Image Credit: koya979/Shutterstock.com

Silicon is the gold-standard in modern-day electronics because it is a highly stable and efficient semiconductor material. It acts as an electrical conductor in certain conditions and an electrical insulator in others, allowing it to be made into a transistor—the foundation of all electronic devices. The properties and functions can be tuned and tailored to the intended application, whether the silicon-based chips are in consumer electronics or high-speed computers.

Aside from silicon properties, one of the other key reasons we have seen its use over other materials is its ease of etching and manipulation by top-down nanofabrication methods. As computer chips and electronics have advanced over the last few decades, companies have made smaller silicon chips using the latest top-down approaches.

However, there is a limit to how far you can etch, lithograph, and pattern a silicon material, and current nanofabrication methods will not be able to make silicon chips much smaller than they currently are. This is why bottom-up nanofabrication methods and nanomaterial creation from scratch (building up rather than breaking down) are seen as the future of electronics, making it possible to fabricate much smaller chips and devices.

In a world where electronics are getting smaller while retaining their efficiency (or improving on it), the ability to create smaller chips from bottom-up approaches is likely to usher in the next big revolution in electronics on a large-scale. However, this is no easy task, especially when only a handful of conductive nanomaterials can compete with silicon properties. One of these, and the frontrunner to currently displace silicon, is graphene—and it is now being trialed in several different forms.

A Potential Use for Graphene Nanoribbons

New research is emerging all the time, and one avenue currently being explored is the use of graphene nanoribbons. Single-layer (CVD) graphene has long been touted as an option for graphene electronics. However, other research suggests that graphene nanoribbons could also be the right choice for replacing silicon in electronic devices.

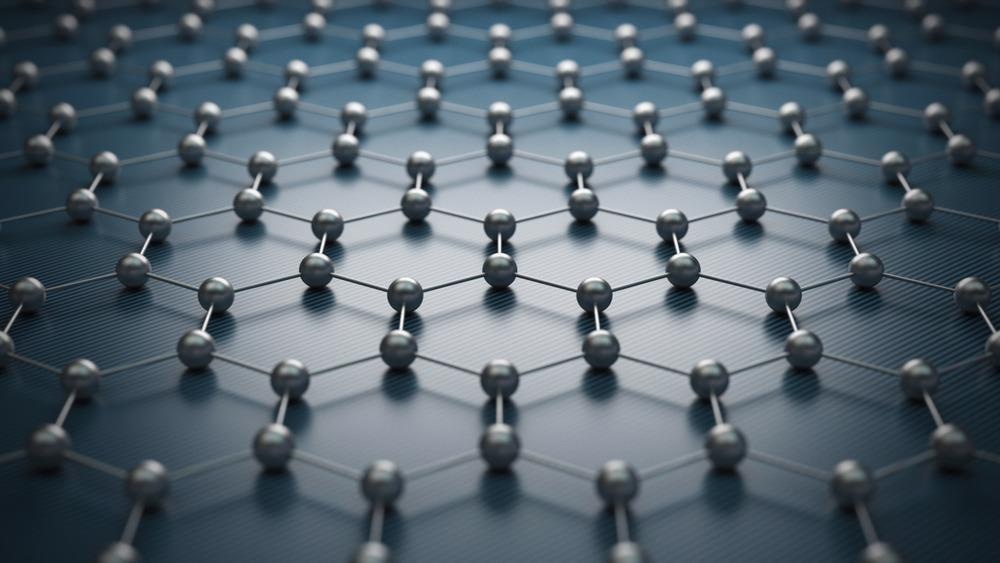

Graphene nanoribbons are exciting materials. They are essentially short, thin strips of graphene, so they do not have the lateral size of regular graphene sheets, nor are they rolled up like nanotubes. However, unlike normal graphene sheets, some of them have semiconducting properties that allow nanoribbons to be constructed into transistors.

The semiconducting properties in nanoribbons are present, providing that they are cut into the right geometry and possess no structural defects that could affect the electronic band structure across the ribbon. Researchers have been using graphene nanoribbons to make transistor devices for a while now. However, the synthesis process is more challenging to do at scale in terms of cost than other graphene forms, including CVD, which can be made using roll-to-roll methods.

Russian scientists have recently been experimenting with new self-assembly processes that are more financially feasible from a commercial standpoint. The process is a chemical vapor deposition (CVD) approach that creates graphene nanoribbons in a standard vacuum and using a cheap nickel catalyst—as opposed to an ultra-high vacuum and a gold catalyst, which is the standard procedure and both of which are responsible for the typically high cost of nanoribbon production.

The nanoribbons produced using this new method have an ultra-thin width (7 atoms) and an armchair configuration, with no apparent defects. This conformation was also found to be semiconducting, unlike wider nanoribbons, which tend to act more like a metal.

This new process has produced nanoribbons suitable for creating transistors and is a much more cost-effective method than its predecessors. It is too early to tell if graphene nanoribbons will steal the spotlight in electronics from either silicon or larger graphene sheets. If ways are found for realizing these methods and materials on larger scales, then there is the potential for another runner in the race for building next-generation electronics.

The Future of Graphene in Electronics

Graphene has many properties (in all forms) that make it an ideal material for electronic devices, ranging from its superior electrical conductivity properties to its high charge carrier mobility and its large and active surface area.

Unlike silicon, graphene does not have a bandgap, making it highly conductive. However, graphene can be doped, functionalized, and otherwise altered to induce a bandgap.

Standard graphene sheets can be manipulated to show similar properties of silicon if desired. However, as mentioned above, specific forms (such as nanoribbons) naturally show semiconducting properties without manipulation. There are many different graphene forms, providing a significant choice of materials/properties to suit the application.

Graphene has a much higher electrical conductivity and charges transfer mechanisms that lend it to being an effective medium for electronics. There are several unique benefits where graphene can be used, and silicon cannot. The sheets' thinness brings about inherent flexibility not found with silicon (or many other inorganic materials). This makes graphene a much more exciting proposition for wearable, flexible and conformal electronics.

On the subject of conformal electronics, graphene's organic nature over silicon (and other inorganic materials) means that it can be solution-processed more easily. This means that graphene sheets can be formulated into a range of mediums, such as printable inks, making graphene-based inks an excellent option as a conductive medium for printable electronics.

Will Graphene Replace Silicon in Electronics?

Graphene certainly has the potential to replace silicon in electronics, but it will be dependent on several different factors, including the willingness of end-users to adopt graphene over the status quo (and, in turn, change all their manufacturing methods). It will also rely on the graphene industry to supply enough high-quality graphene for the electronic devices—as only high-quality graphene is suitable for electronic applications.

Graphene will also have to show that it offers a better value proposition in the long term, whether this is improved performance or long-term stability compared to the cost.

The replacement of silicon will be highly dependent on companies on both sides of the industry facilitating graphene adoption on a large-scale. Even if graphene does not replace silicon in all electronics (especially lower-end cheap electronics), it is likely that the future of specialist electronics, such as printable, wearable, and flexible electronics, will be governed by graphene. This is because few alternatives can compete with the synergistic effects of both the conductive and structural (flexibility/strength) graphene properties for these devices.

References and Further Reading

Fedotov P. V. et al. (2020) Excitonic Photoluminescence of Ultra-Narrow 7-Armchair Graphene Nanoribbons Grown by a New “Bottom-Up” Approach on a Ni Substrate under Low Vacuum, The Journal of Physical Chemistry C, https://doi.org/10.1021/acs.jpcc.0c07369

Moscow Institute of Physics and Technology, Press Room [Online] Available at: https://mipt-monthly.prezly.com/material-for-future-electronics-new-method-makes-graphene-nanoribbons-easier-to-produce

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.