Because of their low dimensionality, adaptability, and resilience, van der Waals (vdW) substances have piqued the interest of the microelectromechanical systems (MEMS) congregation.

Graphene, specifically, is regarded as the substance for the next era of sensor systems due to its inherent material properties.

The deformation of a tissue caused by the differential pressure between a benchmark chamber and the surroundings is measured by pressure devices.

Gas permeability along the interaction between both the van der Waals cell wall and the cellulose creates pressure fluctuations in the reference chamber, making graphene-based pressure gauges inadequate.

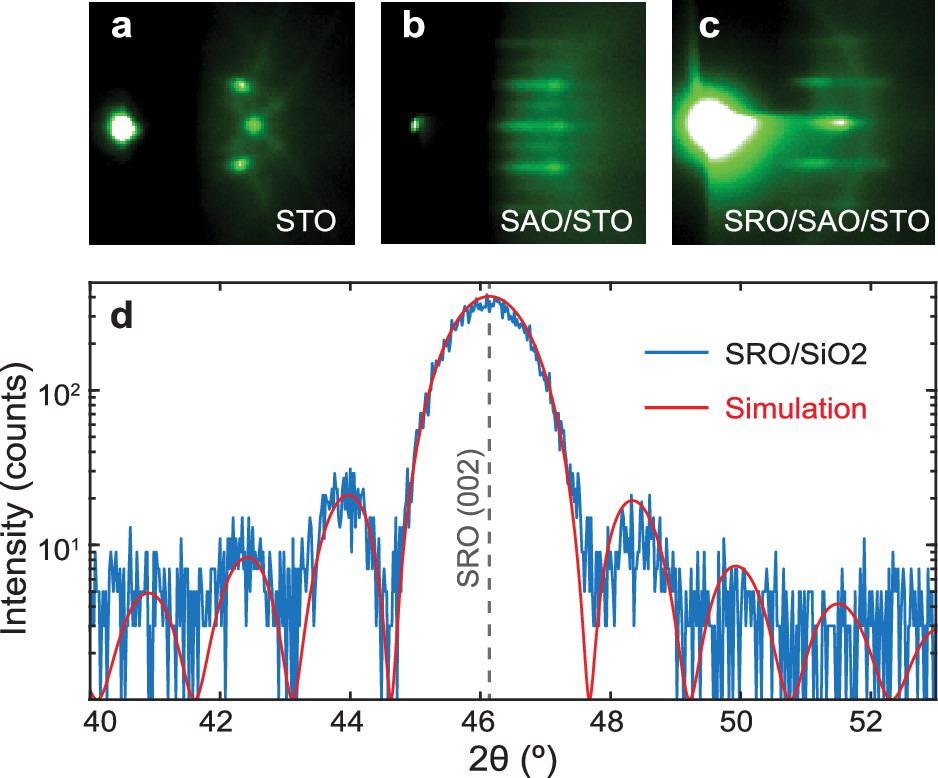

Figure 1. Reflection high-energy electron diffraction (RHEED) images of (a) SrTiO3 (STO) substrate, (b) Sr3Al2O6 (SAO) grown on STO substrate, and (c) SrRuO3 grown on SAO/STO stack. (d) X-ray diffraction (blue) of exfoliated SRO stamped on SiO2/Si and the simulation (red). The c-axis lattice parameter extracted from the simulation is 3.931 Å, and the thickness is 16 unit cells. © Lee, M., Robin, M. P., et al. (2022)

Disadvantages of van der Waals Materials

In this report, single free complicated oxide perovskites as a tissue for microelectromechanical systems applications as a substitute to graphene is implemented.

Complicated oxides can form a covalent bond with the membrane at extreme temps, apart from van der Waals materials, that are essentially at a disadvantage due to the unavoidable consequence of the sluggish van der Waals engagement with the material.

As a result, complicated oxides offer better bonding to the membrane than 2D materials. For instance, single structural oxides like LiNbO3 have been shown to reconnect straight onto other substances such as Si1 utilizing direct wafer bonding (DWB) to generate submicron silky microelectromechanical systems reflectors.

Furthermore, because of their epitaxial crystallization expansion, exceptionally unified surfaces are risen using pulsed laser deposition (PLD), improving connectivity and decreasing the likelihood of gas leakage routes forming.

New progress in the release of epitaxially grown single-crystal complicated oxides enables them to be trimmed down to the unit cell threshold, comparable to van der Waals components.

Complicated oxides in their extremely thin free-standing shape are mechanically strong, enduring strains of up to 8%, are able to allow huge curves, and have already been illustrated to be feasible nanoscale transceivers.

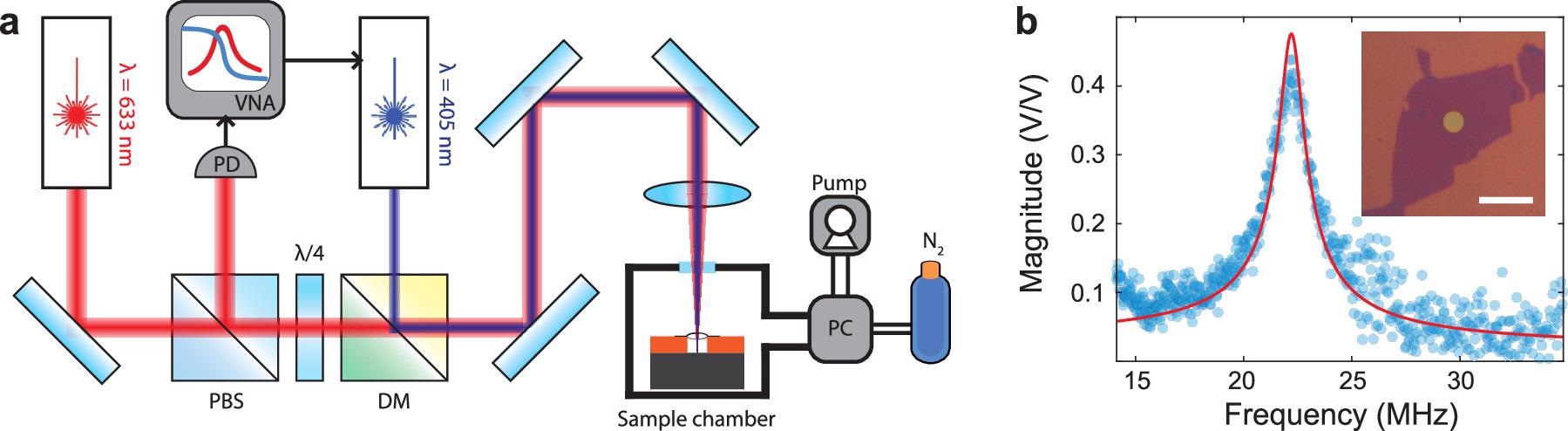

Figure 2. (a) Schematic illustration of the measurement setup. Vector network analyzer (VNA) sends an amplitude modulated signal to the blue laser diode which optothermally actuates the membrane while the red He–Ne laser reads out its motion. The reflected red laser light is detected at the photodetector (PD) and the signal is collected by the VNA. The pressure inside the sample chamber is controlled by the pressure controller (PC) which is connected to a scroll pump and a pressurized N2 gas bottle. PBS, polarized beam splitter; DM, dichroic mirror. (b) An example of a resonance peak of a SRO (16 u.c.) device with a harmonic oscillator fit in red. Inset: optical image of the device. A SRO flake is stamped on top of a circular cavity in SiO2/Si. Scale bar is 10 μm. © Lee, M., Robin, M. P., et al. (2022)2)

Applied Techniques

Strain gauges were made out of available SrRuO3 (SRO) and SrTiO3 (STO) dissolved over SiO2/Si pores.

A straightforward, CMOS suitable gasket technology similar to DWB was illustrated that does not demand any extra manufacturing stages.

The gadgets were sealed by annealing them at temperatures above 300 °C in environmental conditions for 15 minutes. The pervaporation time constant was calculated by measuring the time reliance of the resonant frequencies.

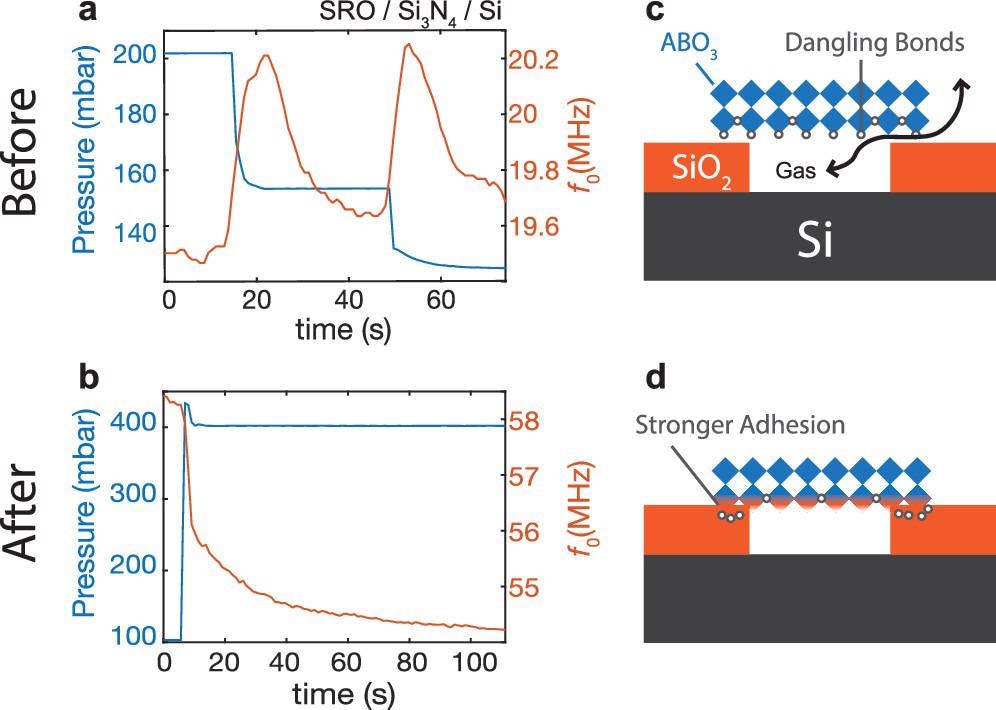

It was demonstrated that the permeability settling time of the pressure sensing devices rises from 14 s to >10 000 s after conducting the self-sealing annealing procedure, indicating a significant rise in hermeticity.

Similar gadgets manufactured on Si3N4/Si pores do not exhibit such an improvement in hermeticity, implying that the optimized hermeticity is facilitated by SiO2 characteristics that promote adhesion to complicated oxides, thereby eradicating gas leakage percentages.

Moreover, a picosecond ultrasonics method was used to investigate the STOSiO2 functionality in both heat-treated and nonannealed specimens.

The measured values demonstrated a large decrease in the ultrasonic radiation pattern at the interaction of STO-SiO2 after heat treatment, indicating increased adherence.

This research also looked at the use of an extremely thin complicated oxide membrane surface for sensing elements and showed that the interaction self-seals after the transmission, supplying a substitute to graphene and microelectromechanical systems monitoring devices.

Figure 3. Pressure response (left y-axis, blue) of mechanical resonance (right y-axis, orange) in a SRO device fabricated on 350 nm Si3N4/Si (a) before annealing and (b) after annealing. Possible mechanism of the bonding is illustrated in panels c and d. (c) Before annealing, there are dangling bonds at the bottom of the flakes. The vdW gap between the SRO and the SiO2 allows for gases to pass through. (d) After annealing, vacancies bond with the oxygen in the substrate leading to a stronger bond to form at the interface. © Lee, M., Robin, M. P., et al. (2022)

Concluding Remarks

In conclusion, the use of loose complicated oxides SrRuO3 and SrTiO3 was explored for pressure sensor applications and displayed an annealing-based self-sealing approach to enhance hermeticity.

Gases propagate the van der Waals substrate functionality, and eliminating this permeability route is critical for manufacturing upcoming strain gauges.

Significant progress was made towards this objective by encouraging better adherence to structure at the interaction of complicated oxides and SiO2.

Advancements in the pervaporation time constant and the comparison in the absorption coefficient at the interaction recommend that heat treatment strengthens the interface bonding of complicated oxides (SrRuO3 and SrTiO3) and SiO2.

The impacts of the material on interfacial bonding were studied even more by conducting permeability metrics on Si3N4/Si gadgets.

Because major gains in time constant were only seen on SiO2 surfaces, it was probable that the oxygen atoms on the SiO2 surface layer played an essential part in facilitating adherence.

The findings of this research were a first move toward using free-standing complicated oxides as a replacement for silicon and two-dimensional components in next-generation microelectromechanical systems sensing devices.

Reference

Lee, M., Robin, M. P., et al. (2022). Self-Sealing Complex Oxide Resonators. Nano Letters. Available at: https://pubs.acs.org/doi/10.1021/acs.nanolett.1c03498

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.