The 3D printing industry is changing rapidly, thanks to JEOL USA, Inc. and Additive. The two companies are working in conjunction to innovate additive manufacturing at an unprecedented speed.

JEOL's electron beam metal AM machine allows for the efficient and clean production of lighter manufactured parts for usage in the aerospace and energy sectors. It enhances output and shortens development time by enabling high-quality, highly repeatable modelling, integrating multiple components, and reducing overall weight.

JEOL Additive Manufacturing Technology

Image Credit: JEOL USA, Inc.

Drawing on technology from its world-leading electron microscopes and electron beam lithography systems used in semiconductor manufacturing, JEOL has developed an Electron Beam Metal Additive Manufacturing (AM) machine that outperforms conventional laser-based systems in power, density, and speed. The system boosts production efficiency, offering greater design flexibility and significant cost savings.

JAM-5200EBM

Long Life Cathode over 1,500 Hours and Helium-Free Electron Beam Metal AM Machine

Main Features

- A Remote Monitoring System

- Realization of an eco-friendly and sustainable society

- JEOL USA established an extensive service support organization

- Long Life Cathode

- Helium-Free and powder dispersal prevention system "e-Shield"

- Automatic Electron Beam Correction

The JEOL Advantage for Additive Manufacturing

- The system is designed for maximum uptime and features a cathode with a lifespan exceeding 1,500 hours. A controlled, clean manufacturing environment helps preserve cathode integrity while ensuring consistent production quality.

- The system operates in a helium-free atmosphere and features an “e-shield” that prevents smoke generation during manufacturing. JEOL’s innovative powder dispersal prevention mechanism also eliminates particle scattering, ensuring a cleaner and more stable build process.

- The focus and spot form of the electron beam are automatically corrected based on the irradiation position. This technique was developed in-house, using our market leadership in electron beam lithography equipment for semiconductor fabrication.

- This system can remotely monitor conditions and manufacturing status

- JEOL is an environmentally friendly manufacturer: the system can generate multiple parts in a single run.

- Manufacturing capacity of 250 mm (diameter) × 400 mm (height).

- JEOL USA’s existing large service network includes over 180 field service engineers.

A 3D Printer Built on JEOL Expertise and Support

The JEOL JAM-5200EBM stands out in this emerging field because it is backed by JEOL's decades of experience developing and manufacturing superior electron optics technology for research and industrial applications.

JEOL is the global leader in electron microscopy instruments and is already contributing to the value stream of 3D printing through materials characterization, particle analysis, imaging, and chemical analysis. The JAM-5200EBM's electron beam technology is based on JEOL's 50-plus-year expertise in developing and producing generations of mask writing and spot beam lithography tools using proprietary vacuum technology.

Long Life Cathode

Image Credit: JEOL USA, Inc.

The Long Life Cathode significantly reduces the need for cathode replacement. The secret behind its 1,500-hour lifetime is JEOL's original vacuum technology, which was created for the manufacture of electron beam-related equipment.

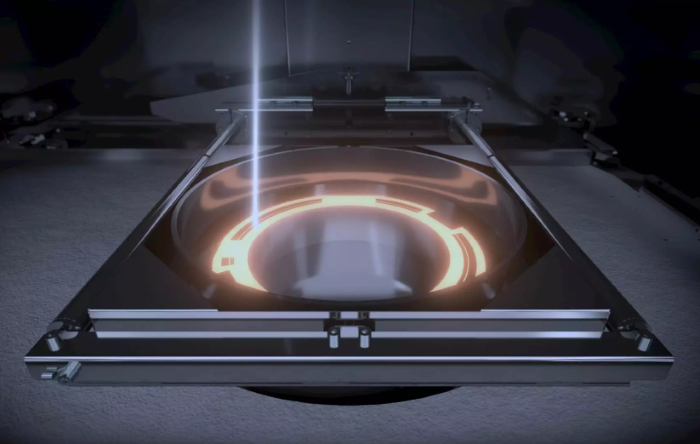

Helium-Free and Powder Dispersal Prevention System "e-Shield"

Image Credit: JEOL USA, Inc.

With JEOL's special powder dispersal avoidance mechanism the scattering phenomenon is avoided, and there is no need for helium gas to stop powder from scattering. As a result of this helium-free environment, “the surface of the cathode is also less susceptible to damage, allowing the electron beam to remain stable.” This allows the manufacturing quality to be preserved until the cathode's life is over.

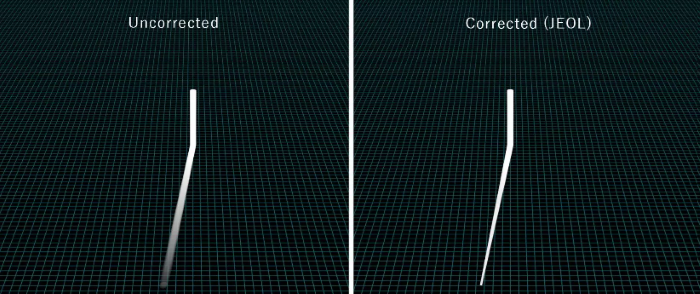

Automatic Electron Beam Correction

Image Credit: JEOL USA, Inc.

The technology developed in the electron beam lithography equipment for semiconductor production automatically corrects the focus and spot form of the electron beam according to the irradiation position.

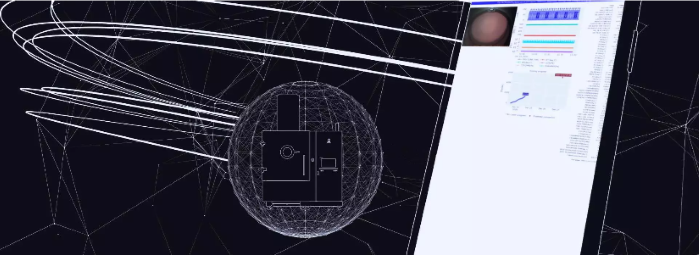

Remote Monitoring System

Image Credit: JEOL USA, Inc.

The manufacturing status and machine conditions can be monitored from a distant place at any time. An alarm notification feature can also be added.

Realization of an Eco-Friendly and Sustainable Society

Image Credit: JEOL USA, Inc.

Using JEOL's Electron Beam Metal AM Machine, multiple parts can be created in a single printing session, and almost no cutting is required, which reduces waste. Waste can be further reduced by reusing the metal powder. JEOL has designed its machine as part of its objective to create an environmentally friendly and sustainable society.

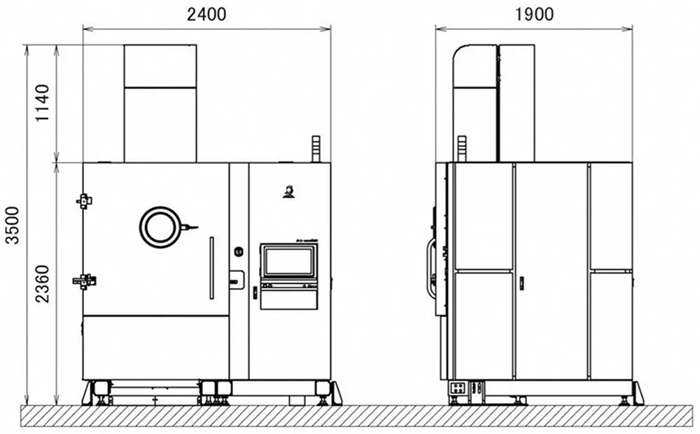

JAM-5200EBM Technical Data

Main Specifications. Source: JEOL USA, Inc.

| |

|

| Manufacturing method |

Powder bed fusion |

| Manufacturing dimensions |

Maximum 250 mm (Dia.) × 400 mm (H) |

| Electron beam output |

Maximum 6 kW |

| Lifetime of cathode |

1500 h or longer |

| Chamber pressure (during melting) |

0.01 Pa or lower |

| Inert gas (for charging prevention) |

Not required |

| Manufactured product cooling system |

Equipped |

| Powder dispersal prevention system |

e-Shield |

| Beam correction |

Automatic (Focus, Astigmatism, Distortion) |

| Power supply |

3-phase, 200 V (±10%), 35 kVA |

| Weight |

4900 kg |

| Data format |

STL |

Image Credit: JEOL USA, Inc.