Sponsored by InovensoReviewed by Louis CastelMar 19 2024

The current era of health and fitness consciousness has witnessed a revolution in clothing and wearables. People are now willing to invest in attire that enhances their efficiency and promotes a well-toned physique while ensuring safety for vital organs like the lungs, especially during activities that elevate cardiac rates, such as running and hiking. The demand is for garments that facilitate higher oxygen intake without becoming soaked on the outside from the elements or wet from the inside due to sweat. This trend is evident on social media platforms, where there is a growing interest across all age groups in fitness-related content and education.

The utility of breathable waterproof fabrics extends beyond recreational activities to professional arenas such as clean rooms, the military, firefighting, and farming. Additionally, this technology holds promise in the medical field for wearable items like surgical garments, dressings, and hygiene products, suggesting a wide range of potential applications.

To meet the growing demand, fabric industries have advanced their technology, offering lightweight, breathable, waterproof fabrics that allow individuals to engage in physical activities more comfortably and for extended durations without needing to change attire. These innovations encompass products from renowned brands like Gore-Tex®, The North Face®, and Sympatex®.

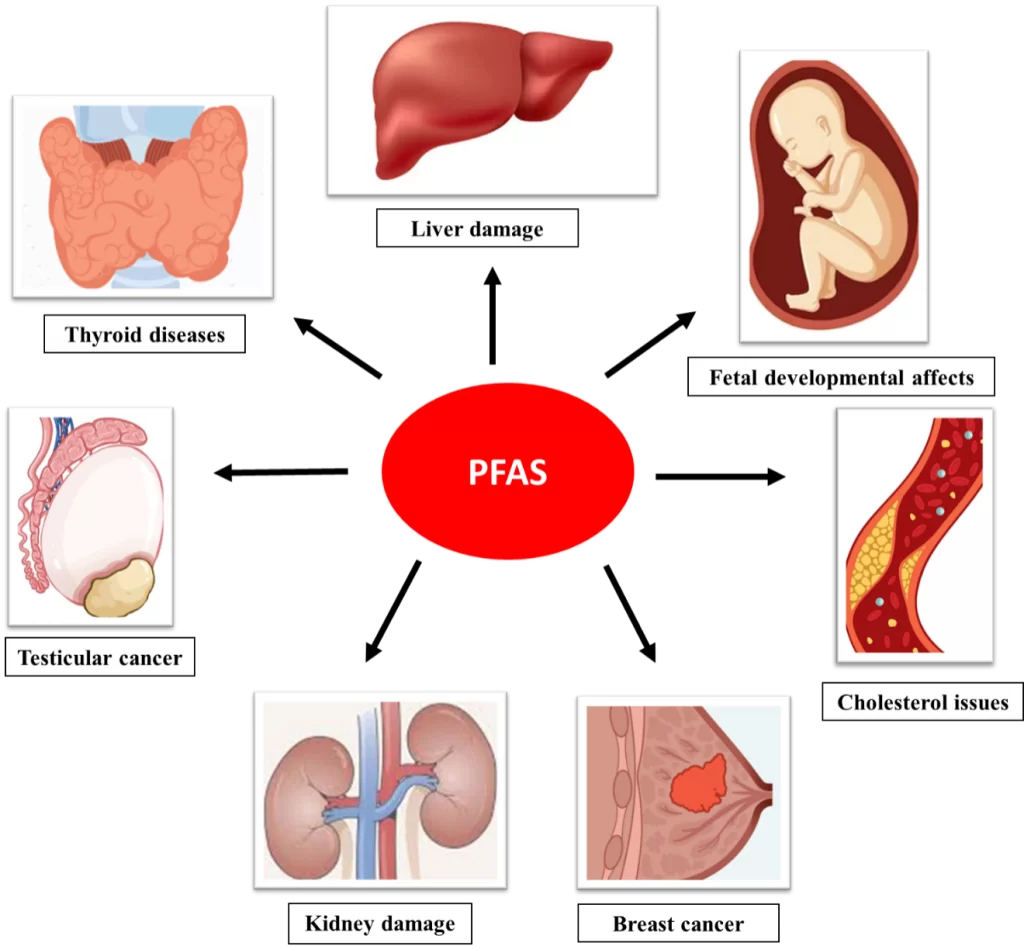

Among the numerous materials developed for wearable technology and textiles, perfluoroalkyl substances (PFAS) have seen extensive use, resulting in their accumulation in the environment and the human body. The presence of these PFAS pollutants, as highlighted by environmental organizations, such as the United Nations, OECD, HBM4EU, EEA, and documented in literature is concerning for communities due to their adverse effects, as summarized in Figure 1.1,2,3,4,5

Figure 1. Effects of Perfluoroalkyl substances on human body.4,5 Image Credit: Inovenso

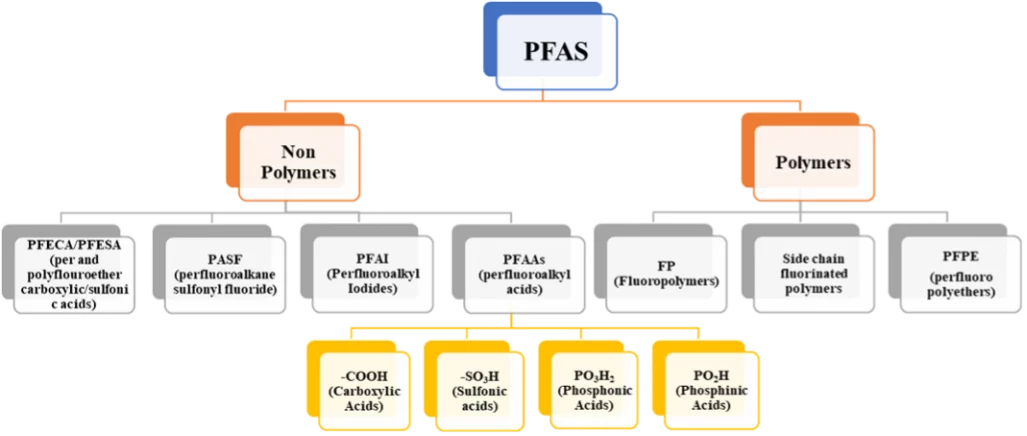

There are numerous variations of PFAS, exceeding 5000 types, which can be broadly classified as shown in Figure 2.

These substances enter the environment and human body through various pathways, including production, usage, and disposal. Their exceptional stability allows them to persist indefinitely in water sources, oceans, and soil, contaminating animal and plant ecosystems.5 Because they are non-biodegradable and natural removal mechanisms have not been developed, they are commonly called "forever chemicals."

Figure 2. PFAS and their classifications.5 Image Credit: Inovenso

A short explanation of the formation of fabrics, important factors involved, and one of the technologies to make these fabrics is provided below.

Formation and Working Mechanics

Currently, there are three ways to make a breathable, waterproof fabric: utilizing high-density woven fabrics, coated fabrics, and laminated fabrics. This article focuses mainly on laminated fabrics as they can provide both features comprehensively unlike the first two techniques of formation.

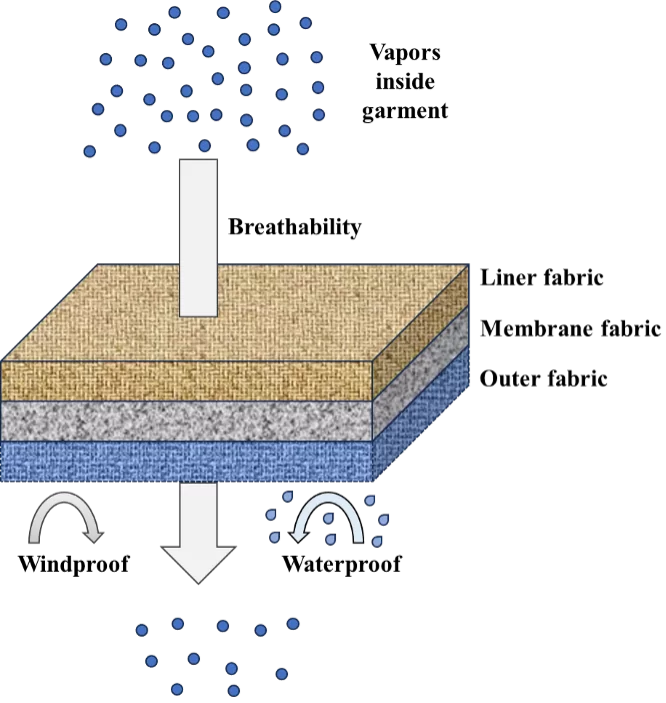

Figure 1 provides an overview of fabric construction, showcasing the three-layered scheme of lamination as an illustrative example for building breathable and waterproof fabric.

This scheme consists of a liner fabric layer in direct contact with a porous/fibrous membrane that acts as a barrier for larger molecules (vapors) while permitting smaller molecules to pass through (air).

The liner fabric functions as an inner garment and allows for the small, aerated vapors to reach the membrane interface while the athlete is perspiring. The porous structure of the membrane allows particles to penetrate based on size.

Finally, the third layer of waterproof fabric prevents external water, such as rain and snow, from passing through while allowing internal vapors to permeate and exit the fabric. Several key parameters considered during the formation of these fabrics are material hydrophilicity/hydrophobicity, permeability, porosity, mechanical strength, resistance to temperature, and the bonding or lamination of each layer to one another.

Figure 3. Scheme of a three-layered breathable waterproof fabric. Image Credit: Inovenso

Breathability

Fabric breathability refers to the capacity of water vapor to pass through fabric via diffusion, thereby facilitating personal cooling through evaporation.6 Higher levels of breathability means that more perspiration can move from the skin to the fabric's exterior, preventing moisture accumulation inside the fabric and ensuring wearer comfort.

Breathability can be measured using the moisture vapor transmission rate (MVTR), which measures the rate at which vapors can permeate a square meter of fabric within a 24-hour period, yielding a value in g/m²/day.

The suitability of fabric for specific applications is determined by its breathability rating. For instance, a rating of 5000 g/m²/day, indicating low breathability, may be suitable for fishing, whereas for mountaineering, a rating exceeding 20,000 g/m²/day is essential, given that a very high level of breathability is required.

Waterproofness

Waterproofness refers to a fabrics capacity to repel water penetration. This means that the fabric must possess sufficient porosity to prevent the passage of water droplets or bulk to flow, while allowing the passage of water vapor.6 Waterproofness is measured in terms of hydrostatic pressure in mm.

Additionally, waterproofing ratings determine the suitability of fabrics for specific applications. For example, fabrics with a rating up to 10,000 mm can withstand light rain, average snow and moderate pressure, while for values exceeding 20,000 mm are capable of enduring extreme rain, snow and high pressure.

Electrospinning for Nanofibrous Membranes

When produced using a laminated approach, traditional membrane materials like polytetrafluoroethylene (PTFE) and thermoplastic polyurethane (TPU) exhibit specific disadvantages when compared to one another.

PTFE faces challenges related to cost and recycling, whereas TPU's lack of porosity leads to diminished water permeability and subsequent discomfort. Moreover, combining both properties is very challenging, given the negative relationship between protective ability and comfort.7

In overcoming the shortcomings of conventional methods, electrospinning has introduced a novel approach for creating nanofibrous and porous membranes with high efficiency, optimized nano structures, and low weight.

The technique itself is simple. Using a high voltage, a charged spinneret dispenses a polymeric solution onto a substrate, like liner fabric. With advanced systems of electrospinning, such as the SS series from Inovenso Ltd., industrial scale continuous production of membranes laminated with fabrics is possible.8

In recent years, researchers have dedicated significant effort to enhancing membrane properties, aiming to improve vapor transmission while simultaneously addressing hydrostatic pressure concerns and avoiding the use of fluorine-based materials harmful to the environment. Additionally, there has been a focus on developing highly hydrophobic resistant membranes.

To achieve these goals, regulations on various parameters have been implemented, including processing parameters (such as voltage, deposition distance, injection flow rate, and spinneret diameter), environmental factors (such as relative humidity and temperature), and solution characteristics (including viscosity, conductivity, and surface tension). Through careful regulation of these parameters, a balance can be achieved between breathability and waterproofing capabilities.7

Material Types

In the last few years, extensive research has been conducted on various materials, such as polyurethanes (PU), polyacrylonitrile (PAN), polyvinylidene fluoride (PVDF), polyether sulfone (PES), polyimide (PI), polypropylene (PP), polymethyl methacrylate (PMMA), Nylon 6, etc., to develop optimal waterproof and breathable fabric materials.

Each of these polymers possesses unique properties that contribute to the formation of the fabrics. Often, these polymers are either blended together or combined with additional agents, such as carbon nanotubes (CNTs), silicone dioxide (SiO2), and functional fluorine.7

Products

When combined with optimized electrospinning parameters, the materials used result in products such as Futurelight© by The North Face®, which utilizes PU elastic microporous membranes.9 This innovative fabric, launched in 2019, is designed for high-exertion activities like climbing, offering waterproof and breathable performance.

The brand has also been able to manufacture PFC-free final products and utilizes treated recycled fabrics, thus enhancing its environmental friendliness. Other waterproof breathable fabric brands include DryVent®, eVent®, GORE-TEX®, and Polartec®-Neoshell®.

Applications

Waterproof and breathable fabrics applications include but are not limited to the following:

Outdoor Gear: Hats, gloves, umbrellas, dry suits, and tents.

Construction: Roofing materials, owing to their light-weight properties, as well as water resistant, UV resistant, and acoustic insulation.

Medical Supplies: Pillow covers, bed covers, surgical garments, and wound dressings.

Agriculture: Tree shelters and packaging for product transportation.

Professional: Protective military wear, functional heavy-duty wear, clean room clothing, firefighting kits, and farming apparel.

Sportswear: Jackets, trousers, raincoats, swimwear, rainwear, skiwear, footwear, trekking shoes, and camping boots.

Future Directions

As discussed in this brief article, there is immense potential for developing optimal waterproof breathable fabrics through careful selection of material types, particularly polymers that strike the right balance between breathability, waterproofness, and comfort for prolonged wear.

Given the industry's shift toward PFC-free products due to their detrimental environmental impact and slow degradation, the choice of material holds significant importance.

The choice of fabric formation is also key for newer technologies, with electrospinning being at the forefront in achieving high-precision, optimally porous nanofibers at a very high production rate. The technique offers flexibility by enabling the direct deposition of novel fibers with multifunctional propertied, such as liner fabric. Moreover, it reduces the need for extensive post-processing, resulting in a more efficient transition to the final finished product form.

Acknowledgments

Produced from materials originally authored by Waleed Mustafa.

References and Further Reading

- Stockholm Convention. UNEP/POPS/POPRC. 14/6 (Meeting report).

- OECD. [Online] Portal on Per and Poly Fluorinated Chemicals. Available at: https://www.oecd.org/chemicalsafety/portal-perfluorinated-chemicals/ (Accessed on: unknown)

- https://www.hbm4eu.eu/hbm4eu-substances/per-polyfluorinated-compounds/

- EEA. [Online] Emerging chemical risks in Europe — ‘PFAS’. Available at: https://www.eea.europa.eu/publications/emerging-chemical-risks-in-europe/emerging-chemical-risks-in-europe (Accessed on: unknown).

- Brennan, N.M., et al. (2021). Trends in the Regulation Of Per- And Polyfluoroalkyl Substances (PFAS): A Scoping Review. International Journal of Environmental Research and Public Health. doi.org/10.3390/ijerph182010900

- McCullough, E.A., et al. (2003). A Comparison of Standard Methods For Measuring Water Vapour Permeability of Fabrics. Measurement Science and Technology. doi.org/10.1088/0957-0233/14/8/328

- Sheng, J., Zhao, J., Yu, X., Liu, L., Yu, J., & Ding, B. (2019). Chapter 17 - Electrospun Nanofibers for Waterproof and Breathable Clothing. Electrospinning: Nanofabrication and Applications, pp. 543-570. https://www.sciencedirect.com/science/article/abs/pii/B9780323512701000170

- Inovenso. [Online] Homepage. Available at: https://www.inovenso.com/ (Accessed on: unknown)

- The North Face. [Online] Homepage Available at: https://www.thenorthface.co.uk/ (Accessed on: unknown)

This information has been sourced, reviewed, and adapted from materials provided by Inovenso.

For more information on this source, please visit Inovenso.