Dec 21 2012

MIT researchers now have new insights into how 'stress corrosion cracking' may be affected by nanoscale disruptions in the crystalline structure of metallic materials.

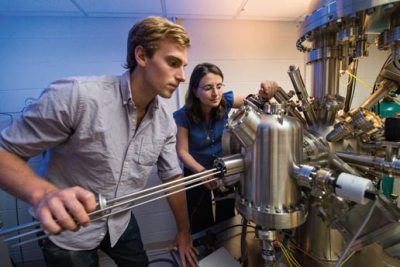

F. William Herbert of materials science and engineering (left) and Bilge Yildiz of nuclear science and engineering are examining how nanoscale disruptions in the crystalline structure of metals affect those materials’ vulnerability to stress corrosion cracking. (Image: Justin Knight)

F. William Herbert of materials science and engineering (left) and Bilge Yildiz of nuclear science and engineering are examining how nanoscale disruptions in the crystalline structure of metals affect those materials’ vulnerability to stress corrosion cracking. (Image: Justin Knight)

High stresses combined with a corrosive environment can cause critical components inside power plants and other systems to crack and fail, sometimes with little warning. MIT researchers now have new insights into how such "stress corrosion cracking" may be affected by nanoscale disruptions in the crystalline structure of metallic materials. Using novel experimental methods, they showed that mismatches between adjacent crystals can create regions with altered mechanical properties, including hardness. In addition, those defects can change the electronic properties of the surface in the region, making reaction with oxygen more likely and accelerating the pace of corrosion. Ultimately, the MIT researchers hope to define nanostructures that can help prevent this pervasive, insidious form of material degradation and failure.

Nuclear power plants are designed for decades of operation. But finding materials that age well in the extreme environment inside an operating plant is difficult. A major problem is stress corrosion cracking, which combines chemical attack in the form of corrosion with stress from mechanical loads. "Corrosion causes a material to age in a particular manner and speed, and stress causes it to fracture after a certain period of time," says Bilge Yildiz, associate professor of nuclear science and engineering. "But when you have those two processes together, they interact, and both processes are accelerated." Worse still, the damage often is not obvious, so failure can be both unexpected and catastrophic. Stress corrosion cracking has been blamed for failing power plants, exploding natural gas pipelines, collapsing bridges, crashing airplanes, and more.

One challenge is that local structures in a material can make it more vulnerable to both fracture and chemical attack. Many of the most advanced materials for power plant components are polycrystalline, that is, made up of many tiny crystals, or "grains." The atoms inside each grain are lined up in a regular pattern. But neighboring grains within a solid may be oriented in different directions, so rows of atoms can be misaligned where two or more grains meet. According to one hypothesis, misalignments at those grain-to-grain interfaces—the "grain boundaries"—can affect the material's local response to stress and can create dislocations in the crystalline structure nearby that are more chemically reactive with oxygen and are thus more likely to corrode.

Yildiz, head of MIT's Laboratory for Electrochemical Interfaces, notes that carefully controlled processing conditions can produce materials with grains of pre-defined sizes and orientations. "So if we had a better understanding of the relationship between grain-boundary structure, response to mechanical stress, and resistance to corrosion, we might be able to create a surface structure or texture that would help inhibit stress corrosion cracking," she says.

But even after decades of corrosion research, there is still no conclusive picture of the processes going on at the grain boundaries. Part of the problem is that the effect is extremely local. "A grain boundary extends over only one or a few nanometers, so it's a confined medium," says Yildiz. "And it's a coupled chemical-mechanical degradation mode. So we needed new, high-resolution tools to reach the mechanical as well as chemical properties of these localized structures."