A team of researchers recently published a paper in the journal Materials Today: Proceedings that investigated the effect of different carbon nanotube (CNT) nanofiller concentrations on the impact and mechanical properties, specifically the ballistic performance, of epoxy/Kevlar composites.

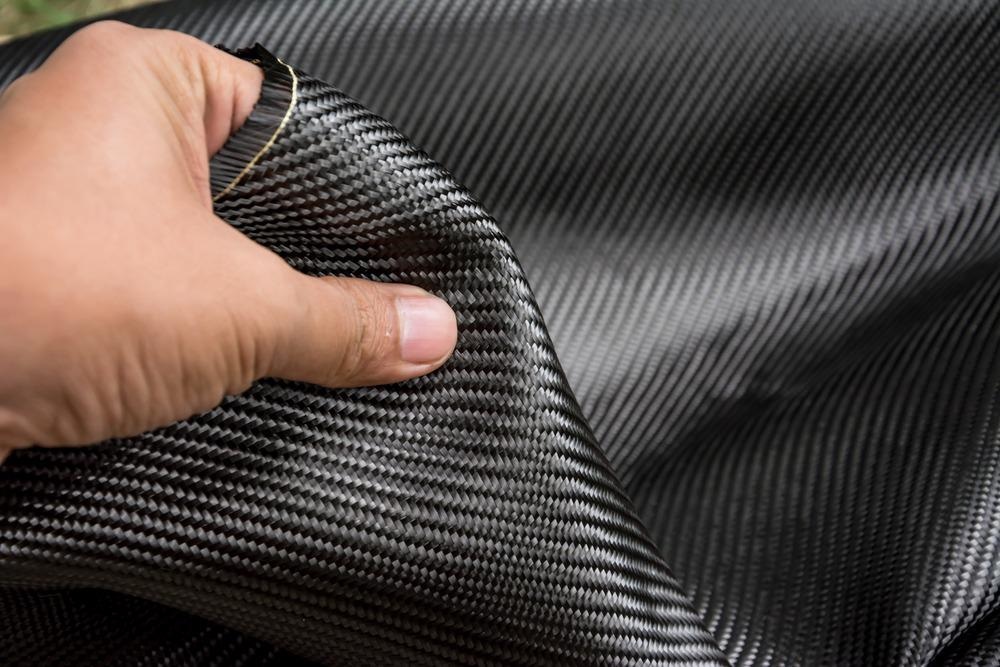

Study: Ballistic performance of nanopowder intruded Kevlar polymeric composite targets. Image Credit: Composite_Carbonman/Shutterstock.com

Limitations of Existing Resin/Fiber Composites

‘Terminal ballistics’ is typically an area of importance and concern in several applications in the defense sector. Among these applications, body armor has gained prominence in terms of the range of use and expenditure. Currently, research is focused on composites that hold significant potential for application in modern body armor as they have a flexible fiber reinforcement phase, a rigid matrix phase, and fillers that improve interactions between these phases.

Kevlar, a lightweight fiber, is often preferred for high tensile and high toughness applications in defense and aerospace industries owing to its impressive properties that are attributed to its molecular arrangement and production methodology. Kevlar fiber mats are typically utilized in soft armor panels (SAP) as well as hard armor panels (HAP).

Epoxy resin is considered to be a suitable polymer matrix for modern body armors due to its superior thermal properties, exceptional chemical resistance, and high adhesive bonding. However, the brittle nature of the resin matrix limits its application in high toughness applications. Hence, the properties of both reinforcement fiber and the matrix must be improved to better the overall effectiveness of composite fibers.

Importance of Nanofillers to Improve Epoxy/Kevlar Composite Properties

Nanofillers can enhance the interactive properties of fibers and the matrix through surface-level bonding. Additionally, these substances can act as a resistance to brittle fracturing. Multi-walled carbon nanotubes (MWCNTs) are more suitable among the various synthetic and natural nanofillers owing to their superior electrical, thermal, and mechanical properties. Moreover, the high aspect ratio of CNTs makes them suitable for improving the overall composite properties.

A lower addition of CNT to epoxy resins can significantly improve the fracture toughness, tensile modulus, and tensile strength of the matrix. However, a higher addition of CNT in the matrix leads to agglomeration owing to a high Vander Waals force of attraction. Thus, higher CNT addition causes little improvement in the overall matrix properties.

Hence, the effect of different CNT concentrations on the impact and mechanical properties must be evaluated to develop an effective epoxy/Kevlar composite.

Synthesis and Evaluation of Epoxy/Kevlar Composites with Different Nanofiller Concentrations

In this study, researchers synthesized three epoxy/fiber composites, one without CNT nanofillers and two with nanofillers, and evaluated the synthesized samples in terms of tensile strength, interlaminar shear stress (ILSS), and ballistic performance. A gas gun setup was used to determine the ballistic behavior of the synthesized composites.

Hardened conical projectiles with 10 millimeters in diameter and 7.85 grams in weight were used to create the low-velocity ballistic impact on the composites during the ballistic performance evaluation. Researchers also performed a fractographic study of the fabricated samples.

MWCNTs with sizes between 10 and 20 nanometers and lengths more than 10 micrometers, a simple 250 grams per square meter plain weave Kevlar mat, a bisphenol-A type epoxy, an Aradur hardener, and ethanol were used as the starting materials for the study. The received nanofillers were processed before using them in composite preparation, as a high degree of agglomeration was observed in these CNTs which can adversely impact the final composite properties.

A specific amount of CNT was mixed with ethanol, and the mixture was probe sonicated with a water bath for over an hour to achieve deagglomeration in the nanofillers. Subsequently, the mixture was placed in a hot plate magnetic stirrer, and the resin was gradually added to the mixture. The temperature was increased during the process to evaporate the ethanol and decrease the viscosity of the resultant mixture. Residual ethanol was eliminated from the mixture by placing it in a hot air oven to obtain the final CNT/epoxy mixture.

The composites were synthesized using the hand layup method. Initially, the Kevlar mat was cut and cleaned with ethanol and distilled water in a sequence and dried in an oven. Subsequently, the mats were placed in a stack formation in a 300x300 millimeters mold, and a mixture of epoxy resin or CNT/epoxy mixture and hardener was dispensed over the laminas. The mold was closed and cured for 24 hours to obtain the epoxy/fiber composites.

Three composites were synthesized without and with nanofillers. The unfilled composite was used as the reference, while the other two composites that contained a 0.5 weight percentage and 1 weight percentage of CNT nanofillers were designated as KC0.5 and KC1, respectively.

Significance of the Study

Epoxy-fiber composites with and without nanofillers were synthesized successfully. Composites with nanofillers demonstrated superior impact and mechanical properties compared to composites without nanofillers. KC0.5 samples displayed significantly higher ILSS and tensile strength compared to reference and KC1 samples. The KC0.5 samples also demonstrated a considerably greater absorption of energy upon projectile impact. Moreover, the average exit velocity was lowest in the KC0.5 samples compared to other composites.

The fractographic study demonstrated that the back-side deformation was minimum in the KC1 sample, while the front side damage was lower in the KC0.5 sample as the CNT nanofillers facilitated the formation of a robust epoxy layer that shielded the impact of the projectile on the composites and the improved interfacial bonding between the fibers and matrix.

Taken together, the findings of this study demonstrated that epoxy/fiber composites with a lower amount of CNT possess superior impact properties, including ballistic performance, and can effectively reduce the low-velocity impact from small projectiles. Thus, these composites can be used in defense applications such as modern body armors.

More from AZoNano: Engineering Novel Semiconducting Ferroelectric 2D Materials

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Sukanya, N. M., Sundaram, S. K., David, A. et al. Ballistic performance of nanopowder intruded Kevlar polymeric composite targets. Materials Today: Proceedings 2022. https://www.sciencedirect.com/science/article/pii/S2214785322020624?via%3Dihub