °C using the same ball for all repeated measurements.

3) Verified with a 1.59 capillary with a single-point adjustment performed on site at 70° angle; adjustment and all measurements performed with distilled water at 20 °C with the same ball.