Properties of Mo Metal and Mo Alloys

Mo is a versatile refractory metal that is easily machinable and has a high melting point, high-temperature strength (approximately 60–80 megapascals at 1500 degrees Celsius), high thermal conductivity (138 watts per meter Kelvin), and reduced neutron swelling.

However, Mo alloys exhibit limited ductility at ambient temperatures, which hinders their application. Hence, improving the ductility of Mo alloys at room temperature has been the primary objective over the past few decades.

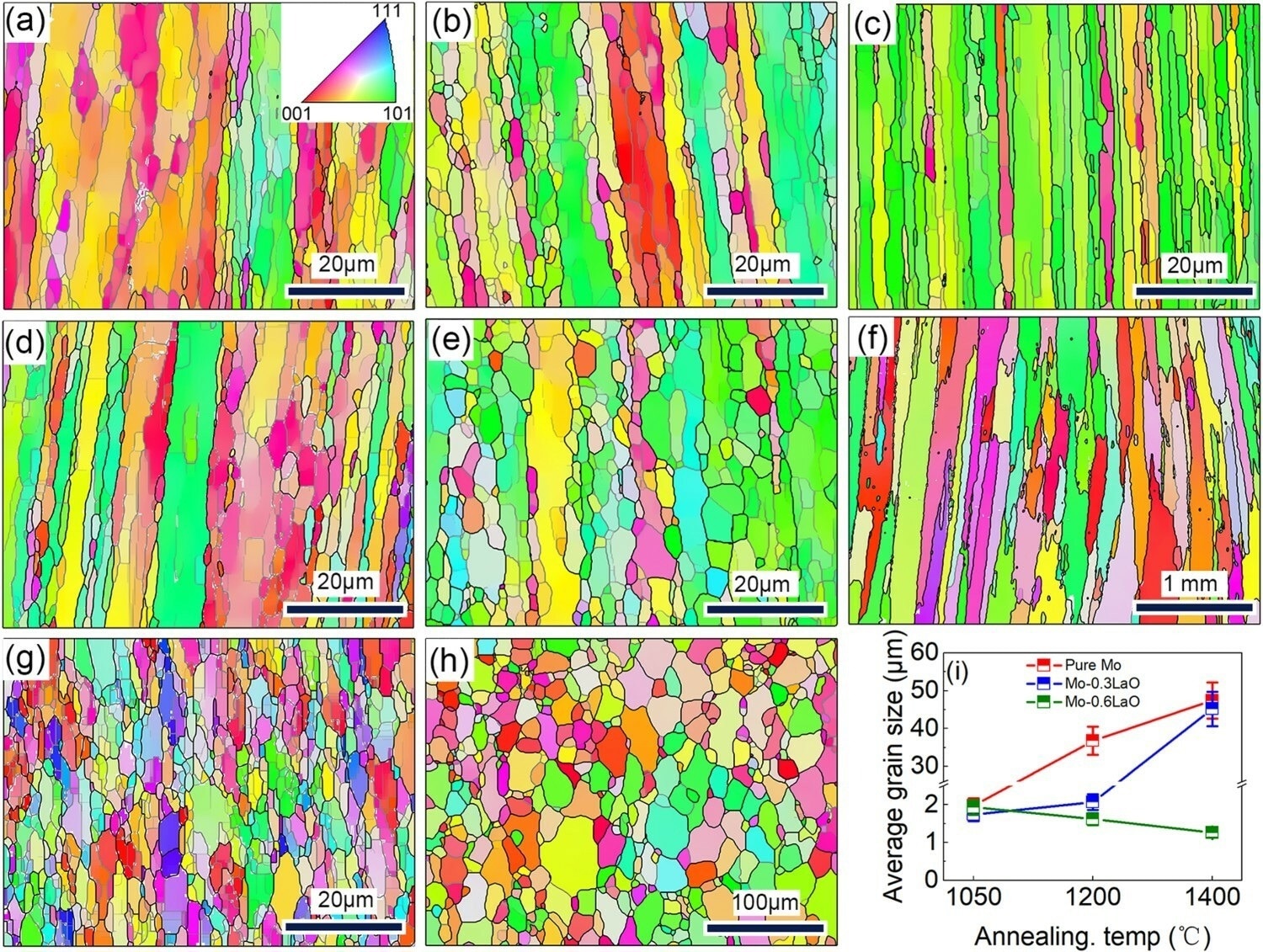

Representative EBSD IPF coloring maps of Mo-0.6LaO alloy (a–c), Mo-0.3LaO alloy (d–f), and pure Mo (g–h) annealed at Ta = 1050 °C (a,d,g), 1200 °C (b, e, h), and 1400 °C (c,f), respectively. Statistical results of the Ta -dependent average grain size are shown in (i). Image Credit: Cheng, P et al., Materials Research Letters

Consequently, a few methods have been proposed, such as the addition of a rhenium (Re) solute to improve solute softening (plastic deformation), strengthening the grain boundaries (GBs) by reducing the impurity concentration at the GBs, and incorporating second-phase particles into Mo alloys for grain refining and recrystallization.

However, the high cost of Re restricts Re-based solute softening techniques in large-scale industries. Thus, incorporating second-phase particles, such as earth oxides, has become convenient for increasing the room-temperature ductility of Mo alloys.

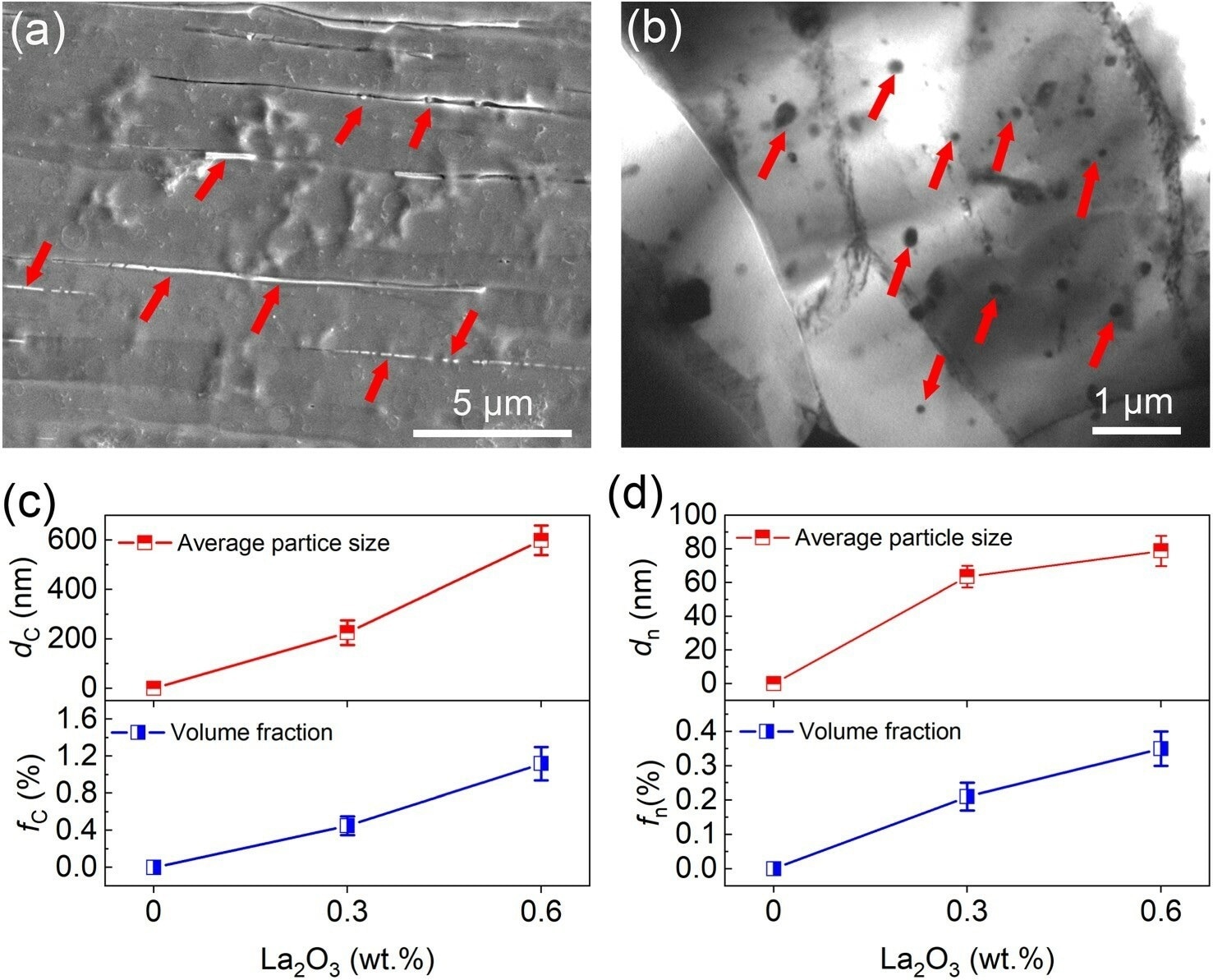

Recently, a few researchers have reported the preparation of Mo alloys with ultrafine grains and the distribution of La2O3 nanoparticles inside and at GBs. These Mo alloys with hierarchical microstructures exhibited a combination of room-temperature ductility of approximately 820 megapascals and approximately 40 % tensile elongation.

Although sub-micrograined Mo alloys with La2O3 nanoparticles have contributed to material strengthening, the underlying mechanisms associated with improved ductility remain unclear. A few reports have argued that the improved ductility is related to the reduced concentration of impurities at GBs and the enhanced dislocation accumulation caused by the pinning of nanoparticles within the grain core. However, other microstructural features, including GB characteristics, concerning the ductility mechanism in highly deformed Mo alloys remain unexplored.

With the extensive use of advanced material preparation technologies and techniques for microstructural characterization, low-angle GBs (LAGBs) have been extensively observed in metal-based high-performance materials. Here, the LAGBs were observed to play a significant role in the large plastic deformation and high thermal stability.

Representative SEM (a) and TEM (b) images to show the coarse La2O3 particles and nanosized La2O3 particles in the Mo-0.6LaO alloy, respectively. Both particles are respectively indicated by red arrows. Statistical results on the average size (dc or dn) and volume fraction (fc or fn) of the two types of particles (c: coarse La2O3, d: nanosized La2O3 particles). Image Credit: Cheng, P et al., Materials Research Letters

Ductilizing Mo Alloys by Addition of La2O3 Nanoparticles

Enhanced ductility due to the significant contribution of sub-grains was recently observed in pure tungsten (W). As the properties of W align with those of Mo, this observation in pure W metal has inspired the present study that aims to understand the Mo-La2O3 alloy’s deformation mechanisms.

In this study, Mo- La2O3 alloys were prepared via swaging technology using two different La2O3 additions (0.3 and 0.6 weight %). Subsequently, the mechanical properties and microstructural evolution of pure Mo were compared with those of prepared Mo- xLa2O3 alloys by subjecting the pure Mo metal and the alloys to different annealing temperatures. In Mo- xLa2O3 alloys, the microstructural features of Mo alloys were affected by their interactions with the incorporated La2O3 second-phase nanoparticles.

Different annealing temperatures combined with the alterations in La2O3 second-phase particles produced multi-factor-sensitive microstructures that may be attributed to the mechanical properties of Mo- La2O3 alloys, thus, revealing the deformation mechanisms.

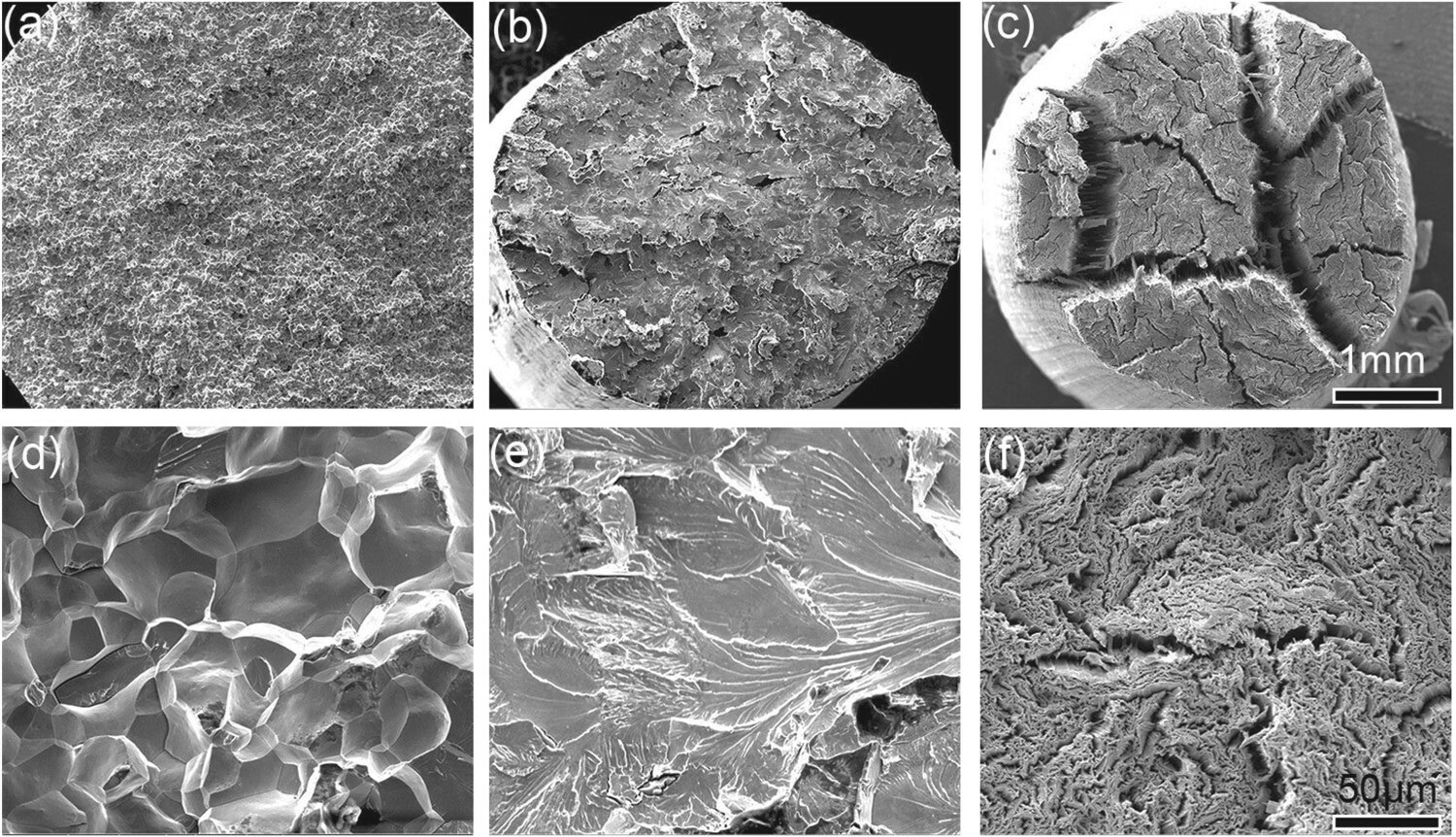

Although adding coarse La2O3 particles was found to be detrimental to ductility, dispersed La2O3 nanoparticles stabilized the deformation structures and promoted plastic deformation. Mo- La2O3 alloy with 0.6 weight % La2O3 showed ten times enhanced ductility and increased recrystallization resistance at an annealing temperature of 1400 degrees Celsius. Thus, this work highlighted the role of the hierarchical microstructure in the ductility characteristics of Mo for high performance over a wide, stable temperature range.

Representative SEM images to compare the fracture surface of pure Mo annealed at 1200 °C (a,d), Mo-0.3LaO (b,e), and 0.6 LaO (c f) at 1400 °C. Image Credit: Cheng, P et al., Materials Research Letters

Conclusion

In conclusion, the present work demonstrated that hierarchical GBs and lamellar microstructures played a significant role in the ductility properties of Mo. Although introducing coarse La2O3 particles was detrimental to ductility, adding La2O3 nanoparticles stabilized the deformation structures and increased the plastic deformation in Mo alloys.

The trade-off between the negative and positive effects was modulated by the annealing temperature, suggesting that the addition-dependent ductility varies with this value. This study emphasized the role of hierarchical microstructures in the ductility of Mo alloys for good performance and stability at an extended temperature range.

Reference

Cheng, P et al. (2022). Ductilizing Mo alloys via nanoparticle-stabilized microstructural hierarchy. Materials Research Letters. https://doi.org/10.1080/21663831.2022.2121184

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.